Product recycling system and online detection method based on full-angle two-dimensional code

A two-dimensional code, full-angle technology, applied in the field of product recycling, can solve problems such as high pipeline risk, and achieve the effect of reducing human factors and high synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

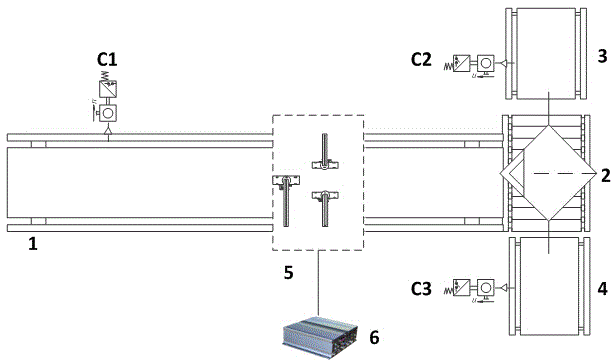

[0024] This embodiment discloses an on-line product reuse system based on full-angle two-dimensional code detection, which includes a product recycling detection conveyor belt 1 for conveying printed two-dimensional code image identification, a product separation device 2, and a product separation device 2 for product The reused normal production main conveyor belt 3, an isolation conveyor belt 4 for conveying abnormal products, one end of the product separation device 2 is connected to the normal production main conveyor belt 3 and the isolation conveyor belt 4, and the other end of the product separation device is connected to the product recovery detection conveyor belt 1. The inflow end of the recovery detection conveyor belt 1 is provided with a sensor C1 for counting, the inflow end of the normal production main conveyor belt 3 is provided with a sensor C2 for counting, and the inflow end of the isolation conveyor belt 4 is provided with a sensor C3 for counting. The serv...

Embodiment 2

[0040] Taking the recycling of ice dew mineral water bottles (big bottles) in beverage factories as an example, the specific implementation process of the present invention is specifically described:

[0041] Install an assembly line product reuse system based on full-angle two-dimensional code detection in a beverage factory. The specific method of use includes production line transformation steps and production control steps.

[0042] The production line transformation steps include adding a product recycling detection conveyor belt printed with a QR code image logo, a product separation device, an original owner conveyor belt for product reuse, and an isolation conveyor belt for conveying abnormal products.

[0043] Recycling detection conveyor belt: used to detect whether the product QR code image information is normal, and communicate and cooperate with the separation device;

[0044] Separation device: used to separate and recover the normal and abnormal product queues, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com