A kind of digestion device and its application method for the determination of total nitrogen in pond sediment

A sediment and digestion technology, applied in the field of fishery ecological environment research of aquaculture discipline, can solve the problems of air pollution, difficulty of digestion device, inability to absorb poisonous gas, etc., and achieve the effect of easy storage, easy assembly and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

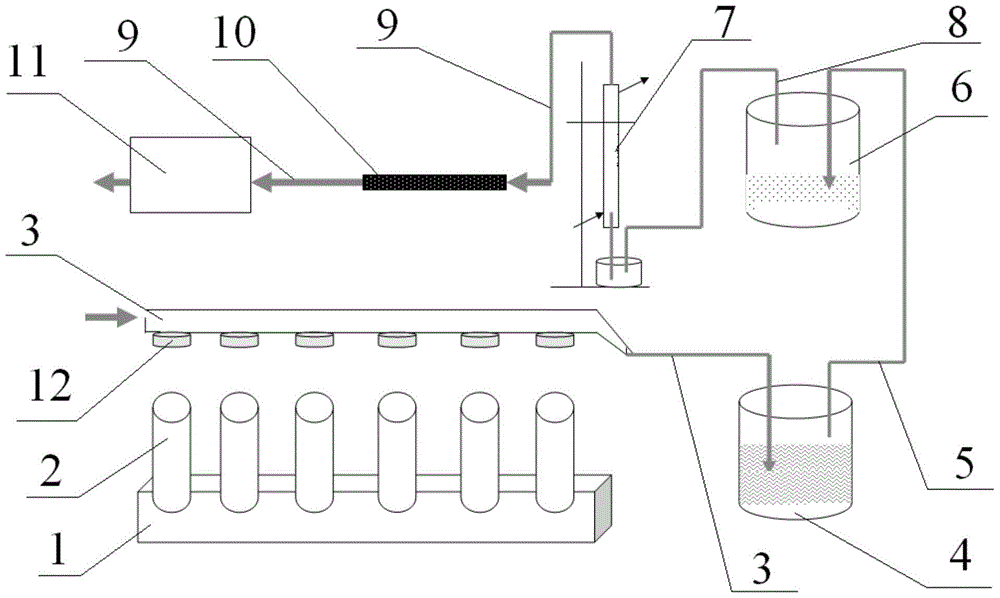

[0023] Such as figure 1 Shown, a kind of digestion device that is used for pond sediment total nitrogen determination comprises electric furnace 1, digestion pipe 2, first container 4, second container 6, condenser 7, adsorption pipe 10 and vacuum pump 11;

[0024] The electric furnace 1 is provided with several digesting pipes 2, and the several digesting pipes 2 are communicated through the air intake pipe 3 and then lead to below the liquid level of the first container 4; the first container 4 and the second container 6 pass through the first container 4 A gas outlet pipe 5 is connected, and the first gas outlet pipe 5 leads to the bottom of the second container 6;

[0025] The second container 6 is connected to the condenser 7 through a second outlet pipe 8; the second container 6 is connected to an adsorption pipe 10 and a vacuum pump 11 through a pipeline 9 in sequence.

[0026] The digestion pipes 2 are provided with corresponding digestion pipe covers 12, and the dige...

Embodiment 2

[0032] The method of using the digestion device for the determination of total nitrogen in pond sediments, the steps are as follows:

[0033] (1) Pretreatment: freeze-dry the sediment to be digested at -40°C for 10 hours, and then pass through a 90-mesh sieve to obtain a sediment sample;

[0034] (2) Adding samples: Add 0.4g of the sediment sample obtained in step (1) to each digestion tube 2, then add 1.8g of mixed oxidant, mix well, and then add 4mL of concentrated sulfuric acid with a mass concentration of 98%;

[0035] (3) Digestion: Close the digestion tube cover 12 and the digestion tube 2 tightly, turn on the electric furnace below, heat to 150-200°C for 1.5 hours, and cook until the liquid in the tube is clear and transparent;

[0036] (4) Tail gas treatment: turn on the vacuum pump 11, and the pumping pressure is 10MPa. The tail gas generated by the reaction of the digestion pipe 2 first enters the sodium hydroxide solution in the first container 4 through the intake ...

Embodiment 3

[0039] The method of using the digestion device for the determination of total nitrogen in pond sediments, the steps are as follows:

[0040] (1) Pre-treatment: The sediment to be digested was freeze-dried at -80°C for 5 hours, and then passed through a 110-mesh sieve to obtain a sediment sample;

[0041] (2) Adding samples: Add 0.6g of the sediment sample obtained in step (1) to each digestion tube 2, then add 2.2g of mixed oxidant, mix well, and then add 6mL of concentrated sulfuric acid with a mass concentration of 95%;

[0042] (3) Digestion: Close the digestion tube cover 12 and the digestion tube 2 tightly, turn on the lower electric furnace, heat to 200-300°C for 0.5h, and digest until the liquid in the tube is clear and transparent;

[0043] (4) Tail gas treatment: turn on the vacuum pump 11, and the pumping pressure is 30 MPa. The tail gas generated by the reaction of the digestion pipe 2 first enters the sodium hydroxide solution in the first container 4 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com