Novel modularization vertical type water pipe waste heat boiler

A technology of vertical water pipe and waste heat boiler, which is applied in the field of flue-type waste heat new vertical water pipe waste heat boiler structure and modular vertical water pipe waste heat boiler, which can solve problems such as difficult construction, high consumption, and bad influence on corporate image , to achieve the effect of reducing floor space and resource consumption, shortening the manufacturing cycle and installation cycle, and saving heavy steel frames and steel materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

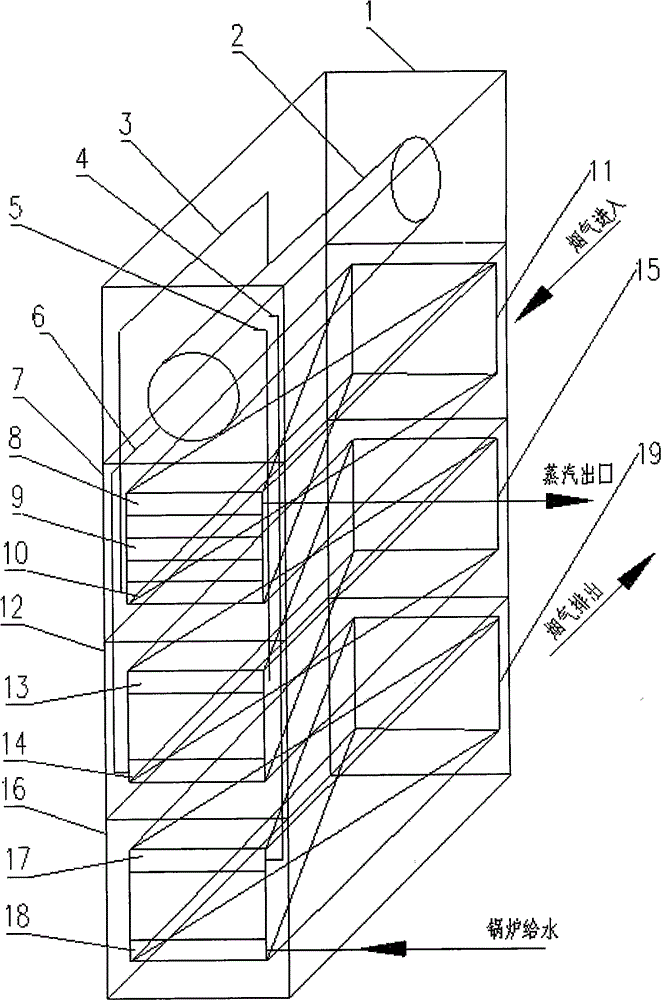

[0012] Below according to the attached figure 1 The present invention is further analyzed.

[0013] A new type of modular vertical water tube waste heat boiler, consisting of a drum box (group) 1, a drum 2, a steam conduit 3, a boiler feed pipe 4, an evaporator rising pipe 5, an evaporator descending pipe 6, and a superheater box Body (group) 7, superheater outlet header 8, desuperheater header 9, superheater inlet header 10, superheated tube bundle and flue 11, evaporator box (group) 12, evaporator upper header 13, Evaporator lower header 14, evaporator tube bundle and flue 15, economizer box (group) 16, economizer upper header 17, economizer lower header 18, economizer tube bundle and flue 19, etc. Composition: Drum box (group) 1 contains boiler drum 2, steam conduit 3, boiler water supply pipe 4, evaporator riser 5, evaporator downpipe 6, safety valve and sewage pipe; the superheater box (Group) 7 contains superheater outlet header 8, desuperheater header 9, superheater i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com