Photocatalysis and microorganism composite anode fuel battery system

A fuel cell system and composite anode technology, applied in biochemical fuel cells, fuel cells, battery electrodes, etc., can solve the problems of low output power density, difficult recycling of electrical energy, and high cathode cost, and achieve increased power density and cathode potential. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

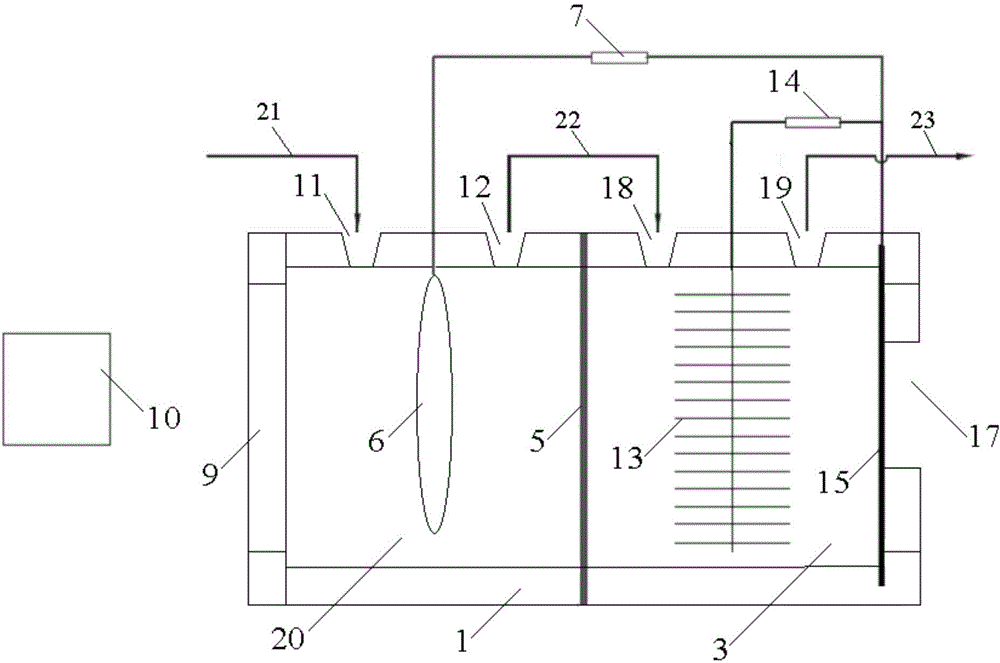

[0019] Specific Embodiment 1: This embodiment is a photocatalytic and microbial composite anode fuel cell system including a box body 1, a microbial anode chamber 3, an ion exchange membrane 5, a photocatalytic anode 6, a first resistor 7, a quartz glass window 9, Light source 10, photoanode chamber water inlet 11, photoanode chamber water outlet 12, microbial anode 13, second resistor 14, cathode 15, opening 17, microbial anode chamber water inlet 18, microbial fuel cell water outlet 19, photoanode chamber 20, water inlet pipe 21, conduit 22 and water outlet pipe 23;

[0020] One side of the box 1 is inlaid with a quartz glass window 9, the other side of the box 1 is provided with an opening 17, and the upper surface of the box 1 is provided with a photoanode chamber water inlet 11, a photoanode Chamber water outlet 12, microbial anode chamber water inlet 18 and microbial fuel cell water outlet 19; water inlet pipe 21 communicates with photoanode chamber water inlet 11, and p...

specific Embodiment approach 2

[0027] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the photocatalytic anode 6 is a semiconductor material attached to the conductive substrate; the semiconductor material is titanium dioxide, ZnO, WO 3 or MoS 2 . Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the microbial anode 13 is a microbial anode 13, and the microbial anode 13 is an electrochemically active biofilm attached to a carrier; the carrier is Carbon paper, carbon cloth, carbon fiber brush, carbon felt, glassy carbon, carbon nanotubes, graphite or graphene. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com