Ultrafine calcium carbonate powder acetal modifier

A technology of superfine calcium carbonate and modifier, which is applied in the direction of fibrous filler, dyed low-molecular organic compound treatment, dyed high-molecular organic compound treatment, etc. It can solve the problems of no discovery, achieve convenient operation, low production cost, easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

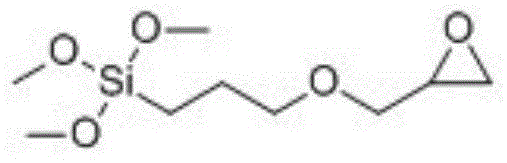

[0014] The superfine calcium carbonate powder acetal modifier of the present invention is characterized in that: by weight, the formula consists of 3-5 parts of polyvinyl acetal resin, 25-30 parts of glycidyl ether oxypropyl trimethoxysilane , 5-8 parts of sodium carbonate, 3-5 parts of acrylic vinylpyridine copolymer, 5-8 parts of ethylene glycol, 5-6 parts of triacetin, 1-2 parts of dioctyltin, and 50-60 parts of water .

Embodiment 2

[0016] The preparation method of superfine calcium carbonate powder acetal modifier of the present invention is characterized in that: by weight, the formula consists of 3-5 parts of polyvinyl acetal resin, glycidyl ether oxypropyl trimethoxysilane 25- 30 parts, 5-8 parts of sodium carbonate, 3-5 parts of vinylpyridine acrylic acid copolymer, 5-8 parts of ethylene glycol, 5-6 parts of triacetin, 1-2 parts of dioctyltin, 50-60 parts of water The composition is mixed at 85-95°C for 20-30 minutes to obtain the product.

Embodiment 3

[0018] The preparation method of ultrafine calcium carbonate powder polyurethane modifier of the present invention is characterized in that: by weight, the formula consists of 5 parts of polyvinyl acetal resin, 25 parts of glycidyl ether oxypropyltrimethoxysilane, sodium carbonate 5 parts, 3 parts of acrylic acid vinylpyridine copolymer, 5 parts of ethylene glycol, 5 parts of triacetin, 1 part of dioctyltin, 50 parts of water, stir at 85-95 ℃ for 20-30 minutes to get the product .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com