Rotating wheel non-contact excitation type fluid kinetic energy conversion device

A technology of kinetic energy conversion and rotating wheels, which is applied in the direction of engines, wind power generation, engine components, etc., can solve the problems of complex mechanical structures, short service life, structural fatigue damage, etc., and achieve the effect of flexible installation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

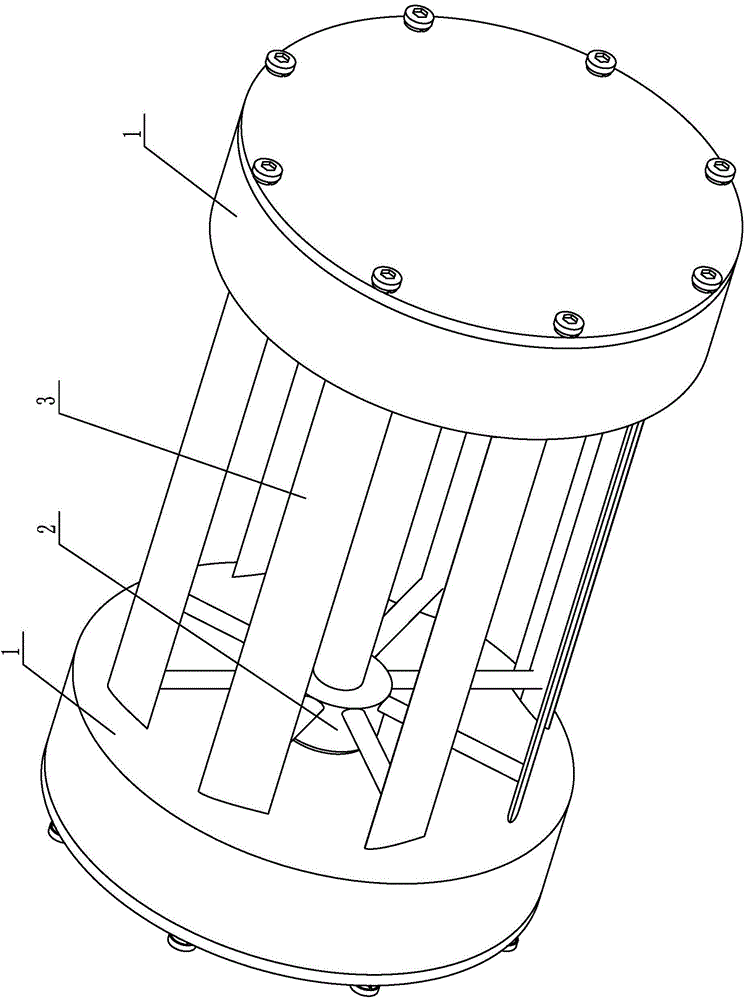

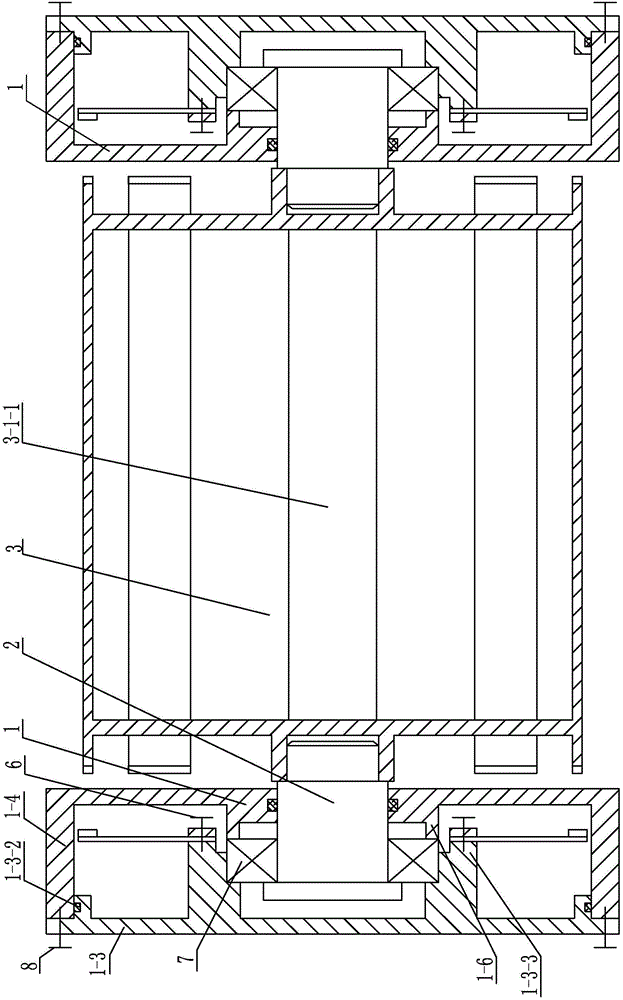

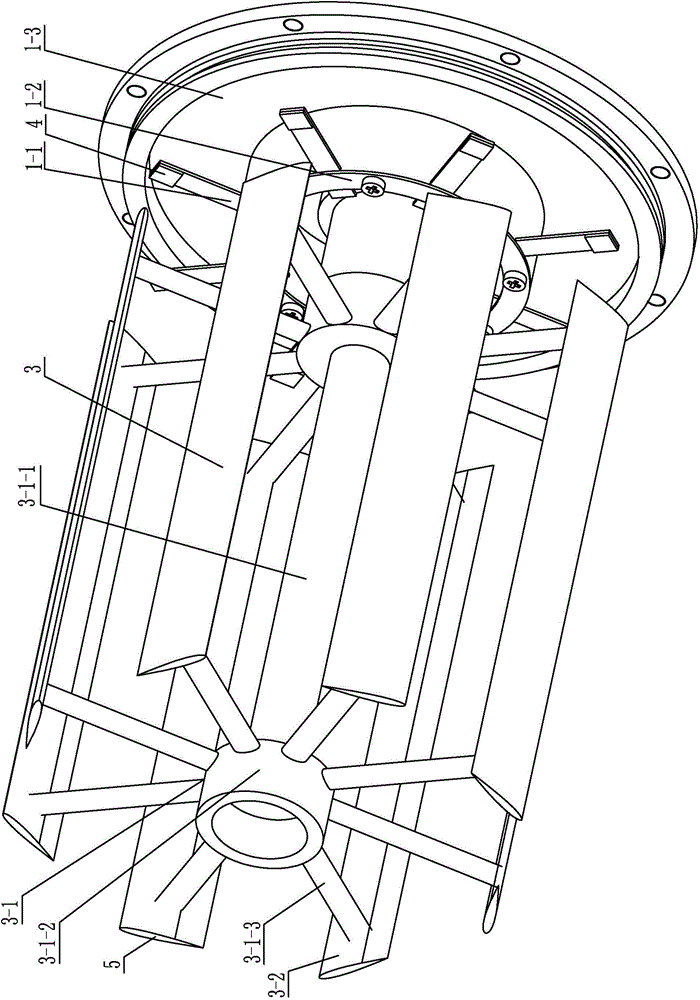

[0018] Specific implementation mode one: combine Figure 1-Figure 8 Explain that the rotating wheel non-contact excitation fluid kinetic energy conversion device of this embodiment includes a rotating wheel 3, two sets of fixed bases 1, two wheel axles 2, 2N excited magnet pieces 4 and 2N excited magnet pieces 5; Where N is a positive integer, and N≥8;

[0019] The rotating wheel 3 includes a support shaft frame 3-1 and N wheel plates 3-2;

[0020] Each fixed base 1 includes a barrel-shaped casing 1-4, a neck flange base 1-3 and N piezoelectric composite cantilever beams 1-1, and the middle part of the bottom of the barrel-shaped casing 1-4 is processed There are through holes 1-5;

[0021] Each piezoelectric composite cantilever beam 1-1 includes a metal elastic plate 1-1-1 and two piezoelectric ceramic sheets 1-1-2, and one end of each metal elastic plate 1-1-1 is installed on a flange with a neck On the end face of the neck 1-3-3 of the base 1-3, the length direction of ...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination Figure 7 and Figure 8 Note that the number of piezoelectric composite cantilever beams 1 - 1 in this embodiment is eight. Such arrangement satisfies the requirement of effective conversion from vibration energy to electric energy. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Specific implementation mode three: combination Figure 8 Note that each metal elastic plate 1-1-1 in this embodiment is a phosphor bronze elastic plate. In this way, the phosphor bronze has good elasticity, wear resistance and fatigue resistance, and is easy to use. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com