Self-propelled double row carrot combine harvester

A technology for combine harvesters and carrots, which is applied to digging harvesters, harvesters, and topping machines, etc., which can solve problems such as high maintenance costs, low work efficiency, and differences in planting and agronomy, so as to improve the degree of mechanization and improve operating efficiency , the effect of reducing the fruit drop rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

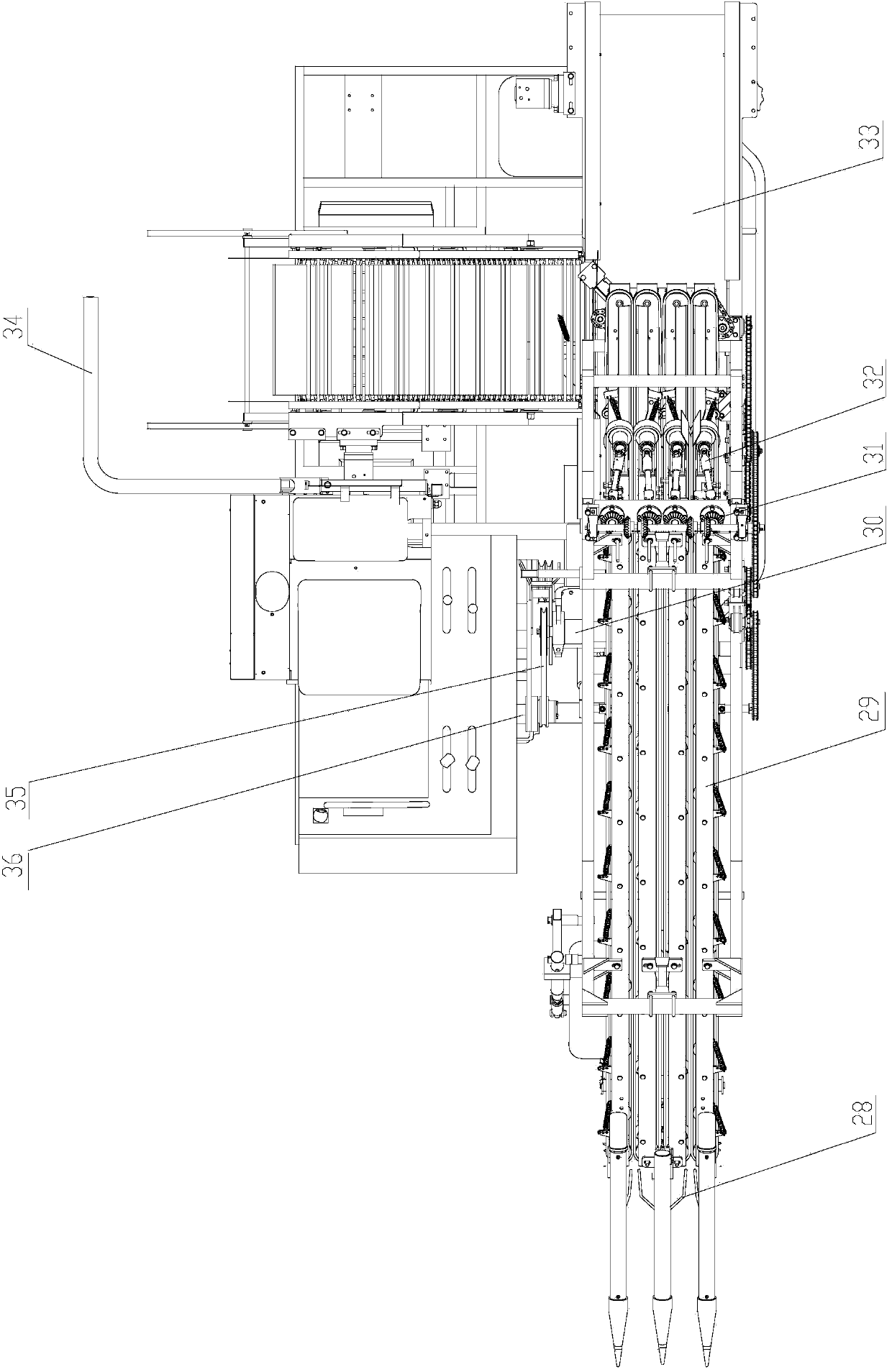

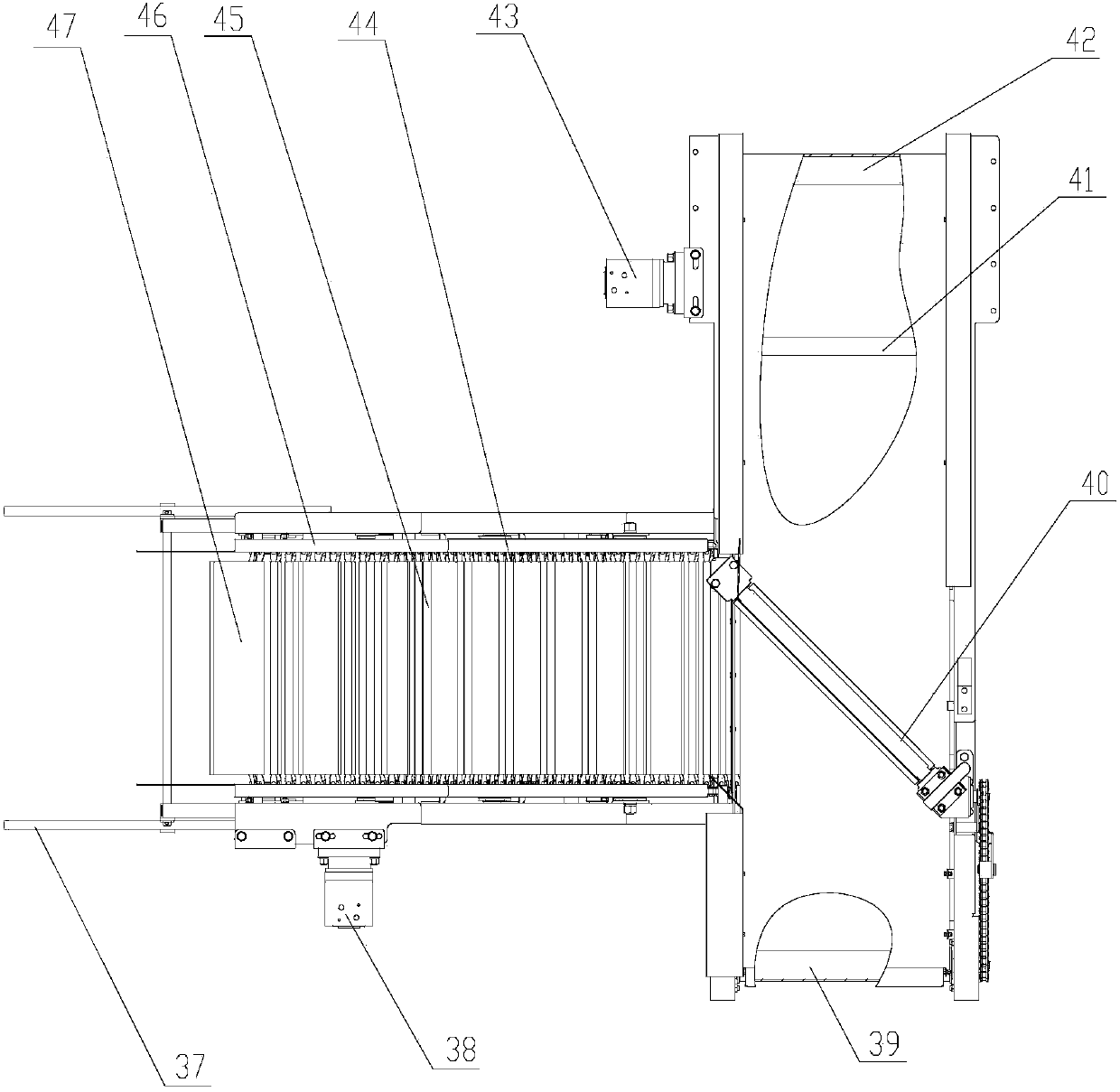

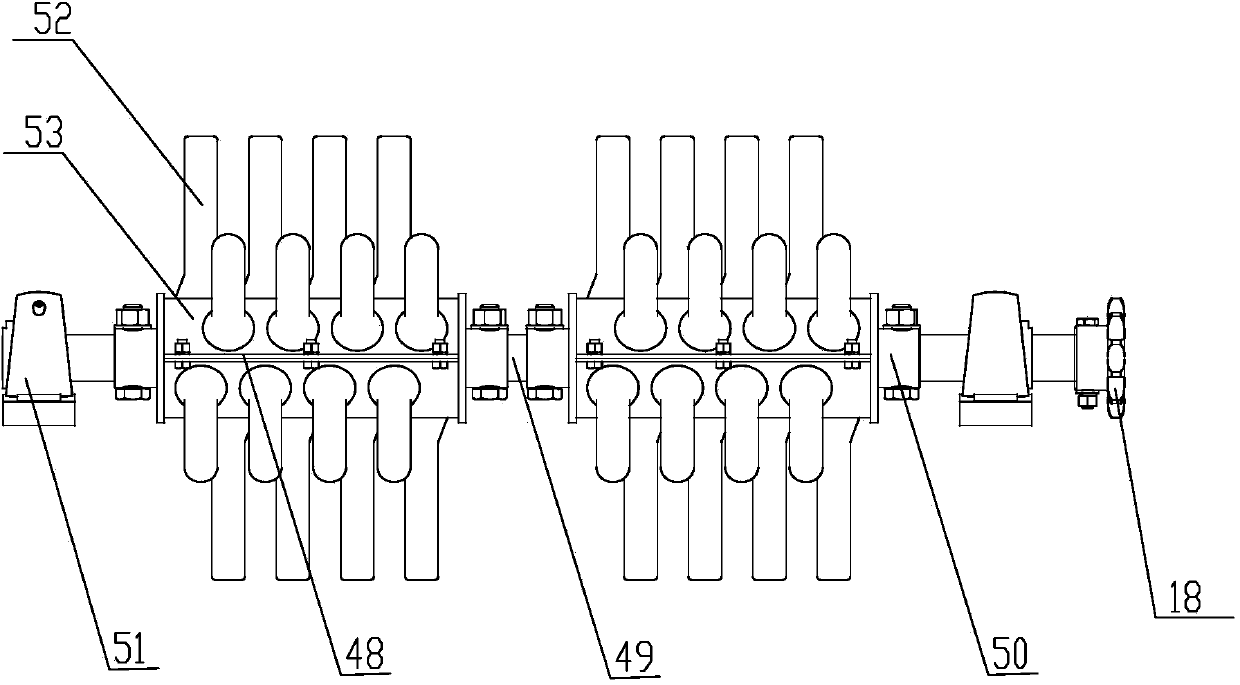

[0035] Self-propelled double-row carrot combine harvester comprises crawler chassis 8, hydraulic system 7 and frame, and said frame comprises front frame 5 and rear frame 9, and front frame 5 is installed on the power of crawler chassis 8 Output shaft 36 one side front ends, rear frame 9 are fixed on the crawler chassis 8. The front frame is provided with a depth-limiting wheel 2, an excavation device, a grain feeding device, an oblique clamping and conveying device, a soil removing device and a seedling cutting device, and the rear frame is provided with a horizontal belt conveying device and a lifting device. Fruit collecting device. The depth-limiting wheel 2 and the excavating device are arranged at the bottom of the front end of the front frame 5, the oblique clamping and conveying device is obliquely arranged above the excavating device, and the helping grain introduction device is arranged at the bottom of the oblique clamping and conveying device. At the front end, th...

Embodiment 2

[0044] The difference from Example 1 is that the length of the soil removal roller teeth is 90 mm, and the diameter of the soil removal roller teeth is 16 mm. The cross section of the tooth mounting plate 53 is circular. 8 rows of soil roller teeth are arranged longitudinally on the roller tooth mounting plate 53 .

Embodiment 3

[0046]The difference from Example 1 is that the length of the soil removal roller teeth is 100 mm, and the diameter of the soil removal roller teeth is 14 mm. The cross section of the tooth mounting plate 53 is a regular octagon. 8 rows of soil roller teeth are arranged longitudinally on the roller tooth mounting plate 53 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com