Continuous calcium carbide unloading station and continuous calcium carbide unloading method

A discharge station, continuous technology, applied in the direction of conveyor objects, conveyors, mechanical conveyors, etc., can solve the problems of complex overall structure, inability to realize hopper circulation, unsuitable for continuous unloading of calcium carbide, etc., to improve work efficiency , Simple structure, stable work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

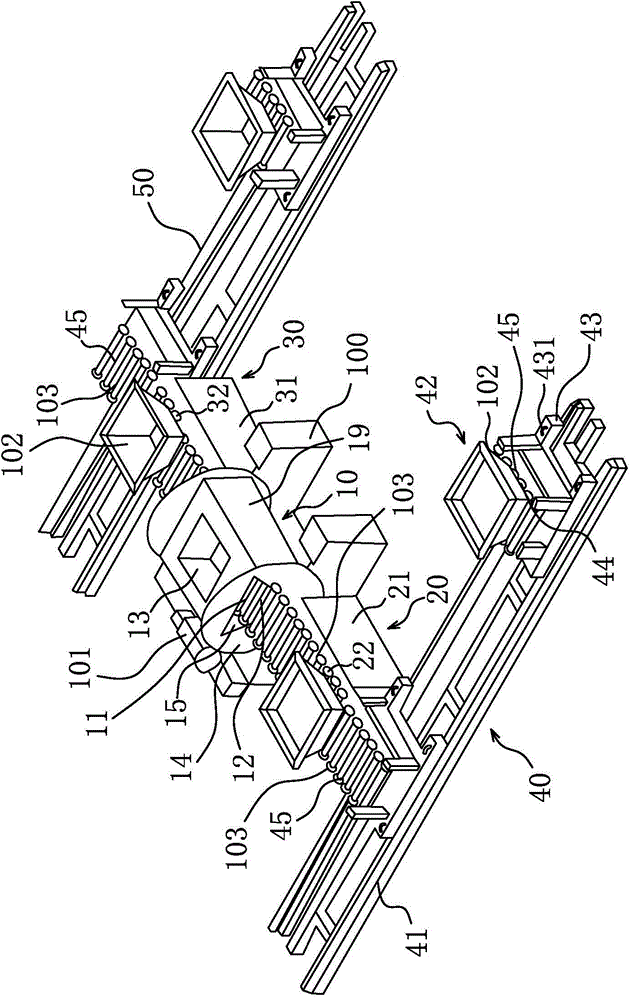

[0030] Such as figure 1 As shown, a continuous calcium carbide unloading station, the unloading station includes a base 100 and a discharge rotation mechanism 10, the discharge rotation mechanism 10 is rotatably connected to the base 100 and connected to the base 100 can A rotary drive mechanism 101 that drives the unloading rotary mechanism 10 to rotate in a circumferential direction. The unloading rotary mechanism 10 has an axially penetrated discharge channel 11, and a first transmission mechanism for transporting the hopper 102 is arranged in the discharge channel 11 12. The side of the discharge rotating mechanism 10 is provided with a discharge port 13 located above the first transmission mechanism 12, and when the discharge rotation mechanism 10 rotates, the hopper 102 located on the first transmission mechanism 12 is positioned in the discharge channel In 11, one end of the discharge rotation mechanism 10 is provided with a hopper input transmission mechanism 20 that c...

Embodiment 2

[0040] This embodiment provides a continuous calcium carbide unloading method for a continuous calcium carbide unloading station, the method comprising the following steps:

[0041] Step A, make unloading station, such as figure 1 As shown, the unloading station includes a machine base 100 and an unloading rotating mechanism 10. The unloading rotating mechanism 10 is rotatably connected to the machine base 100 and is connected to the machine base 100 to drive the unloading rotating mechanism 10 to rotate in a circumferential direction. The rotary drive mechanism 101, the discharge rotary mechanism 10 has a discharge channel 11 through the axial direction, in the discharge channel 11 is provided with a first transmission mechanism 12 for the transmission hopper 102, the discharge rotary mechanism The side of 10 is provided with a discharge opening 13 located above the first transmission mechanism 12, and when the discharge rotation mechanism 10 rotates, the hopper 102 on the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com