Preparation method for manganese dioxide composite catalyst and synthetic method for 2-pyridylaldehyde

A composite catalyst, manganese dioxide technology, used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem that the catalyst cannot be recycled, pollutes the environment, is easy to pass Oxidation and other problems, to achieve the effect of cost saving, low reaction cost and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

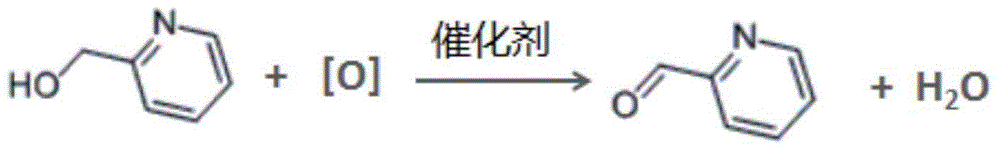

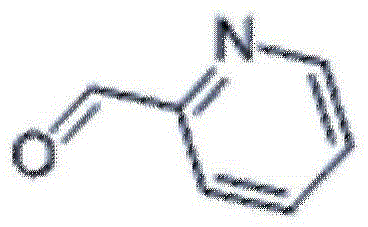

[0038] Such as figure 1 and figure 2 as shown,

[0039] A kind of preparation method of manganese dioxide composite catalyst, its steps are:

[0040] (1) Mix the attapulgite mineral powder and deionized water at a mass ratio of 1:4, stir for 40 minutes, then let it stand for 2 hours, discard the supernatant liquid and the lower layer of sand, and obtain the suspension of attapulgite. The attapulgite obtained after liquid centrifugation is placed in an oven and dried at 80°C for subsequent use;

[0041] (2) Mix the attapulgite obtained in the above steps with 2.5mol / L sulfuric acid solution at a mass ratio of 1:3, stir at 80°C for 1 hour, then cool to room temperature, rinse with deionized water until neutral, and drying and grinding in an oven at 80°C, passing through a 200-mesh sieve to obtain acid-modified attapulgite;

[0042] (3) Add the acid-modified attapulgite obtained in the above steps into 0.15mol / L potassium permanganate solution, the mass ratio of potassium pe...

Embodiment 2

[0054] A kind of preparation method of manganese dioxide composite catalyst, its steps are:

[0055] (1) Mix the attapulgite mineral powder and deionized water at a mass ratio of 1:4, stir for 40 minutes, then let it stand for 2 hours, discard the supernatant liquid and the lower layer of sand, and obtain the suspension of attapulgite. The attapulgite obtained after liquid centrifugation is placed in an oven and dried at 80°C for subsequent use;

[0056] (2) Mix the attapulgite obtained in the above steps with 2.5mol / L sulfuric acid solution at a mass ratio of 1:3, stir at 80°C for 1 hour, then cool to room temperature, rinse with deionized water until neutral, and drying and grinding in an oven at 80°C, passing through a 200-mesh sieve to obtain acid-modified attapulgite;

[0057] (3) Add the acid-modified attapulgite obtained in the above steps into 0.25mol / L potassium permanganate solution, the mass ratio of potassium permanganate solution to attapulgite is 2.5:1, at 40°C ...

Embodiment 3

[0069] A kind of preparation method of manganese dioxide composite catalyst, its steps are:

[0070] (1) Mix the attapulgite mineral powder and deionized water at a mass ratio of 1:4, stir for 40 minutes, then let it stand for 2 hours, discard the supernatant liquid and the lower layer of sand, and obtain the suspension of attapulgite. The attapulgite obtained after liquid centrifugation is placed in an oven and dried at 80°C for subsequent use;

[0071] (2) Mix the attapulgite obtained in the above steps with 2.5mol / L sulfuric acid solution at a mass ratio of 1:3, stir at 80°C for 1 hour, then cool to room temperature, rinse with deionized water until neutral, and drying and grinding in an oven at 80°C, passing through a 200-mesh sieve to obtain acid-modified attapulgite;

[0072] (3) Add the acid-modified attapulgite obtained in the above steps into 0.30mol / L potassium permanganate solution, the mass ratio of potassium permanganate solution to attapulgite is 2:1, at 40°C S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com