A kind of preparation method of barium titanate/graphene composite nanomaterial

A graphene composite and nano-material technology, applied in the direction of graphene, titanate, nano-carbon, etc., can solve problems such as no related reports, and achieve the effect of simple process, high purity and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

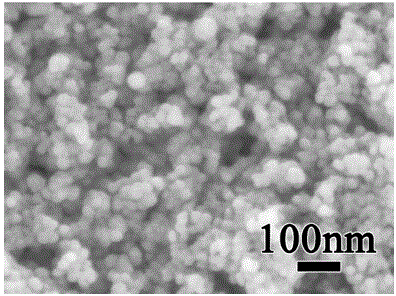

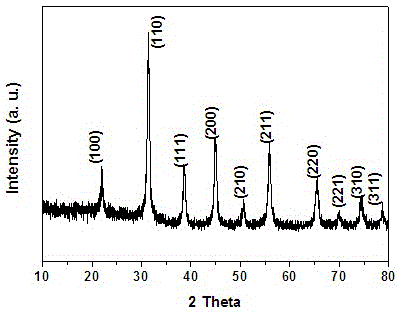

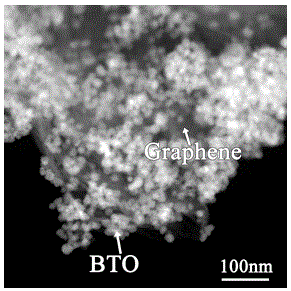

Image

Examples

Embodiment 1

[0017] 1) Dissolve 0.25mmol tetrabutyl titanate in 5ml ethylene glycol methyl ether, drop in ammonia water with a mass concentration of 30% as a precipitant to precipitate titanium ions, and obtain titanium oxyhydroxide precipitation;

[0018] 2) Add the titanium oxyhydroxide precipitation obtained in step 1), 10ml of graphene oxide aqueous solution with a concentration of 0.5g / L and 20ml of ethylenediamine / ethanolamine mixture into the inner tank of the reactor, wherein ethylenediamine and The volume ratio of ethanolamine is 1:1, stirring at room temperature for 6h;

[0019] 3) Dissolve 0.25mmol of barium acetate in 2ml of deionized water, and add it into the liner of the reaction kettle containing the mixed solution in step 2), then add 2.74g of potassium hydroxide, and stir at room temperature for 30min;

[0020] 4) Put the inner liner of the reaction kettle equipped with the reaction materials into the reaction kettle, seal it tightly, and o After 12 hours of heat preserv...

Embodiment 2

[0022] 1) Dissolve 0.3mmol tetrabutyl titanate in 5ml ethylene glycol methyl ether, drop in 30% ammonia water as a precipitant to precipitate titanium ions, and obtain titanium oxyhydroxide precipitation;

[0023] 2) Add the titanium oxyhydroxide precipitation obtained in step 1), 10ml of a 1g / L graphene oxide aqueous solution and 20ml of ethylenediamine / ethanolamine mixture into the inner tank of the reactor, wherein ethylenediamine and ethanolamine The volume ratio is 1:1, stirred at room temperature for 8h;

[0024] 3) Dissolve 0.3mmol of barium acetate in 2ml of deionized water, add it to the liner of the reaction kettle containing the mixed solution in step 2), then add 5.48g of potassium hydroxide, and stir at room temperature for 60min;

[0025] 4) Put the inner liner of the reaction kettle equipped with the reaction materials into the reaction kettle, seal it tightly, and o After 12 hours of heat preservation at C, the temperature was naturally lowered to room tempera...

Embodiment 3

[0028] 1) Dissolve 0.5mmol tetrabutyl titanate in 5ml ethylene glycol methyl ether, drop in ammonia water with a mass concentration of 30% as a precipitant to precipitate titanium ions, and obtain titanium oxyhydroxide precipitation;

[0029] 2) Add the titanium oxyhydroxide precipitation obtained in step 1), 10ml of a 2g / L graphene oxide aqueous solution and 20ml of ethylenediamine / ethanolamine mixture into the inner tank of the reactor, wherein ethylenediamine and ethanolamine The volume ratio is 1:1, stirred at room temperature for 10h;

[0030] 3) Dissolve 0.5mmol of barium acetate in 2ml of deionized water, add it to the liner of the reaction kettle containing the mixed solution in step 2), then add 10.96g of potassium hydroxide, and stir at room temperature for 60min;

[0031] 4) Put the inner liner of the reaction kettle equipped with the reaction materials into the reaction kettle, seal it tightly, and o After 12 hours of heat preservation at C, the temperature was na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com