A kind of powder coating with wrinkle effect that is not easy to expose substrate after curing and preparation method thereof

A powder coating and wrinkle technology, applied in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of fine particle size, low density, breaking the relative equilibrium state, etc., to achieve balance of inner surface tension and uniform wrinkle effect , The effect of not easily revealing the bottom cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The base powder composition is made of the following raw materials in parts by weight:

[0061] 60 parts of polyester resin with an acid value of 30 mgKOH / g and a viscosity of 3500 (ICI, mPa.s / 200°C)

[0062] Triglycidyl isocyanurate 5 parts

[0063] Quaternary ammonium salt accelerator 0.3 parts

[0064] Titanium dioxide 5 parts

[0065] Barium sulfate 30 parts

[0066] Auxiliary 5 parts.

[0067] The acid value of the polyester resin is 30 mgKOH / g, the viscosity is 3500 (ICI, mPa.s / 200°C), and the horizontal flow is 20~30mm.

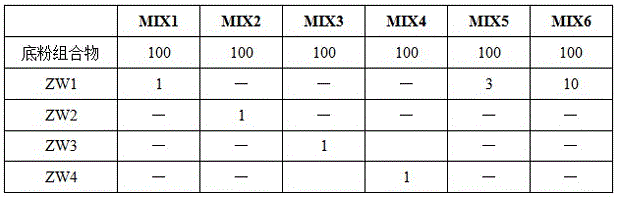

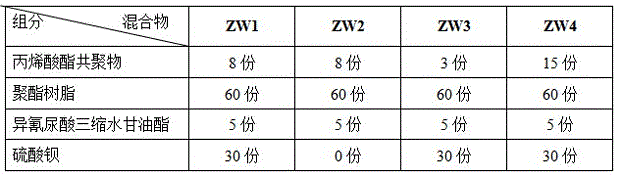

[0068] The wrinkle agent composition is made of the following raw materials in parts by weight; wherein ZW2 and ZW4 are used as comparative examples.

[0069]

[0070] (a) Weigh the components in the foundation powder composition and the components in the wrinkle agent composition respectively according to the proportion, place them in the mixing tank respectively, fully mix and break;

[0071] (b) The crushed materials enter the extrud...

Embodiment 2

[0076] The difference with embodiment 1 is:

[0077] The base powder composition is made of the following raw materials in parts by weight:

[0078] 45 parts of polyester resin

[0079] Triglycidyl isocyanurate 4 parts

[0080] Quaternary ammonium salt accelerator 0.5 parts

[0081] Titanium dioxide 10 parts

[0082] Barium sulfate 30 parts

[0083] Auxiliary 8 parts.

[0084] The acid value of the polyester resin is 30 mgKOH / g, the viscosity is 3500 (ICI, mPa.s / 200°C), and the horizontal flow is 20~30mm.

[0085] The foundation powder composition and the wrinkle agent composition ZW1 were dry mixed at a weight ratio of 100:5 to obtain a mixture MIX7.

Embodiment 3

[0087] The difference with embodiment 1 is:

[0088] The base powder composition is made of the following raw materials in parts by weight:

[0089] 65 parts of polyester resin

[0090] Triglycidyl isocyanurate 10 parts

[0091] 1 part quaternary ammonium salt accelerator

[0092] Titanium dioxide 20 parts

[0093] Barium sulfate 30 parts

[0094] Auxiliary 10 parts.

[0095] The acid value of the polyester resin is 30 mgKOH / g, the viscosity is 3500 (ICI, mPa.s / 200°C), and the horizontal flow is 20~30mm.

[0096] The foundation powder composition and the wrinkle agent composition ZW1 were dry mixed at a weight ratio of 100:2 to obtain a mixture MIX8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com