Process for fabricating template pipe-containing cast part in manner of pre-embedding stainless steel pipeline

A preparation type, stainless steel technology, applied in the field of casting, can solve the problems of water pipe displacement, large stress deformation, machining, etc., to achieve the effect of improving service life, eliminating stress deformation, and ensuring shape and position tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

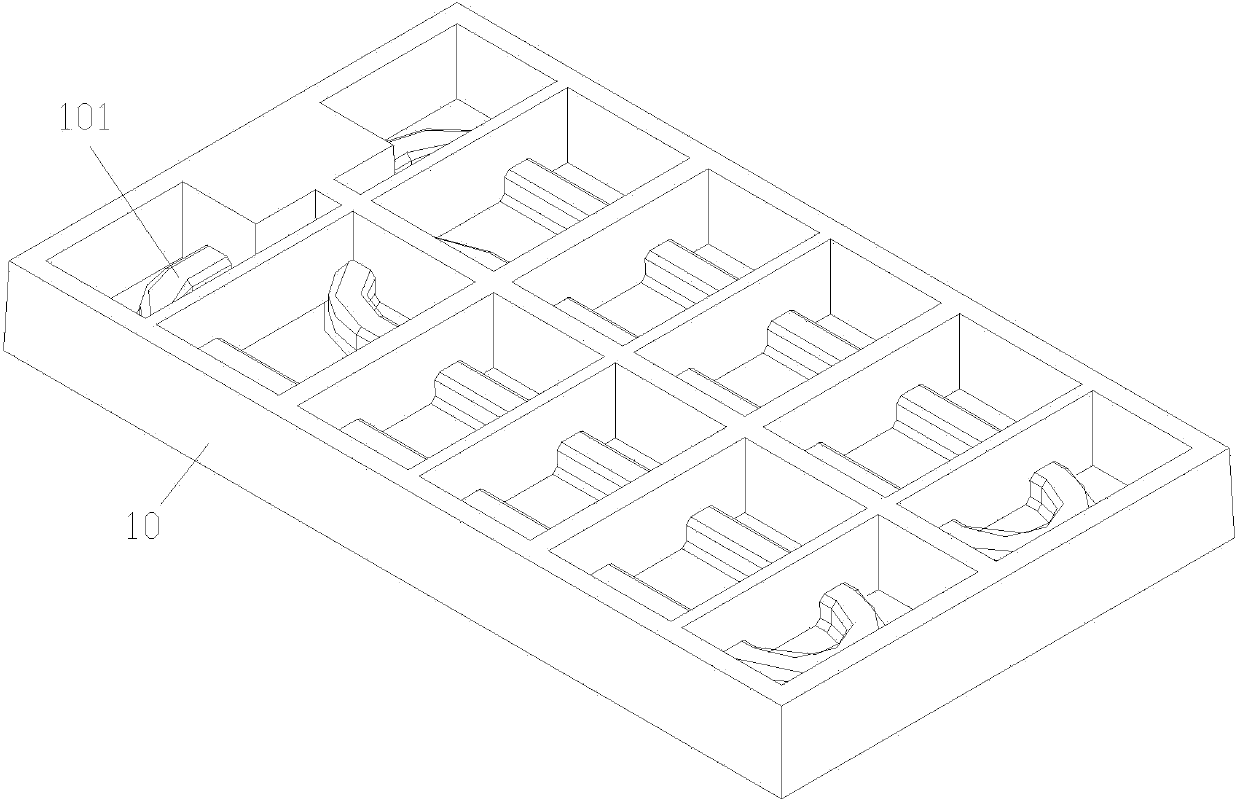

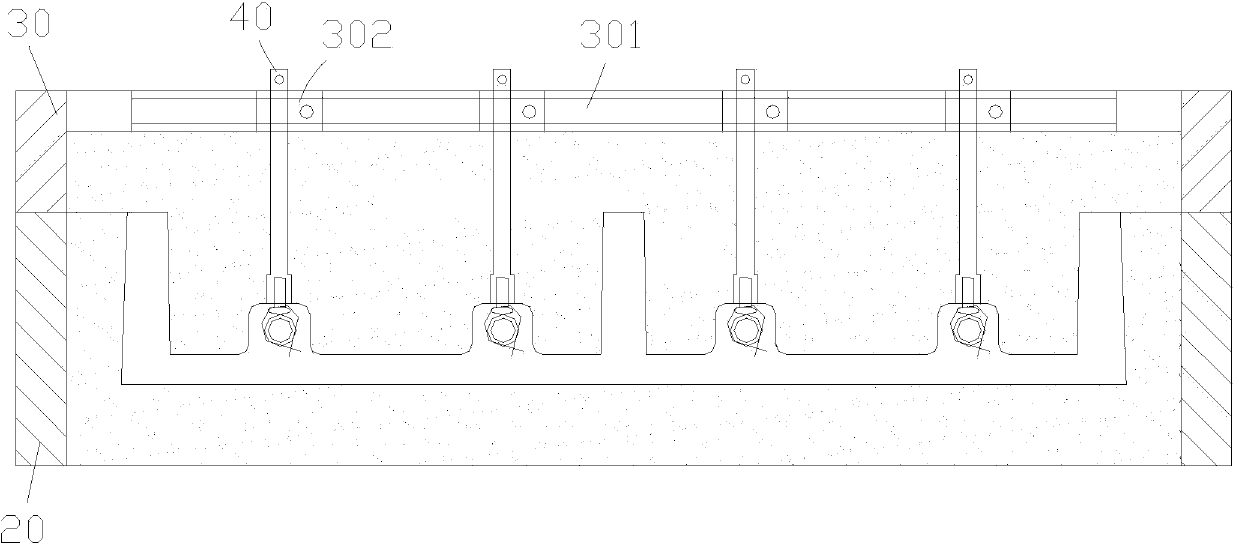

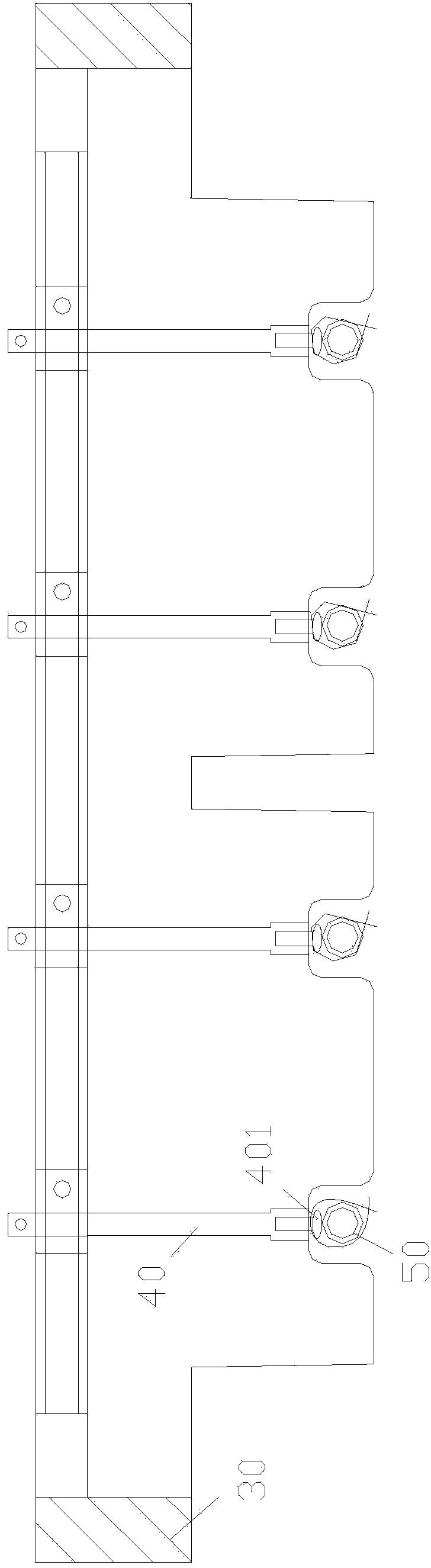

[0028] see Figure 1-3 Shown:

[0029] A process for preparing molded plate-type castings containing pipes by pre-embedding stainless steel pipes, comprising the following method steps:

[0030] 1) The wooden mold 10 is manufactured according to the drawings, and the water pipe groove 101 is manufactured in the inner cavity of the wooden mold 10 according to the technical requirements and process requirements, and the cross-sectional size of the water pipe groove 101 is 15*30mm;

[0031] 2) Select a suitable sand box according to the wooden mold 10, and face the water pipe groove 10 upwards, and make the lower box 20 sand molds according to the process;

[0032] 3) After the sand mold of the lower box 20 is completed, select a suitable special...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com