Non-oxidation brazing and thermal treatment device of hard alloy cutting teeth

A heat treatment device and cemented carbide technology, applied in heat treatment furnaces, heat treatment equipment, auxiliary devices, etc., can solve the problems of poor heat treatment effect, low welding strength, cracking of brazing materials, etc., to achieve brazing quality, The effect of saving labor costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

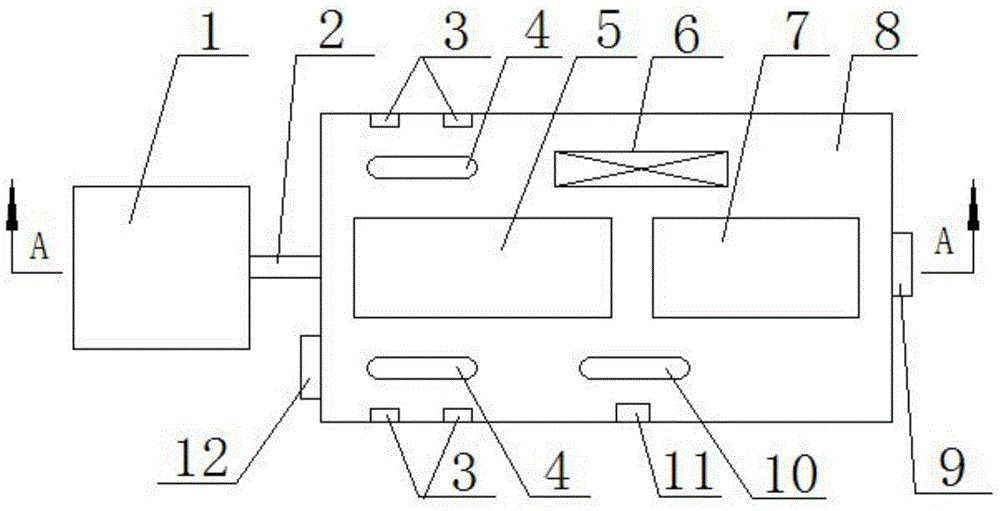

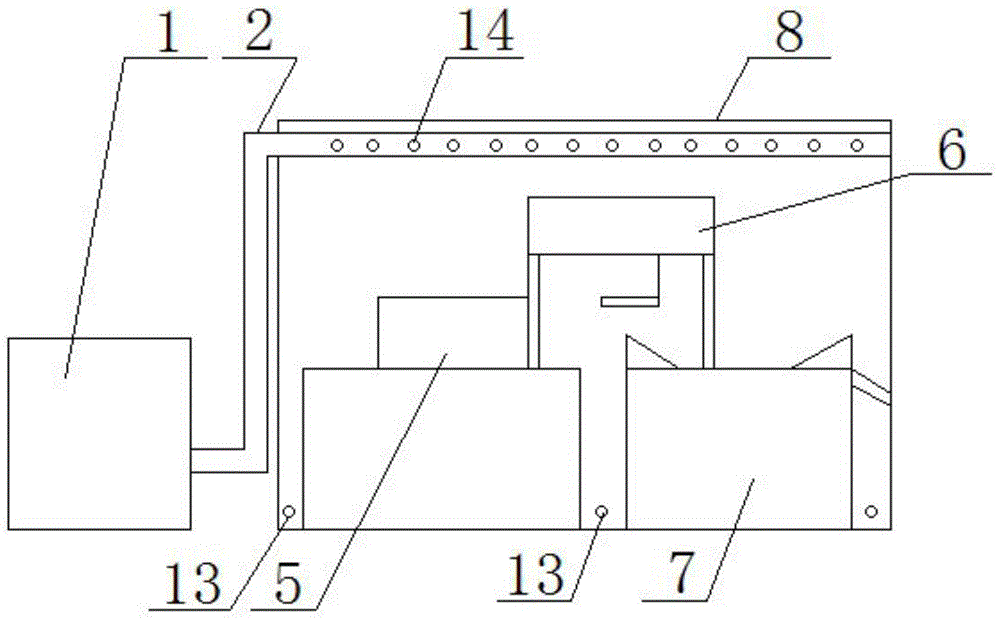

[0016] Such as figure 1 with figure 2 As shown, the non-oxidizing brazing and heat treatment device for hard alloy picks includes a cryogenic box 1, a nitrogen delivery pipeline 2, a heating furnace 5, a quenching tank 7, and a manipulator 6. A nitrogen pipeline 2 is arranged between them, the part of the nitrogen pipeline 2 located in the working chamber 8 is close to the top wall of the working chamber 8, and a nitrogen discharge hole 14 is opened on it; the heating furnace 5, the quenching tank 7 and the manipulator 6 Located in the working chamber 8, the working chamber 8 is a closed structure, and its top is provided with a heating operation hole 3, a heating observation hole 4, a quenching operation hole 11 and a quenching observation hole 10, and its lower part or side wall is provided with an exhaust gas near the bottom. Discharge holes 13; feed holes 12 are provided on the side wall of the working chamber 8 near the heating furnace 5 side, and elastic sealing device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com