Intelligent inspection robot system of convertor station valve hall

A robot system and intelligent inspection technology, applied in inspection time patrol and other directions, can solve the problems such as the inability to replace the battery at any time in the closed space of the valve hall, the inability of the mobile robot to complete the work requirements, and the inability to use the portable battery power supply method to achieve long-term Continuous inspection work, to achieve large stroke detection requirements, the effect of high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

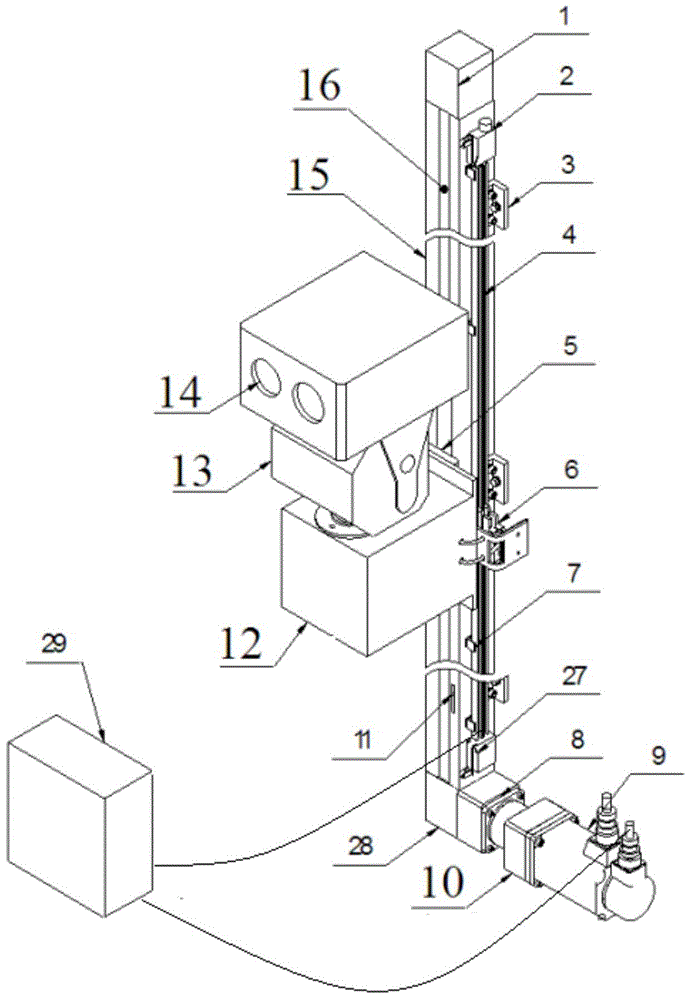

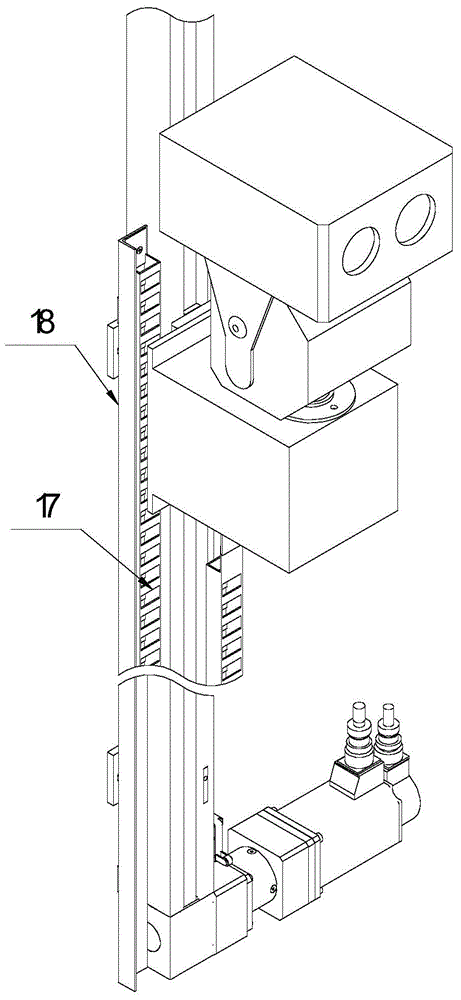

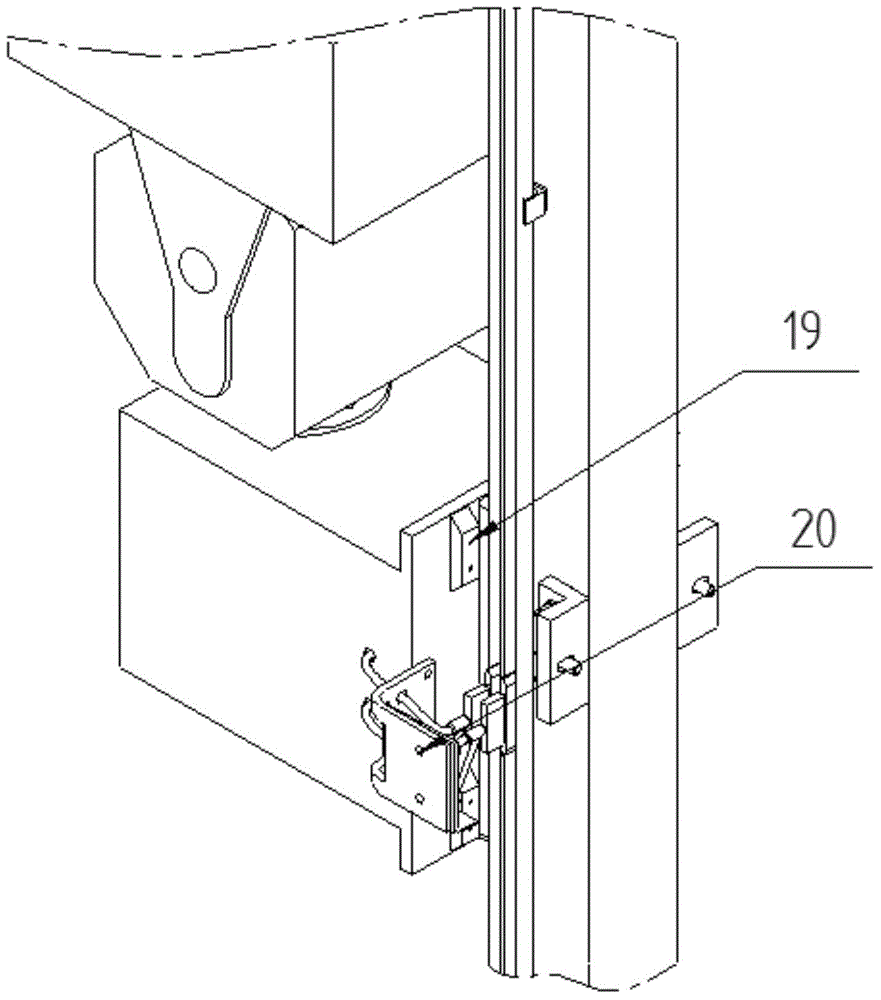

[0075] Such as figure 1 As shown, the intelligent inspection robot system for the valve hall of the converter station includes a remote control system and a robot terminal system. The robot terminal system 42 communicates with the remote control system 41. Installed directly on the wall of the valve hall, the profile track 15 is equipped with a motion mechanism, a motion drive mechanism and a detection mechanism;

[0076] The motion mechanism includes a first synchronous pulley assembly 1, a second synchronous pulley assembly 28 and a synchronous belt 16. The synchronous pulley assembly includes a synchronous pulley box and a synchronous pulley, and the synchronous pulley box is installed on the profile The upper and lower ends of the track 15, the synchronous pulley is installed inside the synchronous pulley box, and the synchronous belt 16 is tightly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com