Automatic Separation System and Its Application in Separation of Polar Components of Edible Oil

An automatic separation and full-automatic technology, applied in the direction of material separation, analysis of materials, measuring devices, etc., can solve the problems of separation effect verification lag, unstable results, poor reproducibility, etc., to save manual correction, avoid time and reagents, Strong anti-pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

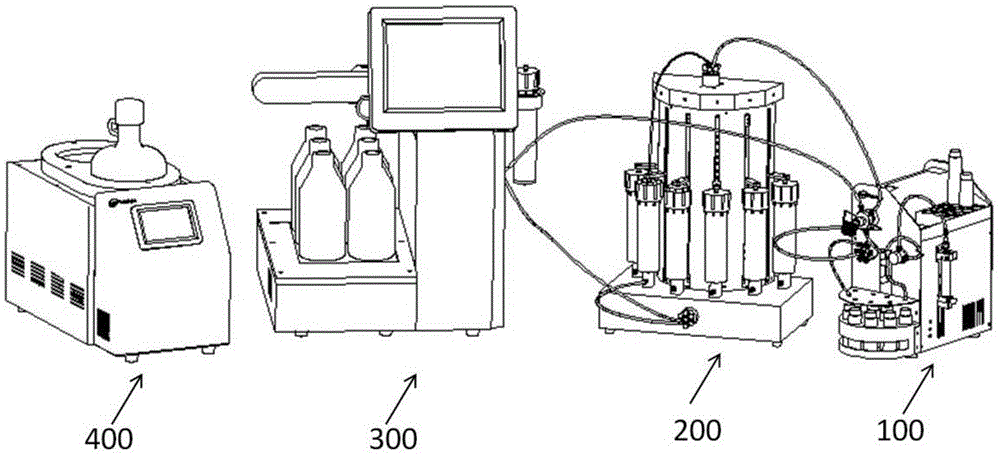

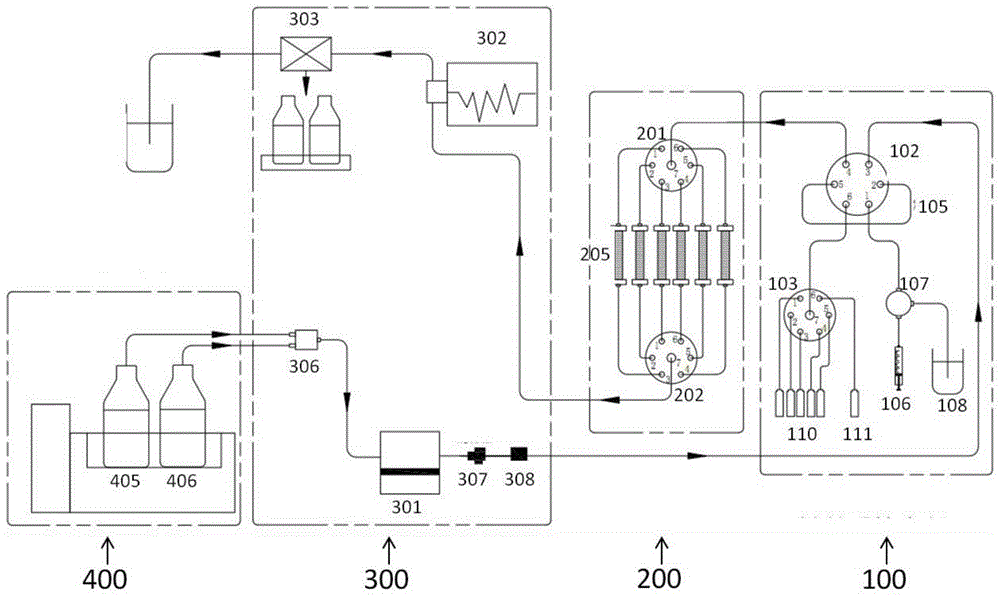

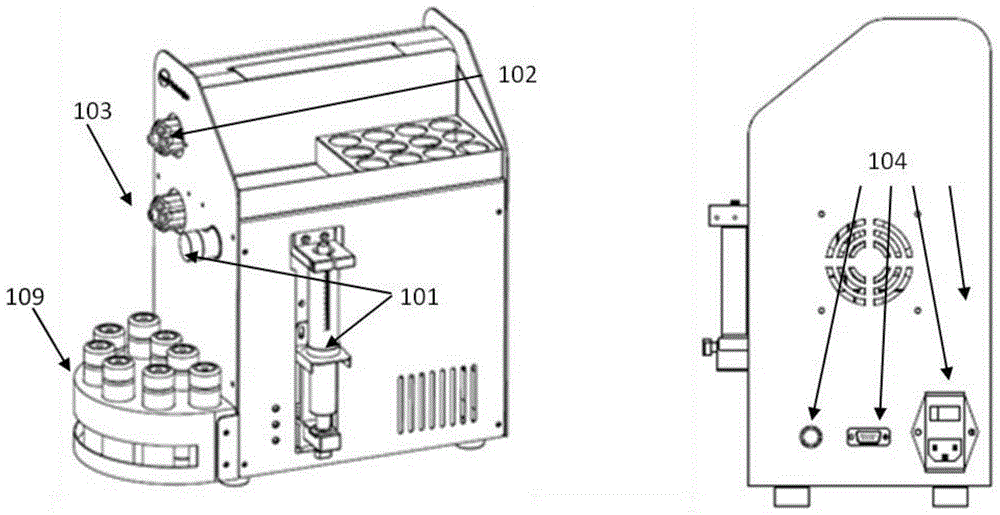

Image

Examples

Embodiment approach

[0097] 1 Sample preparation

[0098] 1.1 Remove impurities

[0099] The sample used as the test sample should be liquid, clear, free of sediment and well mixed. If the sample is not clear and has precipitation, put the oil in a water bath or a constant temperature drying oven at 50°C, heat the oil to 50°C and shake it sufficiently to melt possible oil crystals. If the oil sample becomes clear without precipitation at this time, it can be used as a sample, otherwise, the oil should be placed in a constant temperature drying oven at 50°C, and the insoluble impurities should be filtered with filter paper, and the filtered clear liquid oil should be used as a sample. In order to prevent oil oxidation, the filtration process should be completed as soon as possible.

[0100] For samples with a freezing point higher than 50°C or containing oil components with a freezing point higher than 50°C, the oil must be placed in a water bath or a constant temperature drying oven about 10°C h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com