A film-forming agent for air-conditioning heat sinks and a preparation method thereof

A film-forming agent and cooling fin technology, applied in the field of daily chemicals, can solve the problems of reducing the heating and cooling efficiency of air conditioners, shortening the service life of air conditioners, and increasing energy consumption, so as to reduce energy consumption, reduce peculiar smell, and reduce adsorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

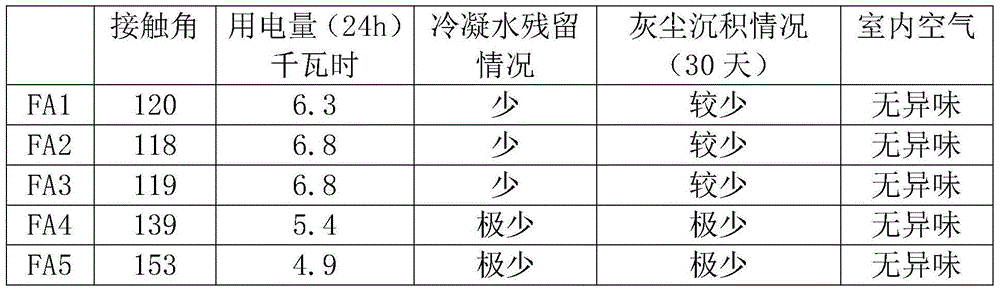

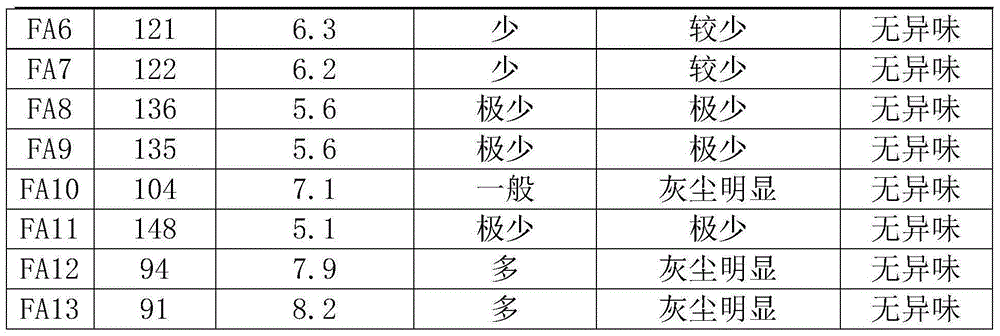

Examples

Embodiment 1

[0019] A film-forming agent for air-conditioning heat sinks provided in this embodiment is composed of the following substances: 47g of 95% ethanol, 1g of diethylhexyl carbonate, and 1g of diquaternized polydimethylsiloxane.

[0020] The above-mentioned preparation method for the film-forming agent of air-conditioning fins:

[0021] At room temperature (15-30°C), add 47g of water to the beaker, then continue to add 1g of diethylhexyl carbonate and 1g of diquaternized polydimethylsiloxane to the beaker, stir well (stir for more than 30s) , to obtain a film-forming agent, denoted as FA1.

[0022] Pack the film-forming agent into a storage bottle for later use.

[0023] When in use, spray the film-forming agent on the cleaned air-conditioning heat sink to completely wet the air-conditioning heat sink.

Embodiment 2

[0025] A film-forming agent for air-conditioning heat sinks provided in this embodiment is composed of the following substances: 47g 95% ethanol, 1g diethylhexyl carbonate, 1g diquaternized polydimethylsiloxane, 0.1g p-chlorine m-xylenol, 0.9g lauryl polyoxyethylene ether (AEO9), 0.5g essence.

[0026] The above-mentioned preparation method for the film-forming agent of air-conditioning fins:

[0027] At room temperature (15-30°C), add 47g of 95% ethanol to the beaker, then add 1g of diethylhexyl carbonate and 1g of diquaternized polydimethylsiloxane, and stir evenly (stir for more than 30s). Then continue to add 0.1g p-chloro-m-xylenol, 0.9g AEO9 and 0.5g essence in the beaker, and stir evenly (stir more than 30s), make film-forming agent, denote as FA2.

[0028] Pack the film-forming agent into a storage bottle for later use.

[0029] When in use, spray the film-forming agent on the heat sink of the air conditioner to completely wet the heat sink of the air conditioner.

Embodiment 3

[0031] A film-forming agent for air-conditioning heat sinks provided in this embodiment is composed of the following substances: 47g 95% ethanol, 1g diethylhexyl carbonate, 1g diquaternized polydimethylsiloxane, 0.1g p-chlorine m-xylenol, 0.9g AEO9, 50ml nitrogen.

[0032] The above-mentioned preparation method for the film-forming agent of air-conditioning fins:

[0033] At room temperature (15-30°C), add 47g of 95% ethanol to the beaker, then add 1g of diethylhexyl carbonate and 1g of diquaternized polydimethylsiloxane, and stir evenly (stir for more than 30s). Then continue to add 0.1g of p-chloro-m-xylenol and 0.9g of AEO9 into the beaker, and stir evenly (stirring for more than 30s) to obtain a stock solution.

[0034] Pour the stock solution into a 100ml tinplate aerosol can, fill the tinplate aerosol can with 50ml of nitrogen, cover the nozzle, and prepare the film-forming agent stored in the tinplate aerosol can. The obtained film-forming agent is denoted as FA3.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com