Environment-friendly expanded feed for Litopenaeus vannamei and preparation method thereof

A technology of extruded feed and vanabine, applied in animal feed, animal feed, application and other directions, can solve problems such as water pollution, and achieve the effects of reducing ammonia nitrogen emissions, excellent stability, and improving feed utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

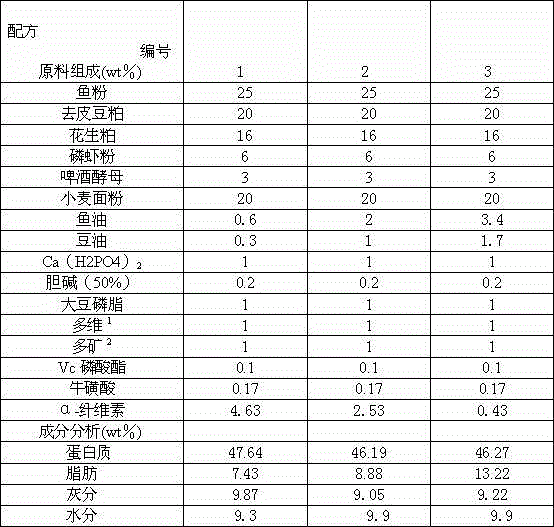

[0025] According to formula 1 shown in Table 1, extruded pellet feed and ring die pellet feed were prepared, and 0.37 g of Litopenaeus vannamei was fed for 56 days at a low temperature of 13-27°C. The feed coefficient of the extruded feed group was 0.95, and the specific growth rate (SGR , %d -1 ) 3.67, growth rate 690.7%, survival rate 83.6%, ring die pellet feed group feed coefficient 1.51, specific growth rate (SGR, %d -1 ) 2.97, the growth rate was 471.7%, and the survival rate was 78.8%. All parameters of extruded feed were higher than ring die pellet feed.

[0026] The preparation method of extruded pellet feed is:

[0027] S1. Weigh the raw materials in said parts by weight, stir and mix all the raw materials separately, pulverize them twice, and mix 100 % Pass through a 60-mesh sieve, mix and stir evenly, add water and fat source raw materials while stirring, and make feed base material.

[0028] S2. Input the above-mentioned feed base material into the biaxial extr...

Embodiment 2

[0031] According to formula 2 shown in Table 1, extruded pellet feed and ring die pellet feed were prepared, and 0.37 g of Litopenaeus vannamei was fed for 56 days at a low temperature of 13-27°C. The feed coefficient of the extruded feed group was 1.12, and the specific growth rate (SGR , %d -1 ) 3.60, growth rate 690.2%, survival rate 70.0%, ring die pellet feed group feed coefficient 1.62, specific growth rate (SGR, %d -1 ) 3.02, the growth rate was 473.5%, and the survival rate was 68.3%. All parameters of extruded feed were higher than ring die pellet feed.

[0032] The preparation method of the expanded pellet feed and the ring die pellet feed is the same as in Example 1.

Embodiment 3

[0034] According to formula 3 shown in Table 1, extruded pellet feed and ring die pellet feed were prepared, and 0.37 g of Litopenaeus vannamei were fed for 56 days at a low temperature of 13-27°C. The feed coefficient of the extruded feed group was 1.4, and the specific growth rate (SGR , %d -1) 3.11, growth rate 523.3%, survival rate 71.7%, ring die pellet feed group feed coefficient 1.75, specific growth rate (SGR, %d -1 ) 2.92, the growth rate was 427.0%, and the survival rate was 67.8%. All parameters of extruded feed were slightly higher than ring die pellet feed.

[0035] The preparation method of the expanded pellet feed and the ring die pellet feed is the same as in Example 1.

[0036] Specific growth rate SGR (% d -1 )=100×(ln final average weight-ln initial average weight) / experimental days

[0037] Weight gain rate WG(%)=(final average weight-initial average weight)×100 / initial average weight

[0038] Survival rate SR (%) = number of remaining shrimp tails at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com