A casting method for the inlaid production of centrifugal composite sleeves for wire rod rolls

A centrifugal compounding and rolling technology, applied in the field of online bar roll production, can solve the problems of reducing the normal use frequency of rolls and scrapping, unable to meet the use of high-speed wire rod mills, and unusable roll surfaces, saving time and manpower for changing grooves and rolls , The effect of increasing the amount of steel passing through a single groove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A casting method for making wire rods and rolls inlaid with centrifugal composite sleeves, comprising the following steps:

[0038] (1) Select the outer material of the centrifugal double-layer composite sleeve:

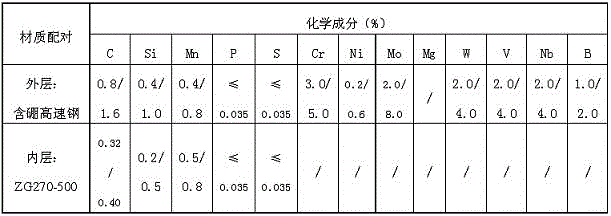

[0039] Boron-containing high-speed steel, high-chromium cast iron, Cr4, and bainite nodular graphite centrifugal composite I are used as the outer layer of the centrifugal double-layer composite sleeve;

[0040] ⑵Select the inner material of the centrifugal double-layer composite sleeve:

[0041] ZG270-500, ductile iron, graphite steel, and 16Mn are used as the inner layer of the centrifugal double-layer composite sleeve;

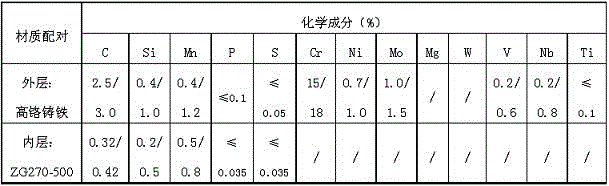

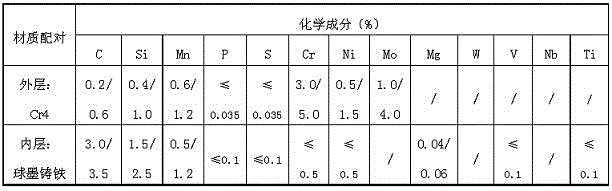

[0042] ⑶ Inner and outer material matching:

[0043] Using computer to simulate the deformation curves of four kinds of centrifugal double-layer composite sleeve outer layer and four kinds of centrifugal double-layer composite sleeve inner layer, a total of eight materials, paired in pairs at 300°C, 650°C, and 1050°C temperature ranges, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com