Intelligent microbial sample processing robot

A technology of intelligent robots and microorganisms, applied in the direction of biomass post-treatment, biomass pre-treatment, enzymology/microbiology devices, etc., can solve the problems of operators' susceptibility to germs, low efficiency of microbial inoculation, and adverse effects, etc., to eliminate The risk of infection, the elimination of uncertainties, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Referring to the accompanying drawings, the present invention will be further described in detail with specific embodiments.

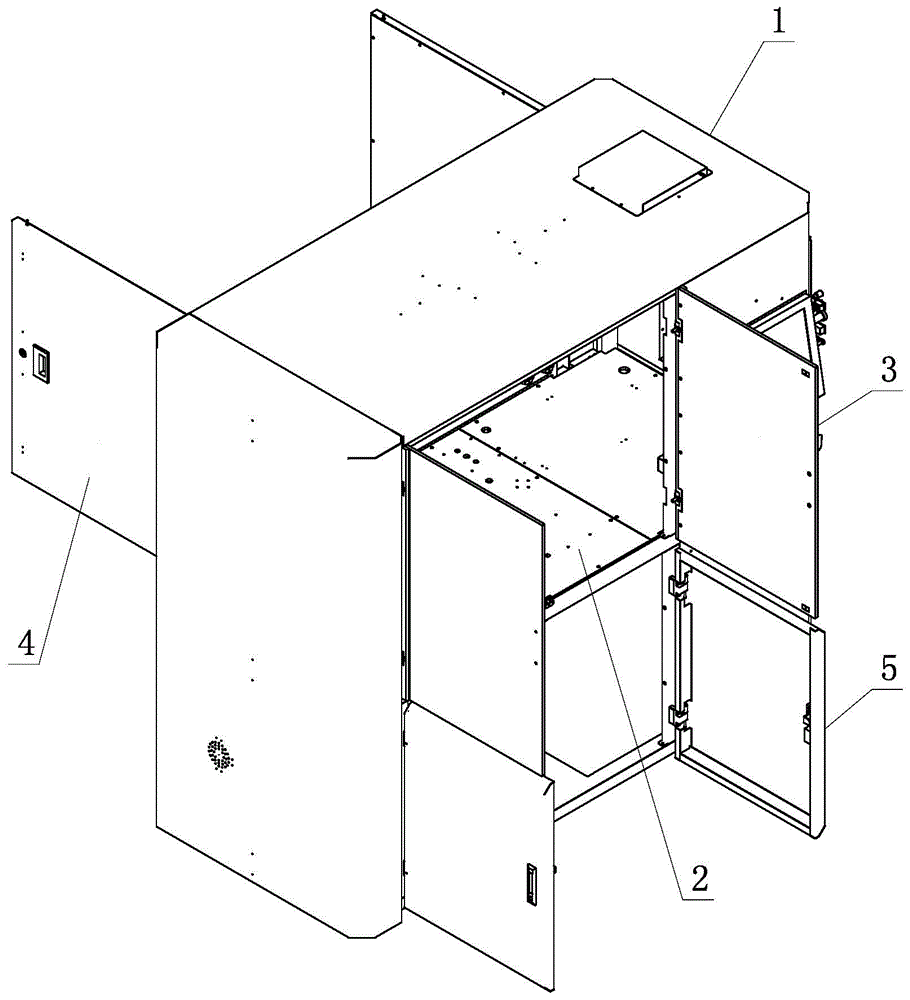

[0049] Such as figure 1 As shown, there is a platform 2 arranged horizontally in the cabinet 1, and the platform 2 is used for installing various automatic processing mechanisms. The space below the machine platform 2 is a storage room, which is connected with a storage room door 5 . A front door 3 and a rear door 4 are connected to the space above the machine platform 2 . The front door 3 and the back door 4 can seal the space above the machine platform 2 where the automatic processing mechanism is placed, so as to isolate the germ contamination in the sample processing process and prevent the operator from infecting the germ. Front door 3 and back door 4 can be made of transparent materials such as glass, plastics.

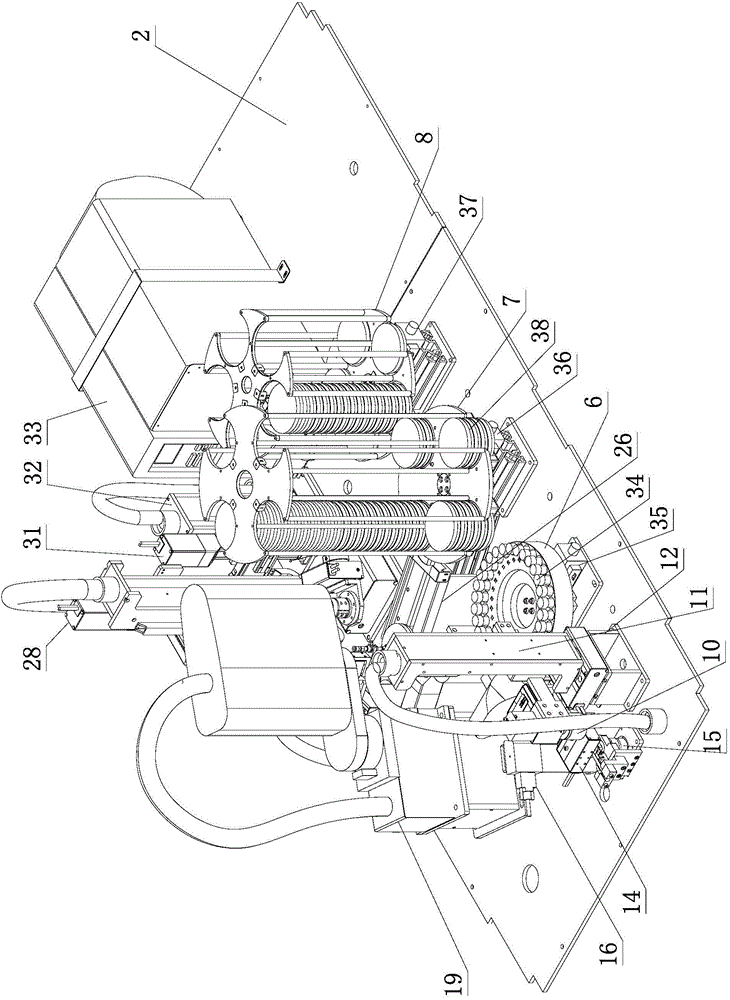

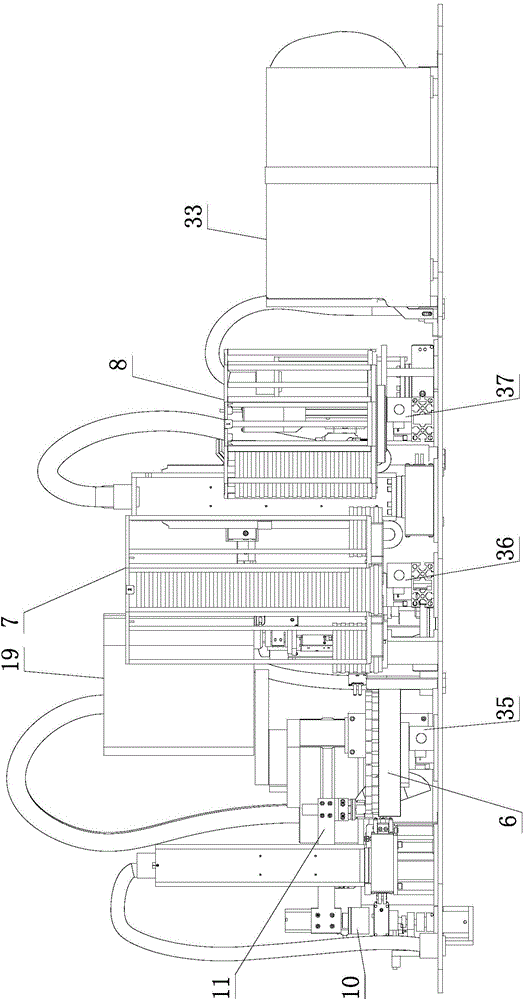

[0050] Such as figure 2 , 3 As shown in and 4, the sample test tube is automatically removed from the cover and the handli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com