Preparation method of zinc phthalocyanine-pyrene-covalent organic frame/single wall carbon nanotube composite

A single-walled carbon nanotube and covalent organic framework technology, applied in the field of zinc phthalocyanine-pyrene-covalent organic framework/single-walled carbon nanotube composites, can solve the problem of high cost, high equipment requirements, single product, etc. problem, to achieve the effect of simple and high chemical inertness of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

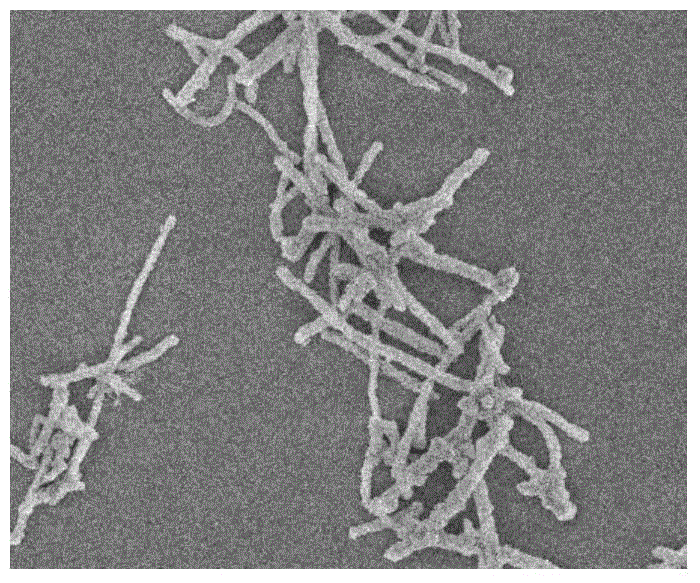

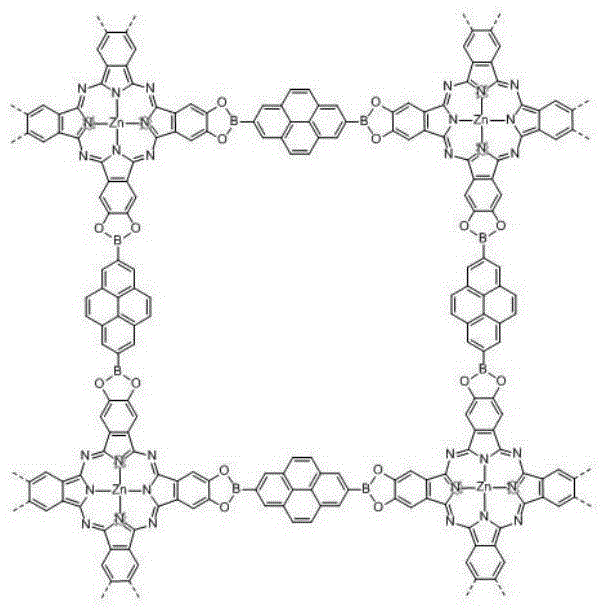

[0025] The preparation method of the zinc phthalocyanine-pyrene-covalent organic framework / single-walled carbon nanotube composite provided in this example is as follows:

[0026] Step 1, get 7.1mg of zinc octahydroxyphthalocyanine, 5.8mg of 2,7-pyrene diboronic acid, 5mg of single-walled carbon nanotubes, add 1ml of dimethylacetamide (DMAc) and 1ml of o-dichlorobenzene ( o-DCB) solvent, put into a heat-resistant glass reaction tube of 10ml, and ultrasonically disperse for 10 minutes to form suspension A;

[0027] Step 2: Suspension A was subjected to liquid nitrogen freezing-vacuumizing-degassing steps three times, sealed, and reacted at 130° C. for 96 hours to obtain crude product B.

[0028] Step 3, after centrifuging the crude product B, wash twice with 2ml of dimethylacetamide and 2ml of acetone solvent respectively, and dry to obtain zinc phthalocyanine-pyrene-covalent organic framework / single-walled carbon nanotube composite.

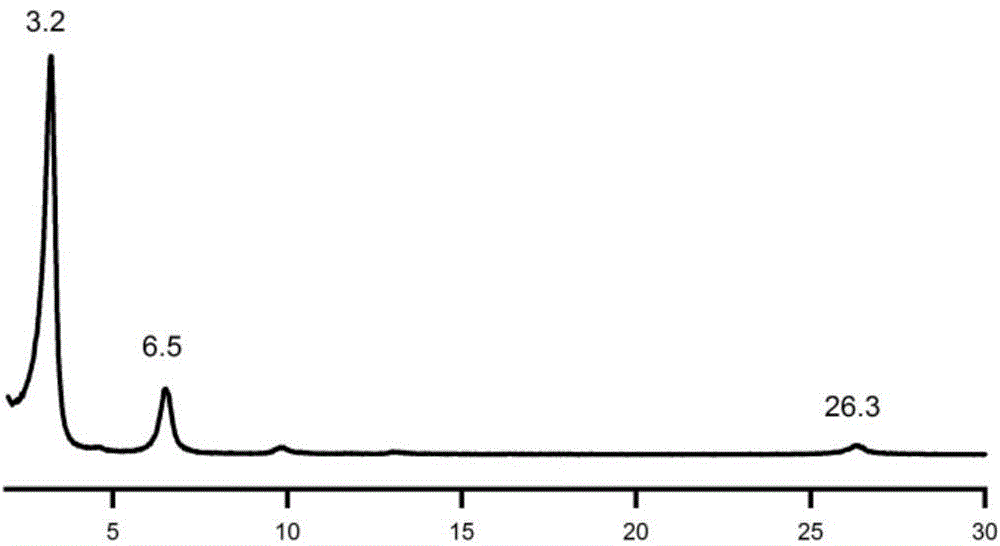

[0029] Implementation effect, the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com