A method for extracting eucommia gum from eucommia bark by using an enzymolyzer

A technology using an enzymatic hydrolyzer and Eucommia gum, which is applied in the field of extracting Eucommia gum from the bark of Eucommia ulmoides by using an enzymatic hydrolyzer, and can solve problems such as the absence of an extraction method for Eucommia gum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

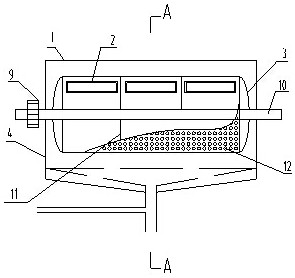

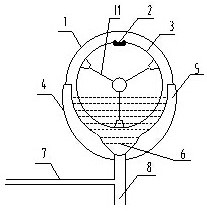

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] A method for extracting Eucommia gum from Eucommia bark using an enzymolyzer, comprising the steps:

[0034] 1), first use a hay cutter to cut the bark of Eucommia bark as a raw material into an area no larger than 25cm 2 Then put it into clear water at room temperature and soak it for 12 hours, then take it out, put it into the blasting machine and blast it to get Eucommia bark intermediate I for later use;

[0035] In this step, the blasting temperature is controlled below 50°, the blasting pressure is controlled between 1.4MPa, and the blasting time is controlled at 0.3S;

[0036] 2), the Eucommia bark intermediate I obtained in step 1) was put into the aqueous solution of protease and stirred and washed repeatedly for 5 hours, and then stirred and washed repeatedly with clean water for 1.5 hours to obtain the Eucommia bark...

Embodiment 2

[0044] A method for extracting Eucommia gum from Eucommia bark using an enzymolyzer, comprising the steps:

[0045] 1), first use the hay cutter to cut the eucommia bark as raw material into an area no larger than 25cm 2 Then put it into clear water at room temperature and soak it for 12.5 hours, then remove it, put it into a blasting machine, and blast it to obtain Eucommia bark intermediate I for later use;

[0046] In this step, the blasting temperature is controlled below 50°, the blasting pressure is controlled between 1.6MPa, and the blasting time is controlled at 0.4S;

[0047] 2) Put the eucommia bark intermediate I obtained in step 1) into the aqueous solution of protease and repeatedly stir and wash for 5.5 hours, then repeatedly stir and wash with water for 2 hours to obtain the eucommia bark intermediate II:

[0048] When washing in this step, the various components are configured according to the following parts by weight: 100 parts of Eucommia bark intermediate ...

Embodiment 3

[0055] A method for extracting Eucommia gum from Eucommia bark using an enzymolyzer, comprising the steps:

[0056] 1), first use the hay cutter to cut the eucommia bark as raw material into an area no larger than 25cm 2 Then put it into clear water at room temperature and soak for 13 hours, then remove it, put it into a blasting machine, and blast it to obtain Eucommia bark intermediate I for later use;

[0057] In this step, the blasting temperature is controlled below 50°, the blasting pressure is controlled between 1.8MPa, and the blasting time is controlled at 0.5S;

[0058] 2), the Eucommia bark intermediate I obtained in step 1) was put into the aqueous solution of protease, stirred and washed repeatedly for 6 hours, and then stirred and washed repeatedly with clean water for 2.5 hours to obtain the Eucommia bark intermediate II:

[0059] When washing in this step, the various components are configured according to the following parts by weight: 110 parts of Eucommia b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com