Sulfuric acid tail gas recovery device

A technology of sulfuric acid tail gas and recovery device, which is applied in the fields of sulfur compounds, inorganic chemistry, dispersed particle separation, etc., can solve the problems of absorbents that cannot be recycled or used, and achieve the effect of improving the recycling rate and realizing the recycling utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

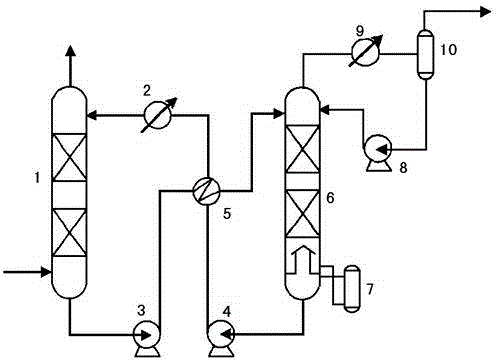

[0014] Specific embodiment: as shown in the figure, it is the structural representation of the device of the present invention, sulfuric acid tail gas enters absorption tower 1, and the SO in the tail gas 2 It is absorbed by the solvent in the absorption tower 1, and the tail gas after desulfurization is emptied from the top of the tower to absorb SO 2 The final rich liquid enters the lean / rich liquid heat exchanger 5 from the rich liquid pipeline at the bottom of the tower through the rich liquid pump 3, and enters the upper part of the regeneration tower 6 after recovering heat. The rich liquid enters from the upper part of the regeneration tower 6 and desorbs part of the SO 2 , and then into the reboiler 7, so that the SO 2 Further desorption, the desorbed SO 2 Together with the water vapor, after being cooled by the condenser 9, the moisture is removed by the gas-liquid separator 10 to obtain pure SO 2 , the condensed water separated by condensation is sent to the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com