Corrosion-resistant flat bulb steel used in cargo oil tank of oil tanker and smelting technology thereof

A cargo oil tank and bulb flat steel technology, applied in the metallurgical field, can solve problems such as difficulty, high maintenance cost, complicated operation procedures, etc., and achieve the effect of prolonging the service life and reducing the maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

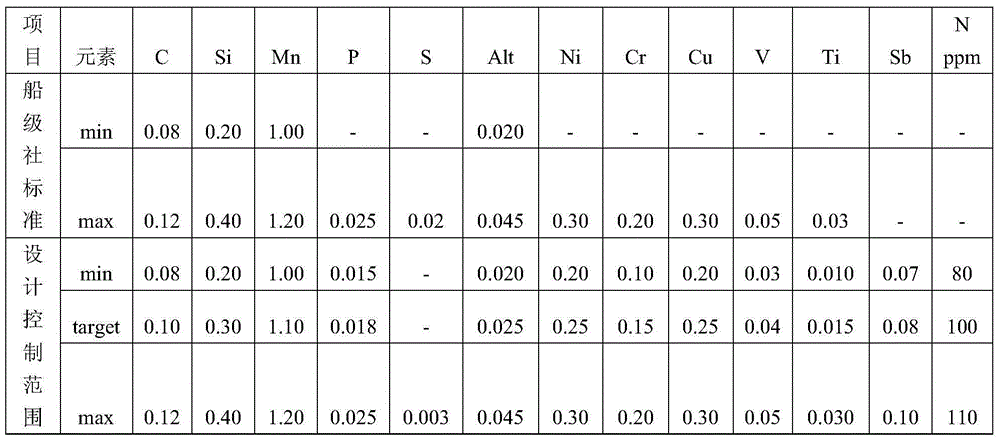

[0033] Corrosion-resistant steel for cargo oil tanks of oil tankers contains by weight percentage: C: 0.08%, Si: 0.20%, Mn: 1.00%, P: 0.025%, S: 0.003%, Alt: 0.020%, Ni: 0.20%, Cr : 0.10%, Cu: 0.20%, V: 0.03%, Ti: 0.030%, Sb: 0.10%, also contains N: 80ppm, and the rest is Fe and unavoidable impurities.

[0034] Its manufacturing method comprises the following steps:

[0035](1) In the 100t EBT electric arc furnace smelting process, the Cu content is tested before tapping, and according to the analysis results, pure copper alloy is added during the tapping process to adjust the copper content to the design range. The amount of pure copper alloy added refers to 10kg copper Copper 0.01% standard for control;

[0036] (2) In the primary refining process of 100t LF, alloys of appropriate grades (100kg ferrosilicon, 100kg low carbon ferrochrome, 80kg ferrovanadium, 140kg nickel plate, 200kg low carbon ferromanganese, 20kg ferrophosphorus, 150kg nickel copper) will be used in combin...

Embodiment 2

[0041] Corrosion-resistant steel for cargo oil tanks of oil tankers contains by weight percentage: C: 0.10%, Si: 0.30%, Mn: 1.20%, P: 0.015%, S: 0.0025%, Alt: 0.025%, Ni: 0.30%, Cr : 0.15%, Cu: 0.30%, V: 0.05%, Ti: 0.010%, Sb: 0.08%, also contains N: 110ppm, and the rest is Fe and unavoidable impurities.

[0042] Its manufacturing method comprises the following steps:

[0043] (1) In the 100t EBT electric arc furnace smelting process, the Cu content is tested before tapping, and according to the analysis results, pure copper alloy is added during the tapping process to adjust the copper content to the design range. The amount of pure copper alloy added refers to 10kg copper Copper 0.01% standard for control;

[0044] (2) In the primary refining process of 100t LF, alloys of appropriate grades (95kg ferrosilicon, 105kg low carbon ferrochrome, 75kg ferrovanadium, 150kg nickel plate, 210kg low carbon ferromanganese, 18kg ferrophosphorus, 138kg nickel copper) will be used in comb...

Embodiment 3

[0049] Corrosion-resistant steel for cargo oil tanks of oil tankers contains by weight percentage: C: 0.12%, Si: 0.40%, Mn: 1.10%, P: 0.018%, S: 0.002%, Alt: 0.045%, Ni: 0.25%, Cr : 0.20%, Cu: 0.25%, V: 0.04%, Ti: 0.015%, Sb: 0.07%, also contains N: 100ppm, and the rest is Fe and unavoidable impurities.

[0050] Its manufacturing method comprises the following steps:

[0051] (1) In the 100t EBT electric arc furnace smelting process, the Cu content is tested before tapping, and according to the analysis results, pure copper alloy is added during the tapping process to adjust the copper content to the design range. The amount of pure copper alloy added refers to 10kg copper Copper 0.01% standard for control;

[0052] (2) In the primary refining process of 100t LF, alloys of appropriate grades (106kg ferrosilicon, 123kg low carbon ferrochrome, 82kg ferrovanadium, 145kg nickel plate, 195kg low carbon ferromanganese, 19kg ferrophosphorus, 144kg nickel copper) will be used in comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com