Preparation method for sensing type warp knitting dacron geogrid coated with conductive phase material

A technology of warp-knitted polyester and geogrid is applied to the device, coating, fiber type and other directions of coating liquid on the surface. Cost of inspection and maintenance, convenience of quality inspection, effect of strengthening geotechnical structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing a sensor-type warp-knitted polyester geogrid coated with a conductive phase material, comprising the following steps:

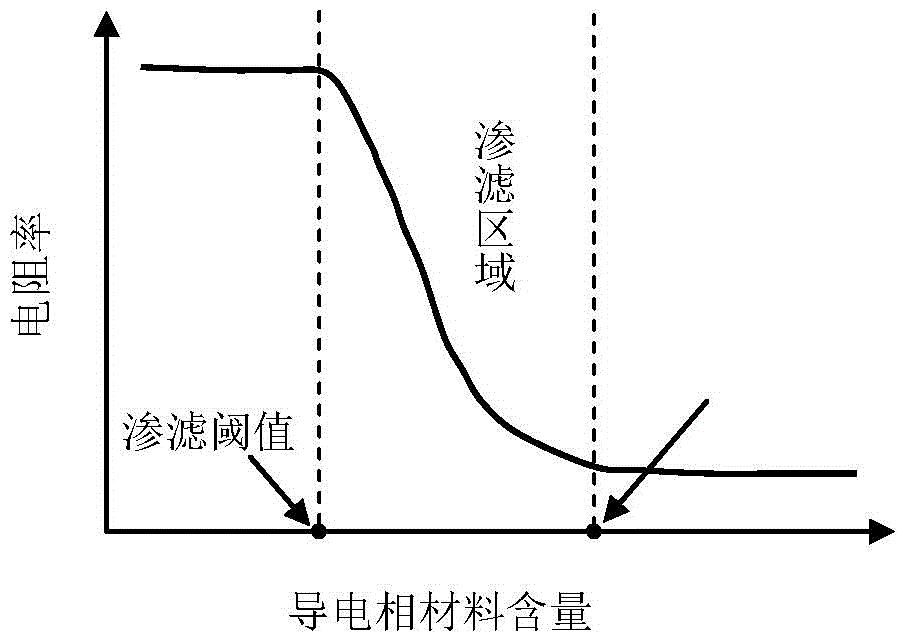

[0027] Step 1 Select conductive phase solvents, additives and conductive phase materials according to construction conditions and market costs, and select a relatively significant ratio in the percolation area as raw materials for the preparation of warp-knitted polyester geogrid.

[0028] Step 2 prepares conductive fiber coating solution;

[0029] Step (2-1) prepares plastisol;

[0030] Step (2-2) prepares conductive phase material powder;

[0031] Step (2-3) dissolving the powder of the conductive phase material in the plastisol;

[0032] Step (2-4) grinding and dispersing;

[0033] Step (2-5) adding a good adhesive to effectively bond the coating material and the geosynthetic material;

[0034] Step (2-6) grinds evenly;

[0035] The preparation process of described step (2-1) plastisol is as follows:

[0036] Taking poly...

example 1

[0046] In road engineering, geogrids are mainly used to reinforce soil and prevent settlement. In order to prepare the sensor-type warp-knitted polyester geogrid suitable for roads, carbon black will be used as the conductive phase material (the relationship between resistivity and strain is Taking PVC as the matrix, adding plasticizer dioctyl phthalate, heat stabilizer barium stearate and other additives, melting and kneading to form a sensor-type conductive coating solution, and then dipping the warp-knitted polyester grid in In the coating solution, the required road-sensing warp-knitted polyester grid is formed. Laying this type of geogrid in the subgrade can not only strengthen the subgrade and prevent settlement, but also perform positioning detection and preventive maintenance through the resistance value change after stress deformation, which can save a lot of money and reduce Work volume.

example 2

[0048] During mine production operations, the stability and firmness of the roadway is the guarantee of safe production. To reinforce the roadway, geonets are usually buried, which not only improves the robustness of the roadway, but also reduces construction costs. But even so, due to the effect of confining pressure and other factors, the roadway wall will still be deformed and damaged, resulting in loss of life and property. If special equipment is used for regular inspection, it will be time-consuming, laborious and inconvenient to operate. The above problems can be solved by laying sensor-type warp-knitted polyester geonet. Use polyvinyl chloride resin as the matrix, melt and knead carbon black powder as the conductive phase filler, add plasticizer, heat stabilizer, dispersant, and adhesive to make the coating material, and immerse the warp-knitted polyester grid into the In the coating solution, take it out and wait for it to air-dry and solidify to form a sensory warp-k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com