Ultra-high-molecular-weight polyethylene protofilament drafting method

An ultra-high molecular weight, polyethylene technology, applied in the direction of stretch spinning, artificial filament heat treatment, etc., can solve the problems of low fiber strength, the folded chain structure cannot effectively transmit loads, etc., to improve mechanical properties and improve production stability. properties, and the effect of realizing the mechanical properties of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and 4

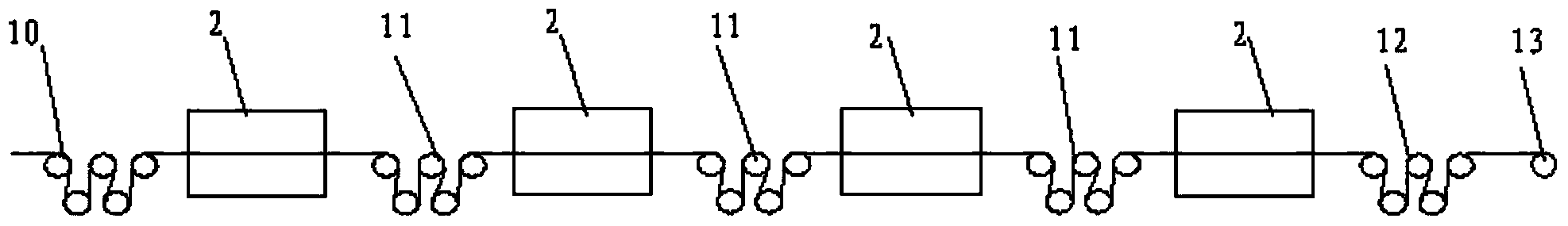

[0032] This example provides an improved drafting method, which adopts such as figure 1 The traditional drafting device shown in the figure, the technological process is that the dry-freeze rubber yarn passes through 1# roller, 1# hot box, 2# roller, 2# hot box, 3# roller, 3# hot box, 4# roller, 4 #Hot box, 5# rollers are wound into rolls by the first winding roller 13 at last. The improvement lies in the change of process conditions, especially the control of the drawing deformation rate and the control of the residence time of the tow in the hot box. The specific process parameters are shown in Table 1 and Table 2.

Embodiment 2 and 5

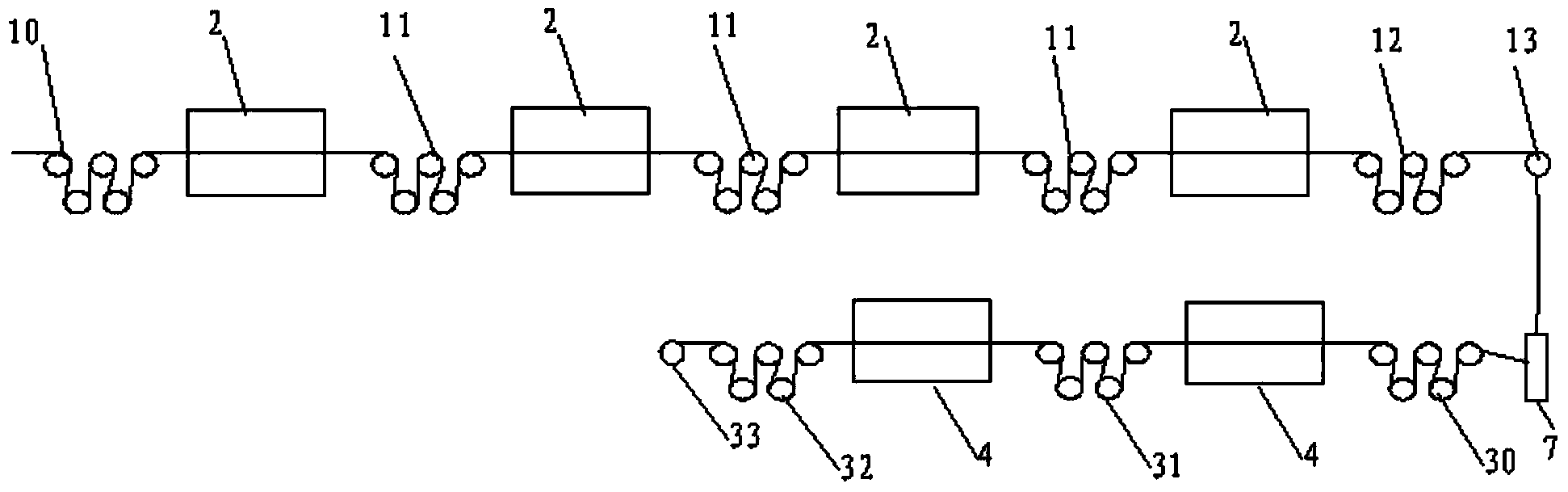

[0034] This example provides a kind of method that adopts improved drafting device and method to draft jelly silk. Such as figure 2As shown, the improved drafting device has the same figure 1 In addition to the same five sets of first drafting rollers and four-stage first heat boxes 2, there are also three sets of second draft rolls, two-stage second heat boxes 4 and second winding rolls 33. Three sets of second drafting rolls are successively the first feed roll 30 arranged in front of the second hot box 4, the second intermediate roll 31 arranged between the adjacent secondary second hot boxes 4, and the last stage The second discharge roll 32 behind the second hot box 4 (for convenience of description, 1#, 2#, and 3# rolls are used to represent these three groups of second drafting rolls below, and the secondary second hot box 4 is used successively by 1 #, 2# hot box means). In addition, in front of the 1# roll of the second drafting roll, there is also a tension frame...

Embodiment 3 and 6

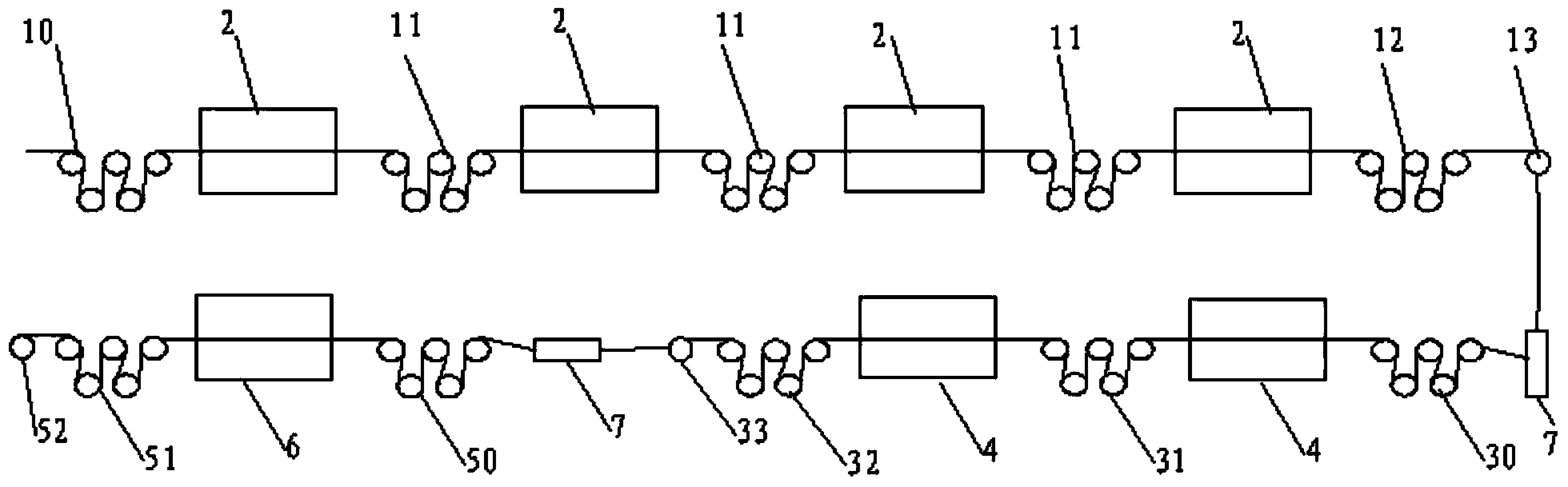

[0040] This example provides a kind of method that adopts improved drafting device and method to draft jelly silk. Such as image 3 As shown, the improved drafting device has the same figure 2 In addition to the same five sets of first drafting rolls, four sets of first hot box 2, three sets of second drafting rolls and two sets of second hot box 4, there are also two sets of third drafting rolls, one level of second hot box Box 6 and third winding drum 52 . Two groups of the third drafting rollers are respectively the third feeding roller 50 and the third discharging roller 51 located at the front and the rear of the third hot box 6 (for convenience of description, these two groups of the third drafting rollers will be referred to as 1 below. #, 2# rollers represent, and the first-level second hot box 4 is expressed with 1# hot box). In addition, a tension frame 7 is respectively provided in front of the 1# roller of the second drafting roller and the 1# roller of the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com