High temperature resisting and blue ray resisting protective film

A high-temperature-resistant film and anti-blue light technology, applied in the direction of non-polymer adhesive additives, non-polymer organic compound adhesives, adhesive additives, etc., can solve the problems of easy melting of protective film, skin melanin, skin damage, etc. , to achieve the effects of protecting human eyes, reducing injuries, and improving air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

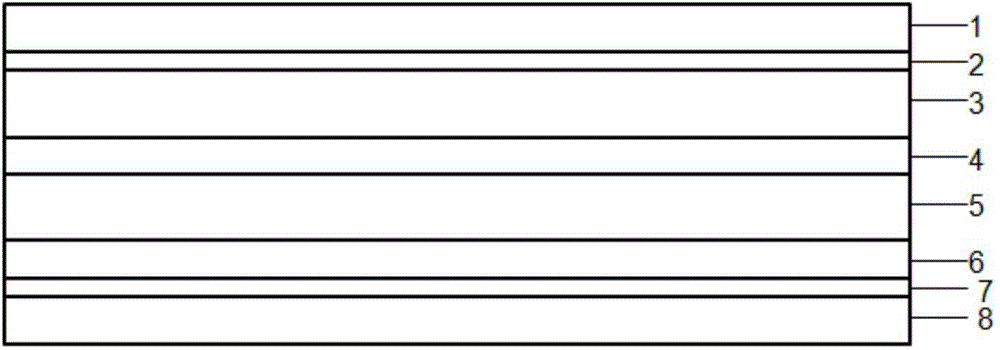

[0091] A high-temperature-resistant and anti-blue light protective film, including from top to bottom:

[0092] The first separation film layer 1, the first base film layer 3, the high temperature resistant film layer 4, the second base film layer 5, the anti-blue light film layer 6 and the second separation film layer 8, wherein,

[0093] The upper surface of the first separation membrane layer 1 and the first base membrane layer 3 is connected by an adhesive 2;

[0094] A high temperature-resistant film layer 4, which is arranged between the first base film layer 3 and the second base film layer 5, is made of high temperature resistant glue;

[0095] Anti-blue light film layer 6, which is arranged between the second base film layer 5 and the second separation film layer 8, and is composed of anti-blue light glue;

[0096] The anti-blue light film layer 6 is connected with the second separation film layer 8 through an adhesive 7;

[0097] The raw material formula of the ant...

specific Embodiment approach 2

[0115] A high-temperature-resistant and anti-blue light protective film, including from top to bottom:

[0116] The first separation film layer 1, the first base film layer 3, the high temperature resistant film layer 4, the second base film layer 5, the anti-blue light film layer 6 and the second separation film layer 8, wherein,

[0117] The upper surface of the first separation membrane layer 1 and the first base membrane layer 3 is connected by an adhesive 2;

[0118] A high temperature-resistant film layer 4, which is arranged between the first base film layer 3 and the second base film layer 5, is made of high temperature resistant glue;

[0119] Anti-blue light film layer 6, which is arranged between the second base film layer 5 and the second separation film layer 8, and is composed of anti-blue light glue;

[0120] The anti-blue light film layer 6 is connected with the second separation film layer 8 through an adhesive 7;

[0121] The raw material formula of the ant...

specific Embodiment approach 3

[0139] A high-temperature-resistant and anti-blue light protective film, including from top to bottom:

[0140] The first separation film layer 1, the first base film layer 3, the high temperature resistant film layer 4, the second base film layer 5, the anti-blue light film layer 6 and the second separation film layer 8, wherein,

[0141] The upper surface of the first separation membrane layer 1 and the first base membrane layer 3 is connected by an adhesive 2;

[0142] A high temperature-resistant film layer 4, which is arranged between the first base film layer 3 and the second base film layer 5, is made of high temperature resistant glue;

[0143] Anti-blue light film layer 6, which is arranged between the second base film layer 5 and the second separation film layer 8, and is composed of anti-blue light glue;

[0144] The anti-blue light film layer 6 is connected with the second separation film layer 8 through an adhesive 7;

[0145] The raw material formula of the ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com