Three dimension (3D) printing method for multilayer flexible circuit board

A flexible circuit board and 3D printing technology, which is applied in multilayer circuit manufacturing, printed circuit, printed circuit manufacturing, etc., can solve problems such as the production disadvantages of multilayer flexible circuit boards, and achieve low production costs, high precision, and simple processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

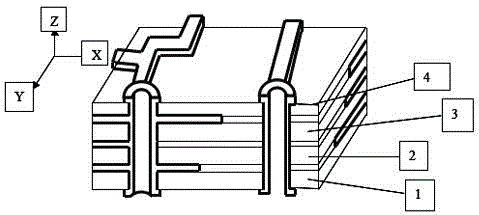

[0015] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail in conjunction with the accompanying drawings.

[0016] The invention relates to a 3D printing method of a multilayer flexible circuit board, which is carried out according to the following steps:

[0017] 1) Provide the substrate material, which is composed of polyimide powder, polyester powder and acrylic UV shadowless glue; the materials provided as the metal conductor part are copper powder, cobalt-chromium alloy powder, gold powder and silver powder. ;

[0018] 2) Printing starts from the bottom circuit board of the multi-layer flexible circuit board, and prints each layer obtained by cutting layer by layer according to the 3D CAD model in a specific direction. The printing direction of each layer is first the x-axis direction and then the y-axis direction , the printing starting point is the vertex i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com