Efficient novel biomass solid molded fuel combustion apparatus

A technology of solid briquette fuel and combustion device, which is applied in the combustion of solid fuel, air/fuel supply for combustion, combustion method, etc., can solve the problems of reducing the heat production rate of biomass fuel, low heat efficiency, and prolonged combustion time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

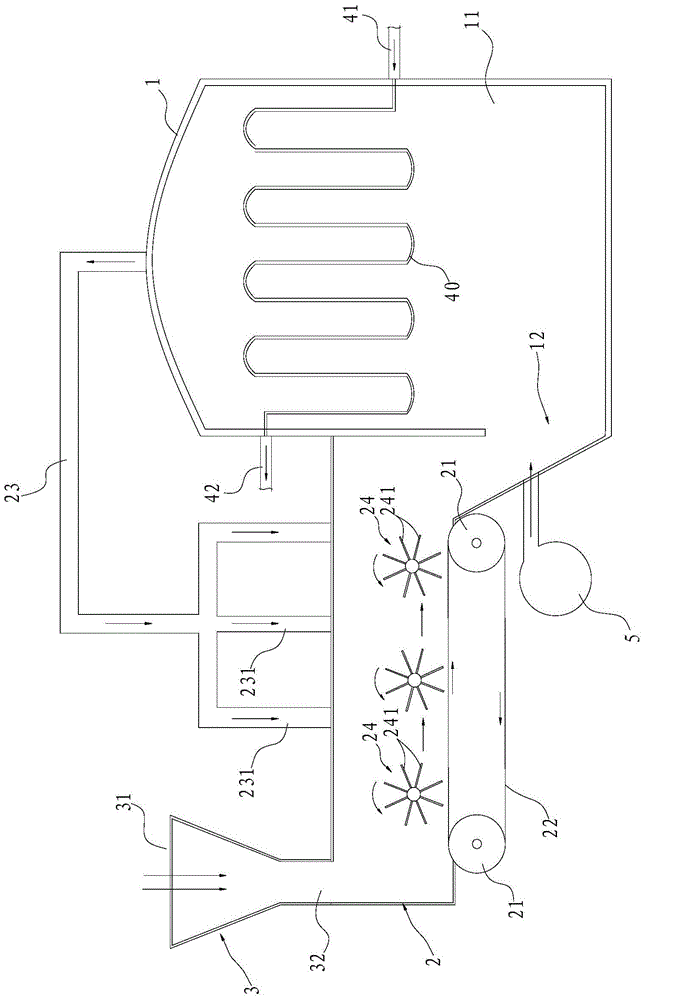

[0016] see figure 1 , which is a new type of high-efficiency biomass solid molding fuel combustion device of the present invention, including a furnace 1, a hopper 3 and a feeding preheating channel 2; the furnace 1 has a combustion chamber 11 inside, and the combustion chamber 11 is equipped with Heat exchange tube 40, one end of the heat exchange tube 40 communicates with the water inlet pipe 41, and the other end is connected to the heat energy output device (not shown in the figure) through the outlet tube 42. The heat exchange tube 40 is a reciprocating and circuitous tubular structure; The water inlet pipe 41 leads into the heat exchange pipe 40, and undergoes sufficient heat exchange with the hot air in the combustion chamber 11 through multiple reciprocating detours. The cold water turns into high-temperature hot steam, and is finally exported f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com