Biomass burning machine provided with tubular furnace hearth

A biomass and burner technology, applied in combustion methods, combustion equipment, combustion of solid fuels, etc., can solve problems such as low pollution and low energy consumption, and achieve the effect of extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

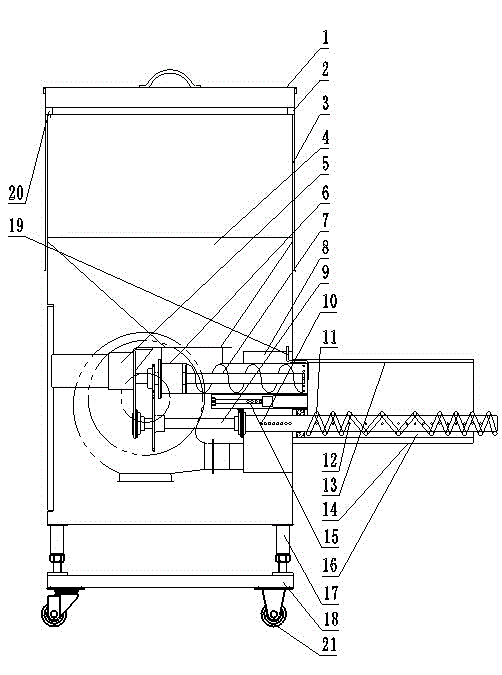

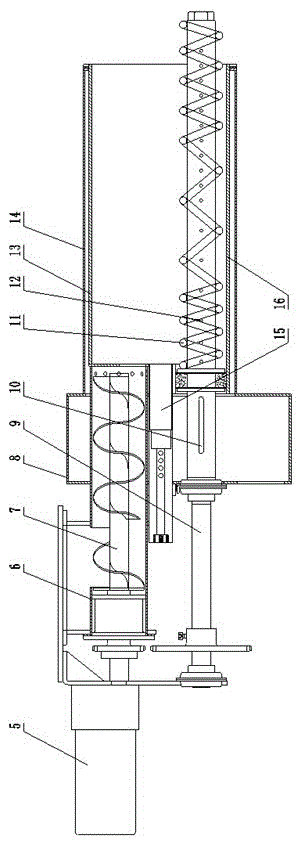

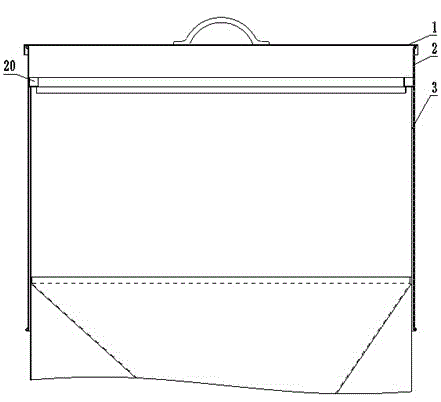

[0035] A tubular furnace biomass burner, consisting of a silo, a feeding mechanism, a tubular furnace, and a slag discharge and slag breaking device. The top of the silo is provided with a detachable elongated cylinder (2), and the silo cover (1) Set on the top of the extended cylinder (2), the cylinder (3) is equipped with a hopper (4); the feeding mechanism includes a feeding shell (6), a feeding screw (7), and a feeding shell (6) Pass through the bellows (8) and moveably install at the outlet at the bottom of the hopper (4). The feed screw (7) is installed in the feed housing (6). The slag discharge device includes a slag discharge device with a hollow part. The slag-breaking screw (9) and the sprocket (10), the front section of the slag-discharging and slag-breaking screw (9) is solid, the middle section and the rear section are hollow, and the middle section is provided with an air inlet hole (10) communicated with the bellows (8). The rear section is provided with spir...

Embodiment 2

[0038] After the tubular furnace biomass burner described in this embodiment is started, the biomass fuel stored in the hopper of the silo enters the feeding shell through the hopper, and is pushed into the bottom of the inner sleeve of the tubular furnace by the feeding screw rod. The feed amount is controlled by the controller. After the initial feed amount is completed, the electronic igniter heats and ignites, and the air from the air supply system enters the tubular furnace through the bellows, and enters the bottom of the inner sleeve after being heated by the electronic igniter to ignite the biomass fuel. , after the biomass fuel is heated, through the primary oxygen supply and secondary oxygen supply of the distribution air system, the bottom drying, combustion, cracking and gasification, low-temperature combustion in the middle section, and high-temperature combustion process in the front section are realized in the inner sleeve, and then its high-temperature flame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com