Method for preparing dahurian larch-based resin carbon aerogel microspheres

A technology of carbon airgel and larch, which is applied in the direction of climate sustainability, sustainable manufacturing/processing, chemical industry, etc., can solve the problems of low production efficiency and long time consumption, and achieve high utilization rate and low raw material cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

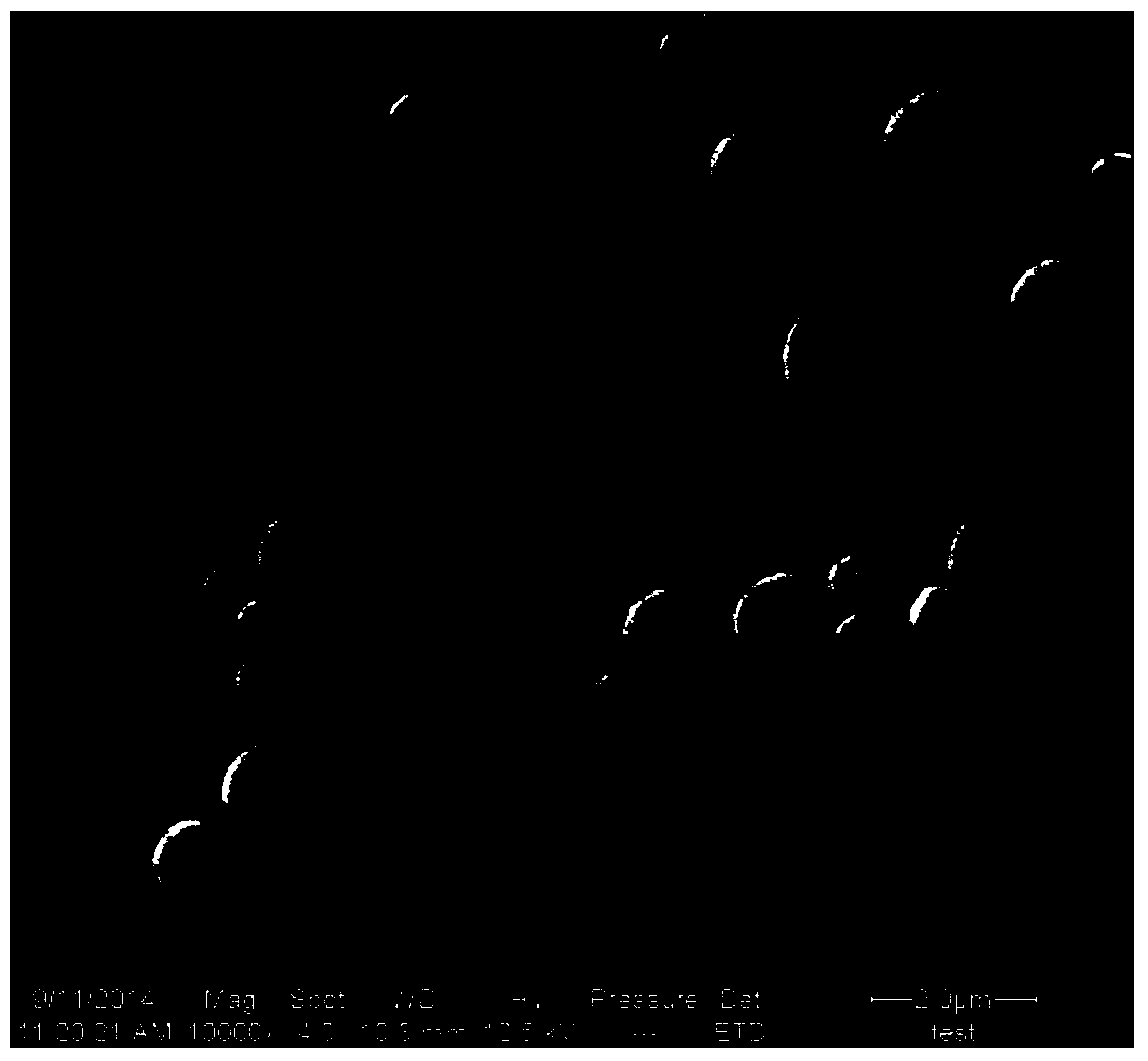

Image

Examples

Embodiment 1

[0028] Take 10.0g of larch sawdust, 30.0g of phenol, 1.0mL of concentrated sulfuric acid (98%), and 2.0mL of phosphoric acid (85%) at 110°C for 2 hours of reflux reaction. After cooling to room temperature, add 80mL of methanol, stir well, filter and wash, and collect filtrate. Neutralize the filtrate to neutral with sodium hydroxide, filter to remove insoluble matter such as salt, collect the filtrate and distill methanol under reduced pressure at 40°C to obtain brown larch liquefaction. Add 90mL formaldehyde solution (37%), 3.0g NaOH, 10.0g P123 to the flask successively, react at 40°C for 20h, then add 10mL concentrated hydrochloric acid, adjust the pH to 0.5, continue the reaction for 8h, cool to room temperature after the reaction, and wash Dry in an oven at 100°C to obtain a larch-based resin interphase.

[0029] Using the self-developed sprayer combined with the calcination furnace, through the spray pyrolysis method, it can be formed into light larch liquefied microsp...

Embodiment 2

[0031] Take 10.0g of larch sawdust, 30.0g of phenol, 2.0mL of concentrated sulfuric acid (98%), and 2.0mL of phosphoric acid (85%) at 120°C for 2 hours of reflux reaction. After cooling to room temperature, add 100mL of methanol, stir well, filter and wash, and collect filtrate. Neutralize the filtrate to neutral with sodium hydroxide, filter to remove insoluble matter such as salt, collect the filtrate and distill methanol under reduced pressure at 40°C to obtain brown larch liquefaction. Add 90mL formaldehyde solution (37%), 3.0g NaOH, 10.0g P123 to the flask successively, react at 40°C for 20h, then add 10mL concentrated hydrochloric acid, adjust the pH to 0.5, continue the reaction for 8h, cool to room temperature after the reaction, and wash Dry in an oven at 100°C to obtain a larch-based resin interphase.

[0032]Using the self-developed sprayer combined with the calcination furnace, through the spray pyrolysis method, it can be formed into light larch liquefied microsp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com