Special silicon containing compound fertilizer for paddy and preparation method of said fertilizer

A compound fertilizer and rice technology, applied in the direction of urea compound fertilizer, nitrogen fertilizer, application, etc., can solve problems such as negative impact on soil, achieve the effects of reducing labor costs, protecting the environment, and improving lodging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

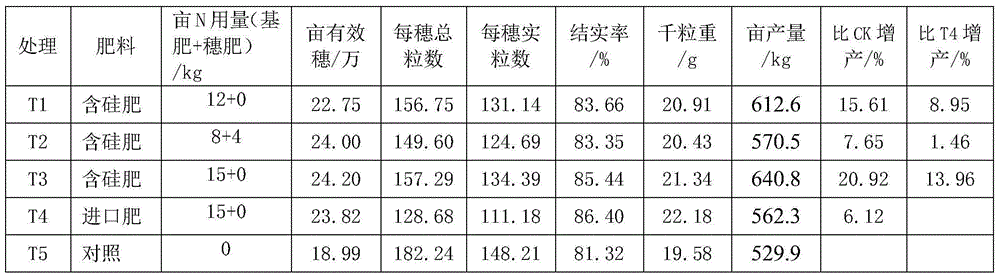

Image

Examples

Embodiment 1

[0023] Add 7 parts by weight of urea granules to the coating pan, make it rotate at a constant speed of 20 rpm, spray 0.005 parts by weight of dilute sulfuric acid (mass concentration of 2%) on the surface of the urea to make the urea wet; add to the urea 0.05 parts by weight of magnesium oxide powder, uniformly attached to the surface of the urea; add 2.95 parts of 200-400 mesh slag powder with an effective silicon content of 30% to the urea, and keep the coating pot rotating at a constant speed until the slag powder is completely wrapped on the surface of the urea, and the result will be The fertilizer is dried to obtain coated slow-release urea.

[0024] The above-prepared coated sustained-release urea, commercially available diamine phosphate and commercially available 60% red potassium according to 1:

[0025] 0.33:0.49 by weight ratio to obtain silicon-containing slow-release compound fertilizer special for rice, in which the total nutrient content is 45.4%, and slow-release ...

Embodiment 2

[0027] Add 6 parts by weight of urea granules to the coating pan, make it rotate at a constant speed of 20 rpm, spray 0.0006 parts by weight of polyvinyl alcohol on the surface of the urea to make the urea wet; add 1.4 parts by weight of attapulgite powder to the urea , Uniformly adhere to the surface of urea; add 2.4 parts of 200-400 mesh steel slag composite powder with 20% effective silicon content to urea, and keep the coating pot rotating at a constant speed until the steel slag composite powder is completely wrapped on the surface of urea, and the obtained fertilizer After drying, the coated sustained-release urea is obtained.

[0028] The prepared coated slow-release urea, commercially available diamine phosphate, and commercially available 60% red potassium were mixed in a weight ratio of 1:0.22:0.54 to obtain a silicon-containing slow-release compound fertilizer for rice, in which the total nutrient content was 42.8 %, slow-release nitrogen fertilizer accounts for 56.8% ...

Embodiment 3

[0030] The preparation of coated sustained-release urea is the same as in Example 2.

[0031] Coated slow-release urea, commercially available diamine phosphate, and commercially available 60% red potassium were mixed in a ratio of 1:0.35:0.51 to obtain a silicon-containing slow-release compound fertilizer special for rice. The total nutrient content is 43.2%, slow-release Nitrogen fertilizer accounts for 53.8% of which N, P 2 O 5 And K 2 The content of O is 18.2%, 8.5% and 16.5%, and the effective silicon content is 2.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com