Integrated gasification molten carbonate fuel cell power generating system

A technology of molten carbonate and integral coal gasification, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve problems such as failure to take into account the effective use of heat, battery life reduction, etc., and achieve clean and efficient The effect of utilization and pollutant emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

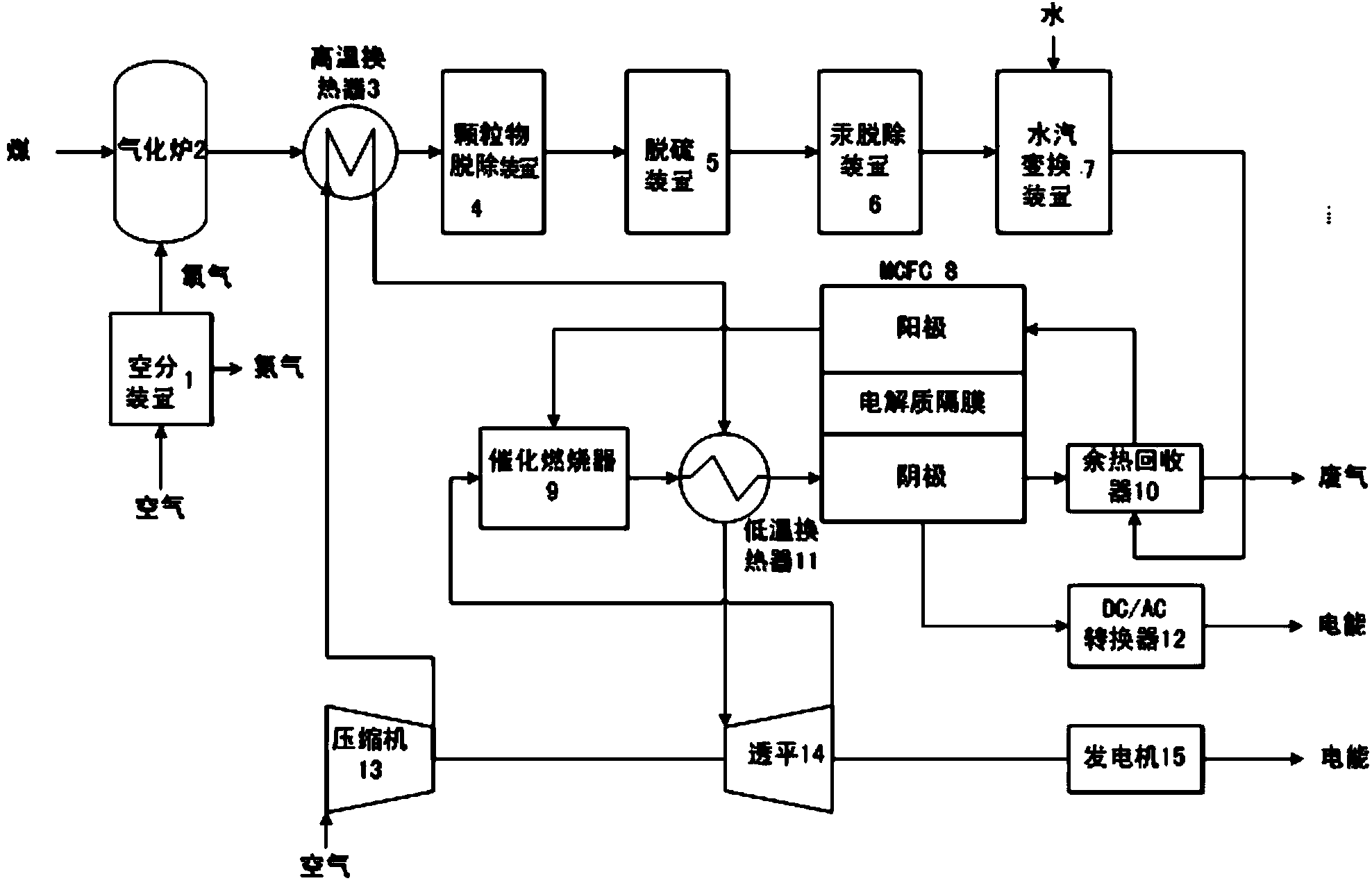

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] With reference to the accompanying drawings, a kind of integrated coal gasification molten carbonate fuel cell power generation system comprises an air separation unit 1, the inlet of the air separation unit 1 is fed with air, and the oxygen outlet of the air separation unit 1 is connected to the oxygen inlet of the gasifier 2, The nitrogen outlet of the air separation unit 1 is connected to the nitrogen storage device, the coal inlet of the gasifier 2 is filled with coal, the high-temperature gas outlet of the gasifier 2 is connected to the high-temperature gas inlet of the high-temperature heat exchanger 3, and the low-temperature gas of the high-temperature heat exchanger 3 The inlet is connected to the outlet of the compressor 13, the inlet of the compressor 13 is fed with air, the high-temperature gas outlet of the high-temperature heat exchanger 3 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com