A kind of quaternary copolyester fiber and preparation method thereof

A quaternary copolyester and fiber technology, which is applied in the field of polyester fiber, can solve the problems of fiber hygroscopicity and insignificant improvement of coloring property, and achieve the improvement of hydrophilicity and dyeability, and the improvement of hydrophilicity and dyeability , Improve the effect of spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

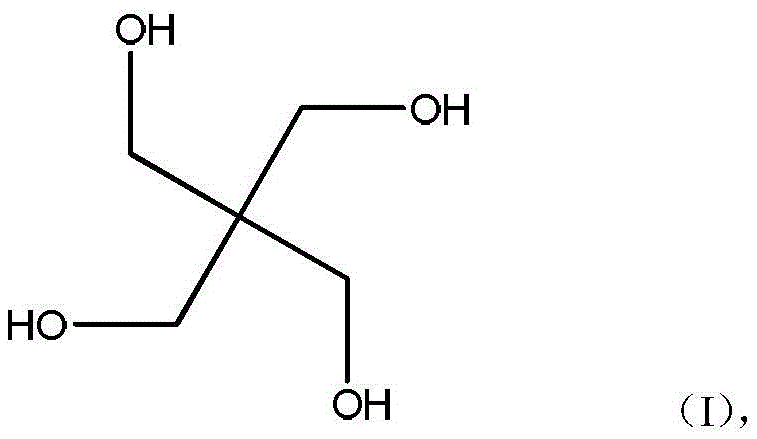

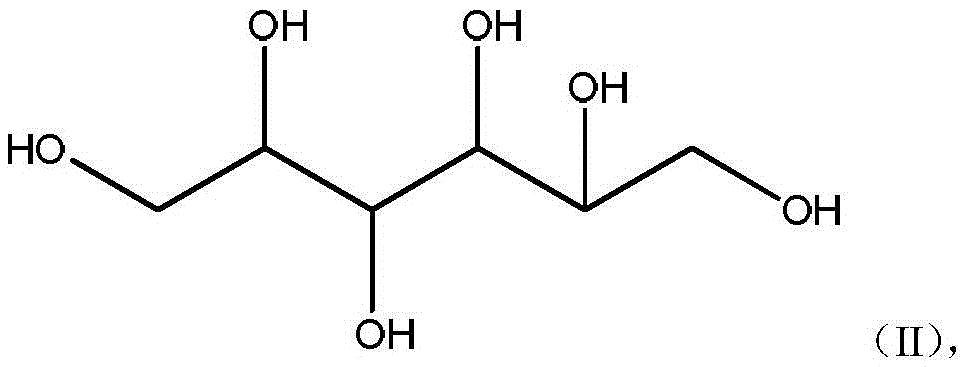

[0027] (1) beating: get 744.0g (12mol) ethylene glycol and sorbitol 2.9g (0.016mol), pentaerythritol 2.9g (about 0.021mol) dissolve and mix, then mix its mixture with the PTA of 1660g (10mol), add catalyst Ethylene glycol antimony 20g, stabilizer trimethyl phosphate 4g, stir well, and transport to the esterification kettle;

[0028] (2) Esterification: carry out continuous esterification in the esterification (I) and (II) kettles, the esterification temperature is controlled at 240 ° C, the pressure is 100KPa, the esterification rate reaches more than 93.5%, and is transported to the polycondensation kettle;

[0029] (3) Polycondensation: during polycondensation, the polycondensation temperature is controlled at 280°C, vacuumed to 60MPa, and polycondensation to the target viscosity (intrinsic viscosity 0.66);

[0030] (4) The molten quaternary copolyester is sent to a filter for filtration to obtain quaternary copolyester fibers. After metering, it enters the spinning assembly...

Embodiment 2

[0033] (1) beating: get 744.0g (12mol) ethylene glycol and sorbitol 7.8g (0.048mol), pentaerythritol 5.8g (about 0.042mol) dissolve and mix, then mix its mixture with the PTA of 1660g (10mol), add catalyst Ethylene glycol antimony 10g, stabilizer trimethyl phosphate 4g, mix well, and transport to the esterification kettle;

[0034] (2) Esterification: carry out continuous esterification in the esterification (I) and (II) kettles, the esterification temperature is controlled at 237 ° C, the pressure is 100KPa, the esterification rate reaches more than 93.5%, and is transported to the polycondensation kettle;

[0035] (3) Polycondensation: during polycondensation, the polycondensation temperature is controlled at 270°C, vacuumed to 80MPa, and polycondensation to the target viscosity (intrinsic viscosity 0.65);

[0036] (4) The molten quaternary copolyester is sent to the filter for filtration to obtain quaternary copolyester fibers. After metering, it enters the spinneret assemb...

Embodiment 3

[0039] (1) Beating: get 744.0g (12mol) of ethylene glycol and 5.8g (0.032mol) of sorbitol, 0.29g (0.021mol) of pentaerythritol, dissolve and mix, then mix the mixture with 1660g (10mol) of PTA, add a catalyst Ethylene glycol antimony 2g, stabilizer trimethyl phosphate 0.4g, stir well, and transport to the esterification kettle;

[0040] (2) Esterification: continuous esterification is carried out in the esterification (I) and (II) kettles, the esterification temperature is controlled at 239 ° C, the pressure is 100KPa, the esterification rate reaches more than 93.5%, and is transported to the polycondensation kettle;

[0041](3) Polycondensation: During polycondensation, the polycondensation temperature is controlled at 290°C, vacuumed to 40MPa, and polycondensed to the target viscosity (intrinsic viscosity 0.67);

[0042] (4) The molten quaternary copolyester is fed into the filter to filter to obtain the quaternary copolyester fiber. After metering, it enters the spinneret a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com