Purple disperse dye with high washing fastness and sublimation fastness and preparation method of purple disperse dye

A technology of sublimation fastness and disperse dyes, applied in chemical instruments and methods, dyeing methods, azo dyes, etc., can solve the problems of unsatisfactory sublimation fastness and achieve the effect of high washing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Preparation of diazonium salt

[0048] In a 250ml four-necked flask with stirring, adding 30 grams of concentration is 99% acetic acid, 15 grams of concentration is 99% propionic acid, 15g concentration is 98% sulfuric acid, and slowly adding 20.4g N- Methyl-4-amino-5-cyanophthalimide (purity 98.0%), and stir at this temperature until the solid is completely dissolved (generally 1 hour can be completely dissolved), and the ice-salt bath is cooled to -5 degree, control -10 degrees to 0 degrees and slowly add a nitrosylsulfuric acid solution with a percentage of 13.5g (the percentage refers to the amount converted to 100%, that is, the amount of nitrosylsulfuric acid contained in the solution), The dropwise addition time is 1-2h. After the dropwise addition, continue to keep warm and stir for 3h. Use starch potassium iodide test paper to test in ice water. If it turns blue, stop stirring for later use.

[0049] 2. Coupling reaction

[0050] In the 2000ml large beaker...

Embodiment 2-6

[0053] Synthetic structure (I-2) to structure (I-6) according to the operation method of embodiment 1

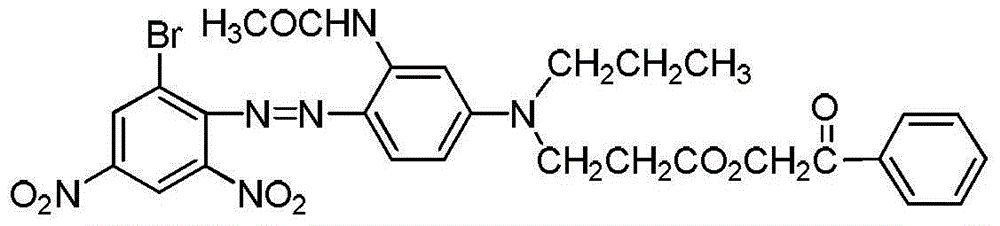

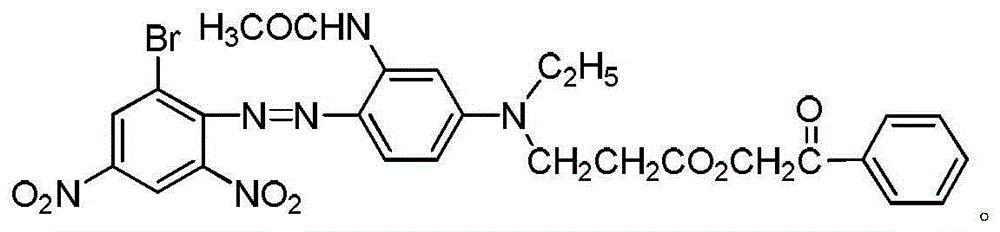

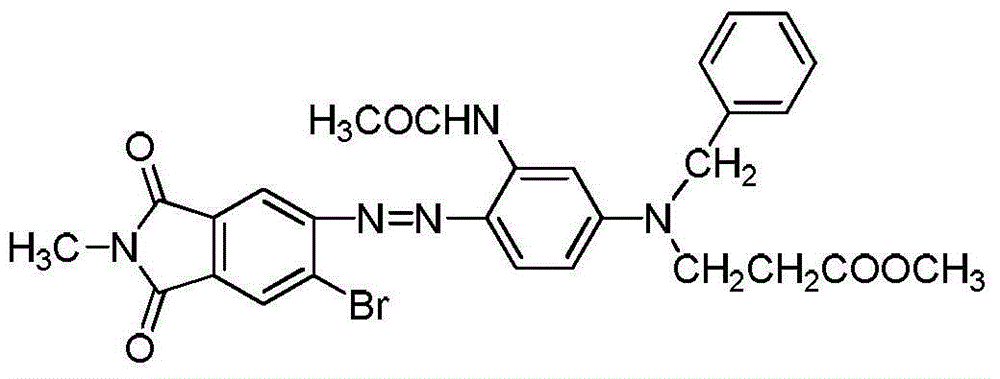

[0054]

[0055]

Embodiment 7

[0056] Embodiment 7: dyeing embodiment

[0057] Each take 2 grams of the disperse dyes with high washing fastness and high light fastness obtained in Examples 1-6, disperse them in 500 milliliters of water, mix with 60 milliliters of water after absorbing 20 milliliters, adjust the pH of the bath with acetic acid 5. At the same time when the temperature is raised to 70°C, 2 grams of polyester cloth is put into it for dyeing, and the temperature is raised from 70°C to 130°C within 30 minutes, and the temperature is kept for 45 minutes, and sampling starts when it is cooled to 90°C. Get dyed fabrics No. 1 to No. 9, and use national standards GB / T3921-1997, GB / T3920-1997, GB / T8427-1998, GB / T5718-1997 to test their washing resistance, rubbing fastness, sun resistance and sublimation resistance respectively Fastness and diffusion properties, the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com