Modifier for copper-containing wastes

A technology of waste and modifier, applied in the field of modifier, can solve the problems of human health injury, sending to landfill for disposal, secondary pollution of the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

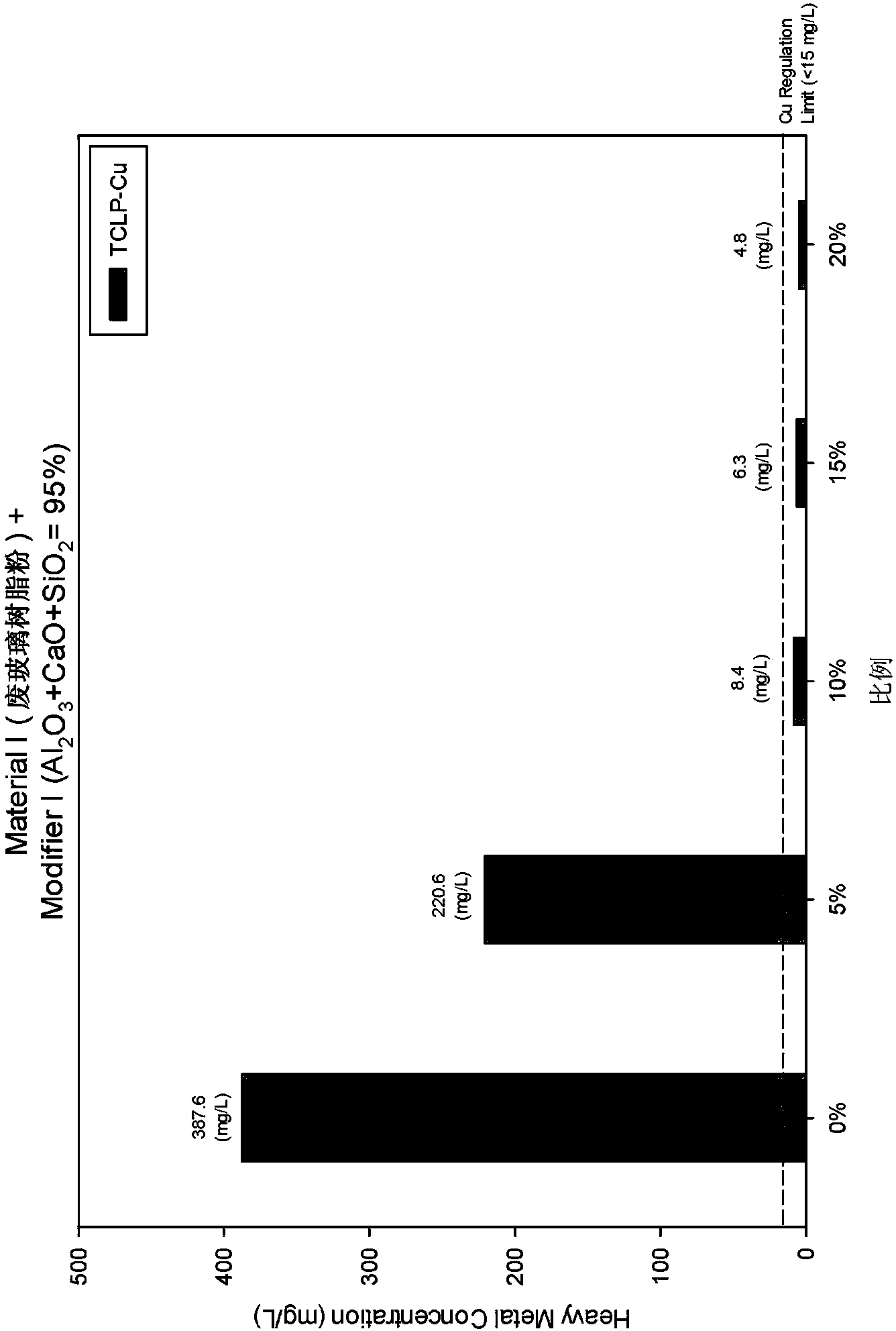

[0020] refer to figure 1 , first of all, the modifier uses silicon oxide, aluminum oxide, calcium oxide and other elements, and the total weight percentage of these elements is 95%, which is added to the waste glass fiber resin powder recycled from printed circuit boards, that is, the following table Types listed:

[0021] Addition amount of modifier Addition amount of waste glass fiber resin powder Copper dissolution rate Not added (known) 100% 387.6 add 5% 95% 220.6 add 10% 90% 8.4 Add 15% 85% 6.3 add 20% 80% 4.8

[0022] The above-mentioned modifier and the waste glass fiber resin powder are mixed according to the above-mentioned different ratios, and 100g after mixing is taken as an example, according to the dissolution procedure of industrial waste toxicity characteristics in Taiwan, China (NI EA R201.14C, heavy metal leached copper content) Carry out the test, learn after the test that the stripping rate of copper tha...

experiment example 2

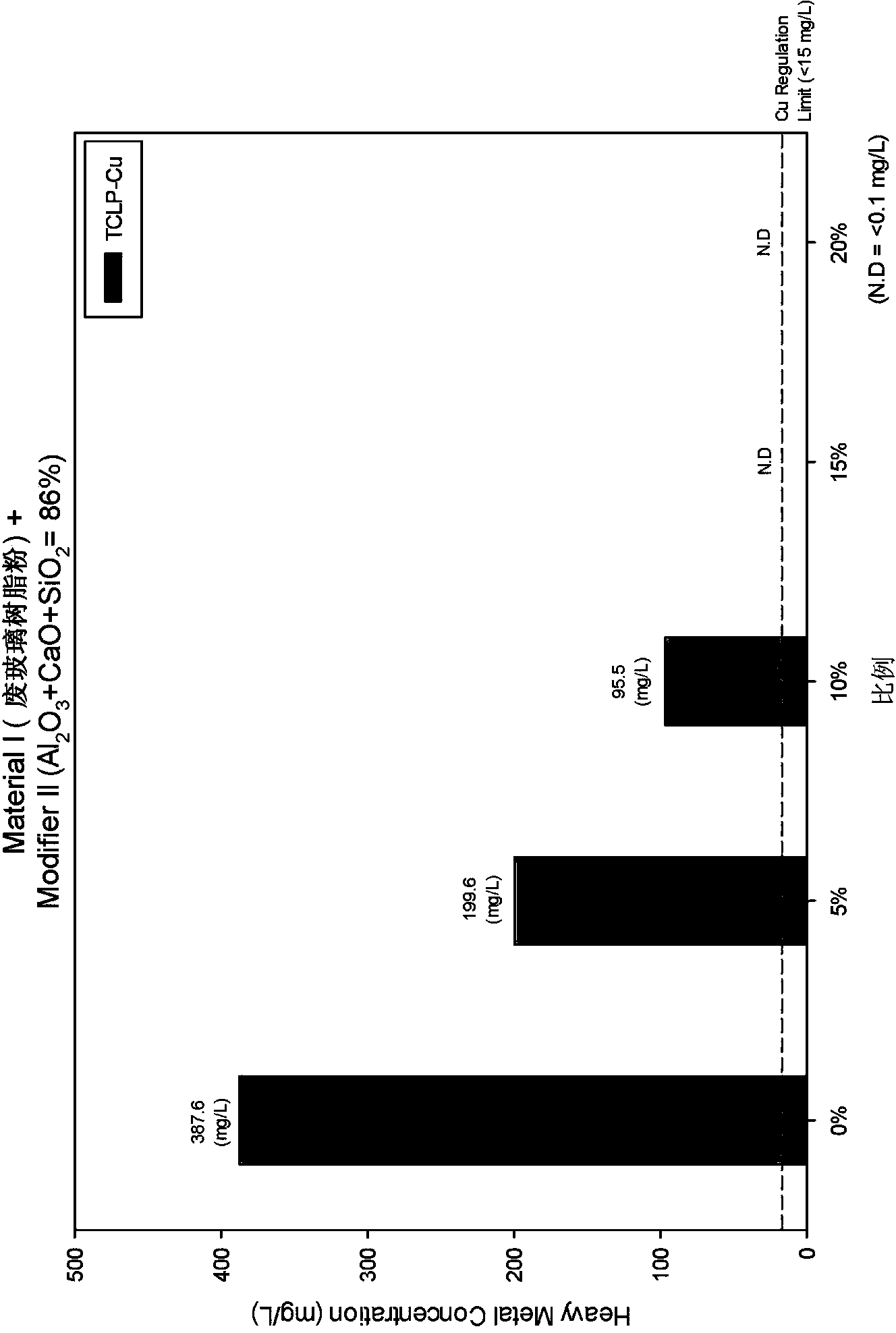

[0024] refer to figure 2 , the modifier uses silicon oxide, aluminum oxide, calcium oxide and other elements, and the total weight percentage of these elements is 86%, which is added to the waste glass fiber resin powder recycled from printed circuit boards, which is listed in the following table Type:

[0025] Addition amount of modifier Addition amount of waste glass fiber resin powder Copper dissolution rate Not added (known) 100% 387.6 add 5% 95% 199.6 add 10% 90% 95.5 Add 15% 85% not detected add 20% 80% not detected

[0026] The above-mentioned modifier and the waste glass fiber resin powder are mixed according to the above-mentioned different ratios, and 100g after mixing is taken as an example, according to the dissolution procedure of industrial waste toxicity characteristics in Taiwan, China (NI EA R201.14C, heavy metal leached copper content) Carried out the test, learned after the test that the stripping rate...

experiment example 3

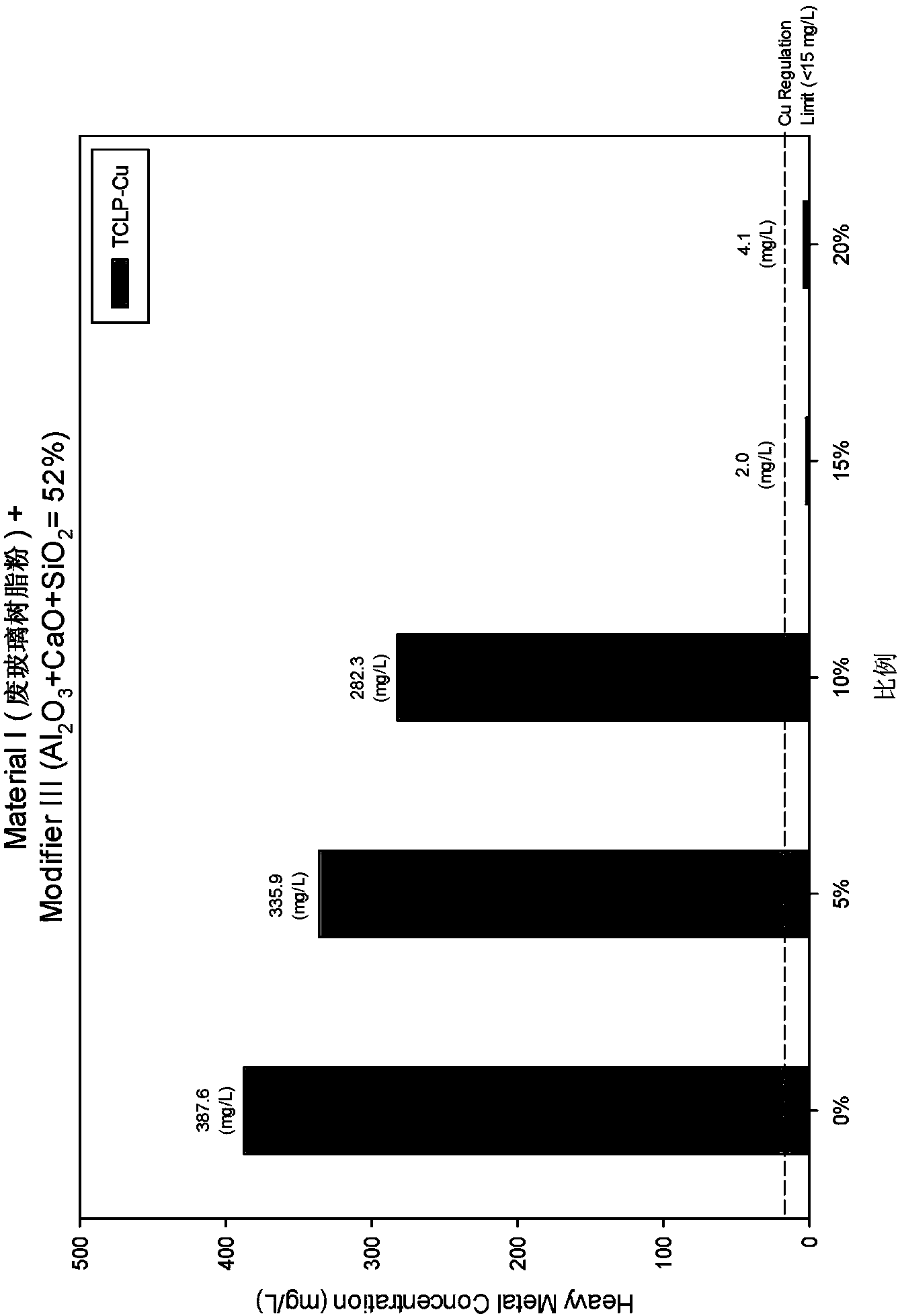

[0028] refer to image 3 , the modifier uses silicon oxide, aluminum oxide, calcium oxide and other elements, and the total weight percentage of these elements is 52%, which is added to the waste glass fiber resin powder recycled from printed circuit boards, which is listed in the following table Type:

[0029] Addition amount of modifier Addition amount of waste glass fiber resin powder Copper dissolution rate Not added (known) 100% 387.6 add 5% 95% 335.9 add 10% 90% 282.3 Add 15% 85% 2.0 add 20% 80% 4.1

[0030] The above-mentioned modifier and the waste glass fiber resin powder are mixed according to the above-mentioned different ratios, and 100g after mixing is taken as an example, according to the dissolution procedure of industrial waste toxicity characteristics in Taiwan, China (NI EA R201.14C, heavy metal leached copper content) Carry out the test, learn after the test that the dissolution rate of copper that can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com