Electrode composite material, preparation method thereof, anode possessing the electrode composite material and cell

A technology of composite materials and electrodes, applied in non-aqueous electrolyte batteries, nanotechnology for materials and surface science, battery electrodes, etc., can solve problems such as loss of active materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method of an electrode composite material, the preparation method comprising the following steps: mixing an M13 phage suspension with an elemental sulfur water dispersion solution, encapsulating the mixture and drying to obtain an M13 phage / sulfur electrode composite material.

[0030] In a specific embodiment, the volume ratio of the M13 phage suspension to the elemental sulfur water dispersion solution is 20:1˜30:1. Further preferably, the volume ratio of the M13 phage suspension to the elemental sulfur water dispersion solution is 25:1.

[0031] In a specific embodiment, the mass percentage of elemental sulfur in the aqueous dispersion of elemental sulfur is 8% to 12%, and more preferably, the mass percentage of elemental sulfur in the aqueous dispersion of elemental sulfur is 10%. Preferably, the elemental sulfur water dispersion solution is a nanometer elemental sulfur water dispersion solution.

[0032] In a specific embodiment, the mixing is realiz...

Embodiment 1

[0058] Preparation of the electrode composite material: Add 10 mL of M13 phage suspension to the centrifuge tube, then add 400 μL of 10% by weight nanometer elemental sulfur water dispersion solution to the centrifuge tube, shake the table for 2 hours to mix evenly, use The centrifuge tube was packaged, and the centrifuge tube was placed in a conventional oven at 70° C. to dry for two days to obtain the M13 phage / sulfur electrode composite material.

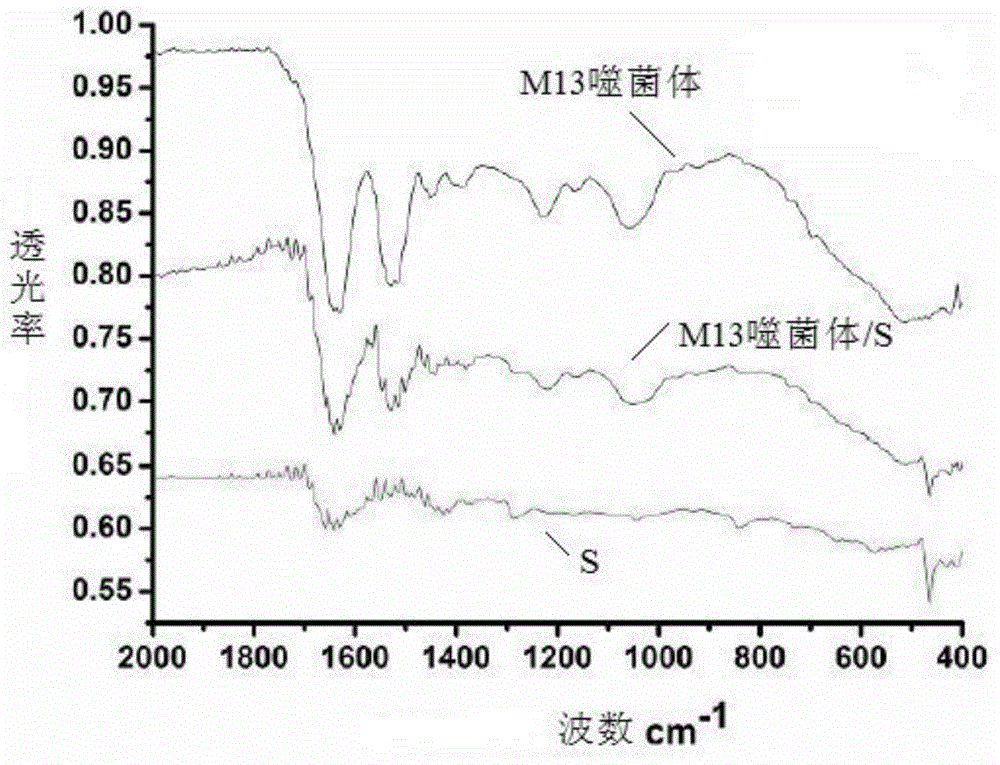

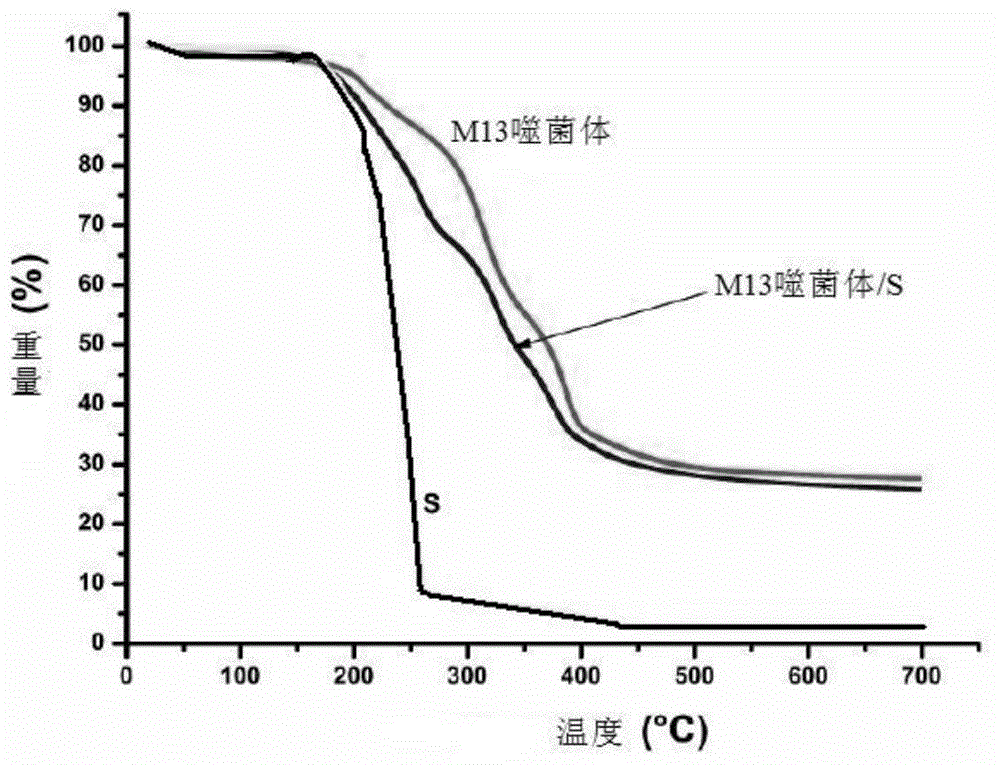

[0059] figure 1 It is the infrared spectrogram of nano elemental sulfur, M13 phage and M13 phage / sulfur electrode composite. It can be seen from the figure that the infrared spectrum of the M13 phage / sulfur electrode composite material shows the combined characteristic bands of pure M13 phage and nanometer elemental sulfur. The combined infrared spectrum indicates that elemental sulfur may be embedded in the M13 phage, That is to say, in the M13 phage / sulfur electrode composite material, a good binding effect is formed between ...

Embodiment 2

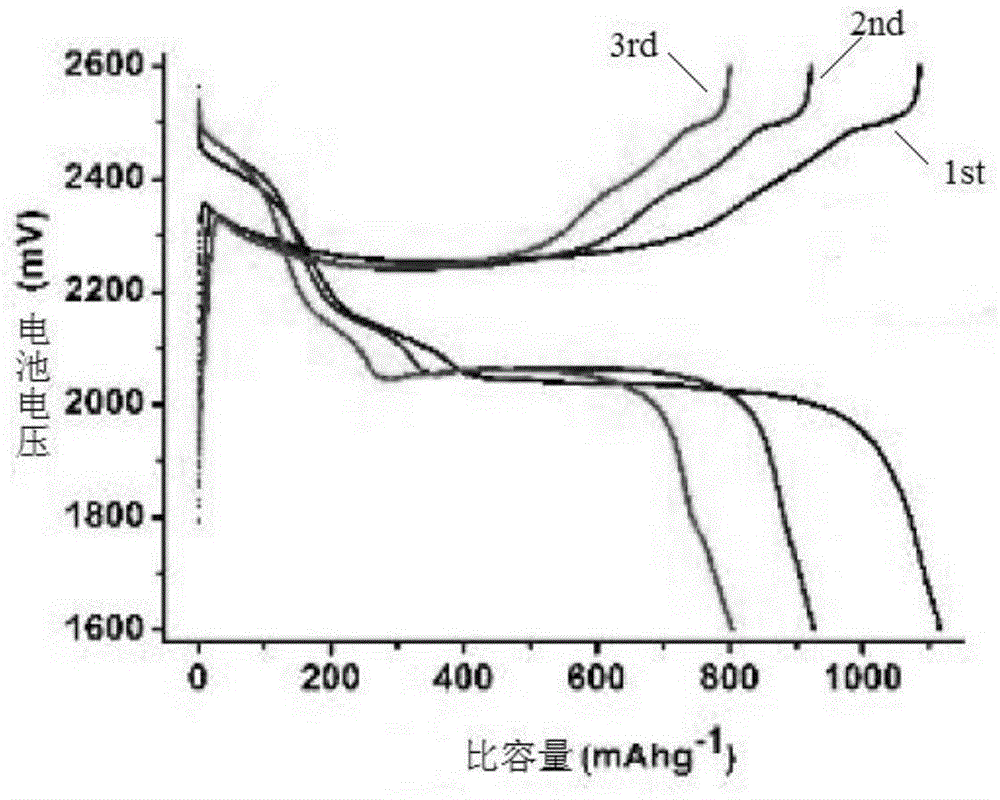

[0062] The preparation of positive electrode: be the M13 phage / sulfur electrode composite material in the embodiment 1 of 80% by weight percentage, the polyvinylidene fluoride (PVdF) (Kynar, HSV900) (Kynar, HSV900) and weight percentage of 10% as binding agent and weight percentage are 10% Super Lithium carbon black (MTI, with a purity of 99.5%) was mixed, and N-methyl-2-pyrrolidone (NMP, Sigma, with a purity of 99.5%) was used as a dispersant to prepare a cathode slurry. The prepared cathode slurry was coated on a circular nickel foam (MTI, purity 99%) with a diameter of 1 cm. After drying in a vacuum oven at 60°C for 5 hours, press the positive electrode sheet under a pressure of 8 MPa to obtain the positive electrode. The M13 phage / sulfur electrode composite material loaded on the positive electrode sheet is about 2 mg / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com