Method for reducing magnesium-based hydride hydrogen-release temperature by utilizing solid-solution doping of transition metal

A magnesium-based hydride, transition metal technology, applied in the direction of transition element hydride, alkali metal/alkaline earth metal/beryllium/magnesium hydride, chemical instruments and methods, etc., can solve problems such as low solid solubility, and achieve the preparation process. Simple, low hydrogen release temperature, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

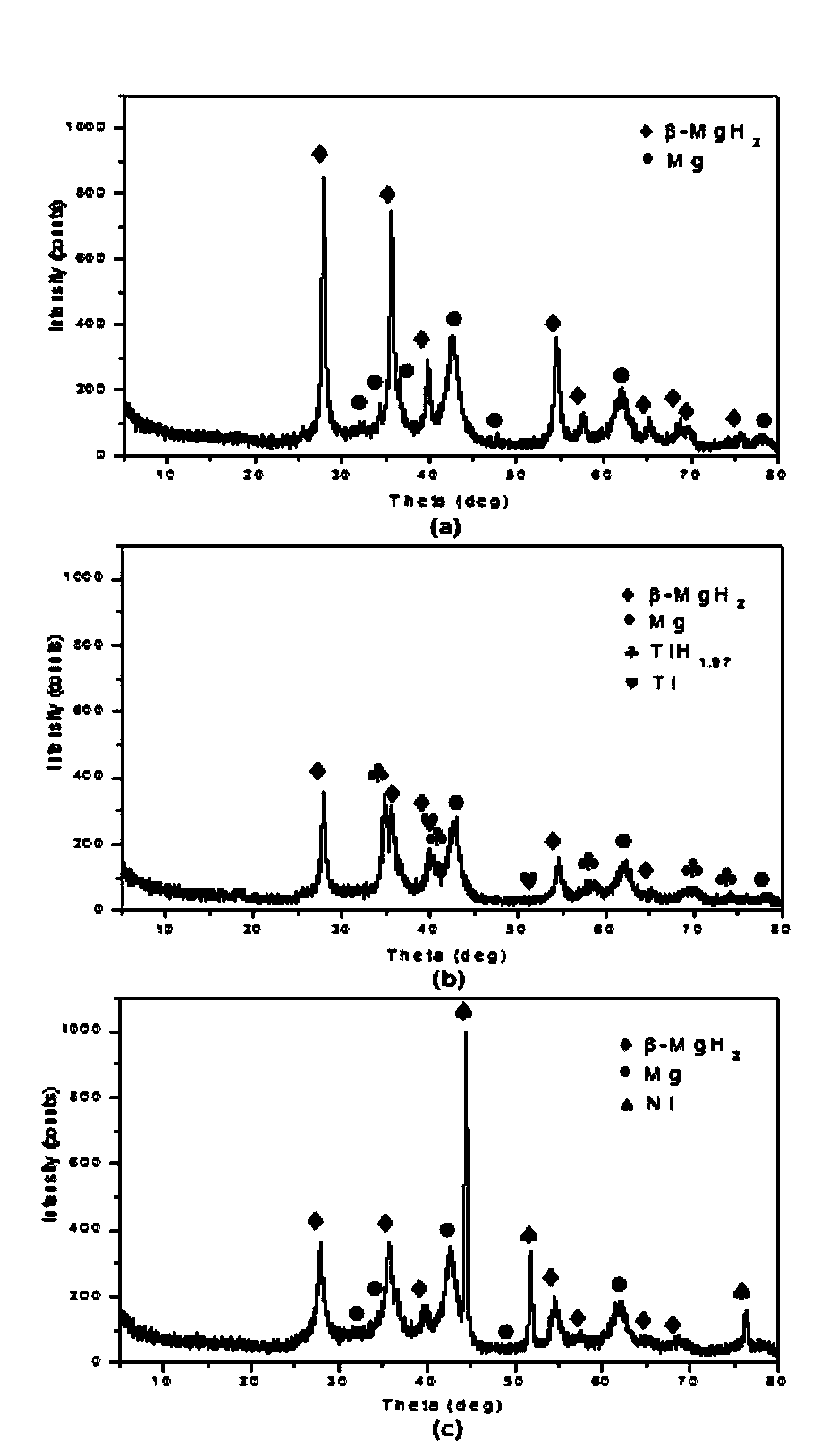

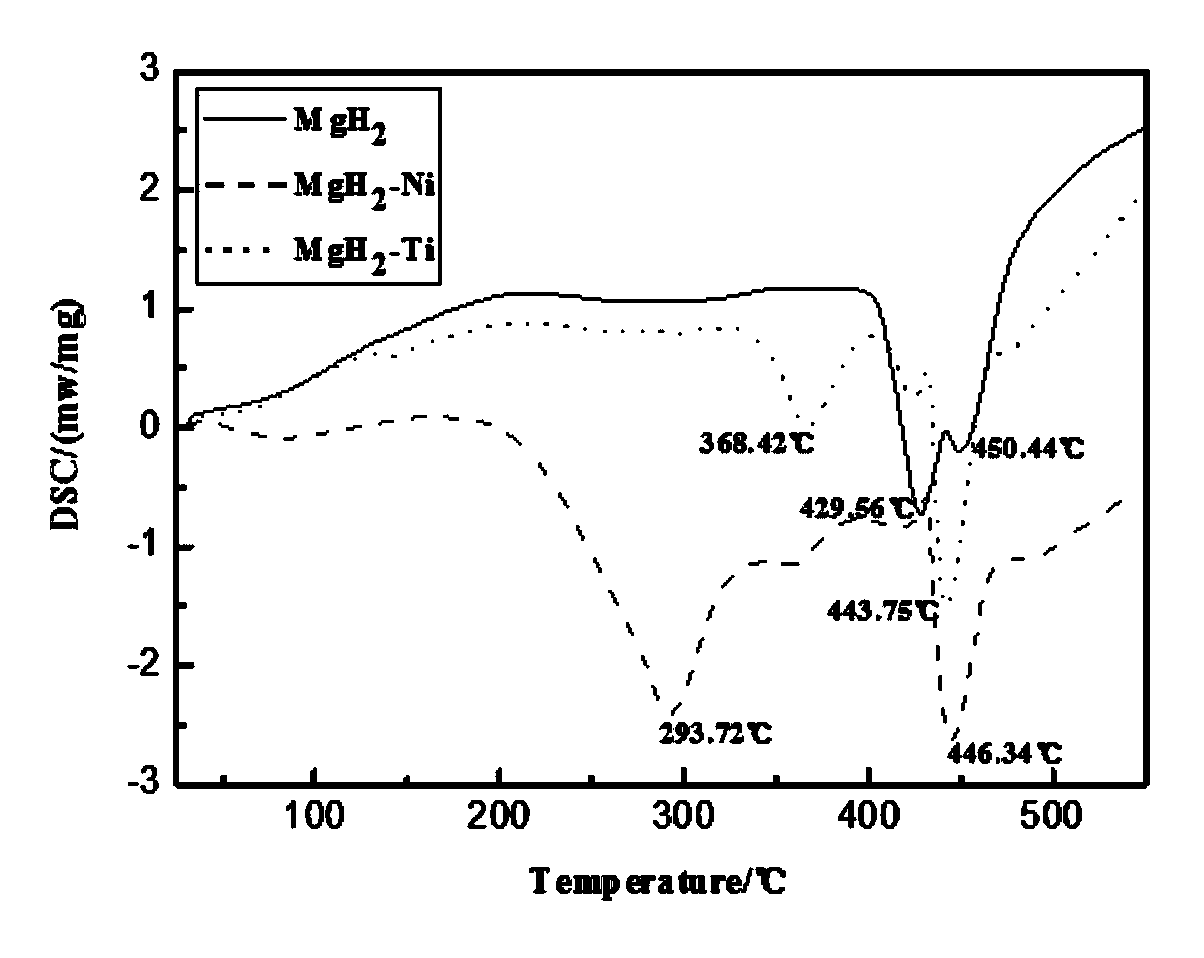

[0029] The raw material is commercially available magnesium hydride powder (MgH 2 , purity 99.8wt.%), transition metal powder titanium (Ti, purity 99.9wt.%); the two are mixed evenly with a mass ratio of 9:1, and 3g of the mixed raw material is put into a ball mill tank, and the ball and the mixed raw material The ratio is 30:1, the ball milling time is 6 hours, and the ball milling speed is 120rpm. During the ball milling process, in order to prevent the temperature in the tank from being too high, stop for 5 minutes every 55 minutes of ball milling. MgH obtained after ball milling 2 -10wt.%Ti composite system has a particle size of several hundred nanometers, compared to pure MgH under the same ball milling conditions 2 system (see figure 1 (a)), the particle size is obviously fine and evenly distributed (see figure 1 (b)); The ball milled product is made of β-MgH 2 、TiH 1.97 , Mg, Ti multiphase composition (see figure 2 (b)); Calculate the β-MgH in the composit...

Embodiment 2

[0033] The raw material is commercially available magnesium hydride powder (MgH 2 , purity 99.8wt.%), transition metal powder nickel (Ni, purity 99.9wt.%); the two are mixed evenly with a mass ratio of 9:1, and 3g of mixed raw materials are put into a ball mill tank. Other process parameters and implementation Example 1 is the same. MgH obtained after ball milling 2 The particle size of -10wt.%Ni composite system has reached hundreds of nanometers (see figure 1 (c)); The ball milled product is made of β-MgH 2 , Mg, Ni multiphase composition (see figure 2 (c)); Calculate the β-MgH in the composite system by refining the XRD spectrum 2 The lattice constant (see Table 1), and pure MgH under the same ball milling conditions 2 Compared with the system, the β-MgH in the composite system 2 The lattice constant of the phase increases, indicating that some Ni atoms are solid-dissolved into β-MgH 2 In the matrix, resulting in its lattice expansion; DSC analysis results sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com