Antibacterial printing ink composition and preparation method thereof

A technology of ink composition and antibacterial agent, applied in ink, household utensils, applications, etc., can solve problems affecting health, cross-infection, etc., and achieve good coating or printing effects, low cost, and excellent adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

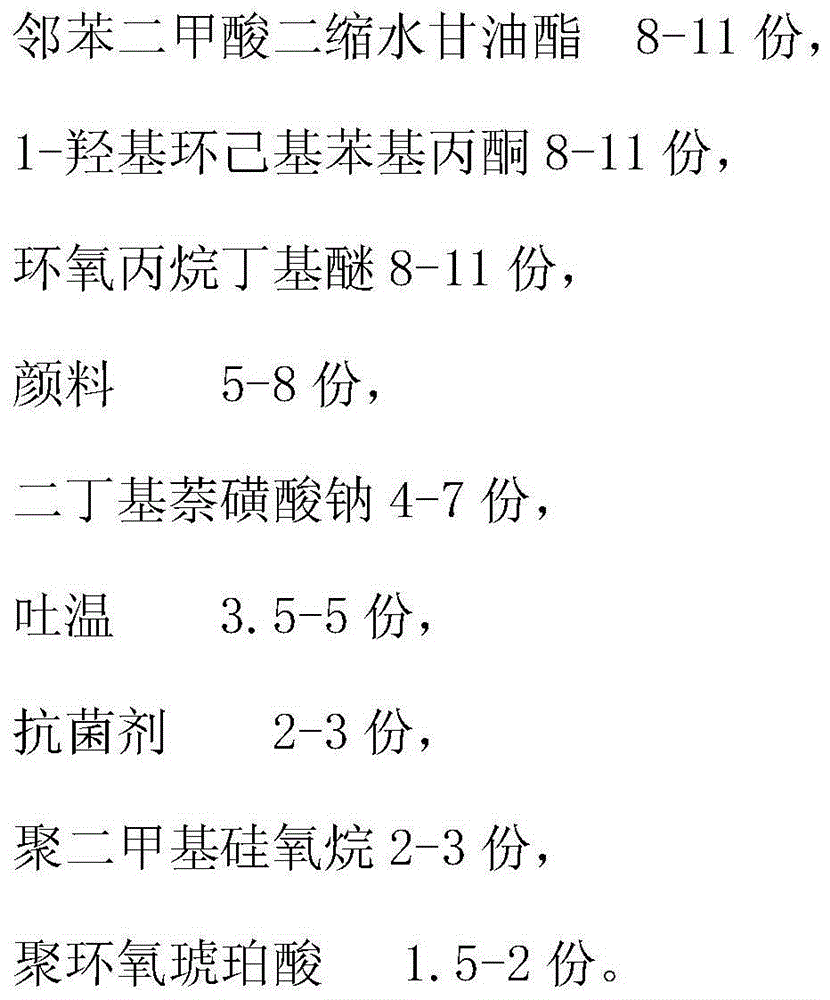

Method used

Image

Examples

Embodiment 1

[0031] (1) Take carbon black 5kg, add trimethoprim 0.29kg, nano-titanium dioxide 0.58kg, nano-zinc oxide 1.16kg, diglycidyl phthalate 11kg, 1-hydroxycyclohexyl phenylacetone 8kg and Propylene oxide butyl ether 11kg, mix well;

[0032] (2) Take by weighing 6 kg of sodium dibutylnaphthalene sulfonate, 3 kg of polydimethylsiloxane, 3.5 kg of Tween 20 and 1.5 kg of polyepoxysuccinic acid, and add it to a three-roll mill and grind for 15 minutes;

[0033] (3) The product of step 1 and the product of step 2 were ultrasonicated at 55° C. for 15 minutes, and degassed under vacuum for 1 hour to obtain an antibacterial ink composition.

[0034] The performance test results of the prepared antibacterial ink composition are shown in Table 1.

Embodiment 2

[0036] (1) Take by weighing 8kg Pigment Yellow 74, add nano titanium dioxide 3kg, diglycidyl phthalate 8kg, 1-hydroxycyclohexyl phenylacetone 11kg and propylene oxide butyl ether 8kg successively, mix uniformly;

[0037] (2) Take by weighing 4kg of sodium dibutylnaphthalene sulfonate, 3kg of polydimethylsiloxane, 5kg of Tween 60 and 2kg of polyepoxysuccinic acid, and add it to a three-roll mill and grind for 10 minutes;

[0038] (3) The product of step 1 and the product of step 2 were ultrasonicated at 60° C. for 20 minutes, and defoamed for 2 hours under vacuum conditions to obtain an antibacterial ink composition.

[0039] The performance test results of the prepared antibacterial ink composition are shown in Table 1.

Embodiment 3

[0041] (1) Take by weighing 6kg Pigment Yellow 155, add trimethoprim 2kg, diglycidyl phthalate 11kg, 1-hydroxycyclohexyl phenylacetone 10kg and propylene oxide butyl ether 9kg successively, mix well;

[0042] (2) Take by weighing 7kg of sodium dibutylnaphthalene sulfonate, 2kg of polydimethylsiloxane, 3.5kg of Tween 40 and 1.5kg of polyepoxysuccinic acid, and add it to a three-roll mill and grind for 20 minutes;

[0043] (3) The product of step 1 and the product of step 2 were ultrasonicated at 70° C. for 25 minutes, and defoamed under vacuum for 2 hours to obtain an antibacterial ink composition.

[0044] The performance test results of the prepared antibacterial ink composition are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com