Crude oil electric desalting process

An electric desalination and crude oil technology, which is applied in the petroleum industry, electric/magnetic dehydration/emulsification, and hydrocarbon oil treatment, can solve the problems of high power consumption, long crude oil residence time, poor running stability, etc., and achieve power saving , save the residence time, the effect of smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

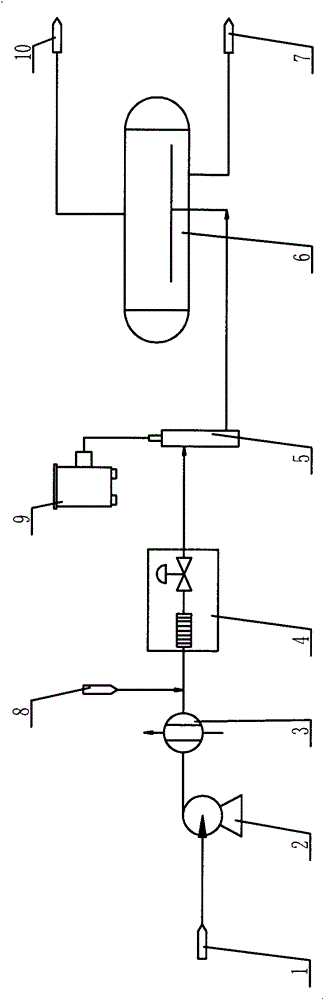

[0030] as attached figure 1 , using a first-stage electric desalination process, a pipeline demulsifier 5. Crude oil desalting process is as follows: raw material oil 1 enters heat exchanger 3 through crude oil pump 2 for heat exchange to about 100-160 °C, demulsifier and washing water 8 are mixed with heat exchanged raw material oil through mixing equipment 4, so that The washing water is dispersed in the crude oil to form water droplets with a diameter of about 10 microns, and through contact with the salt in the crude oil, the salt in the crude oil is dissolved in the washing water, and the mixed crude oil enters the upper part of the pipeline type demulsifier 5, and the transformer 9 Supply power to the internal electrodes of pipeline-type demulsifier 5 to form a high-voltage electrostatic field for demulsification treatment. The diameter of water droplets in the emulsion after demulsification increases from 10 microns to about 100-300 microns, and the demulsified crude oi...

Embodiment 2

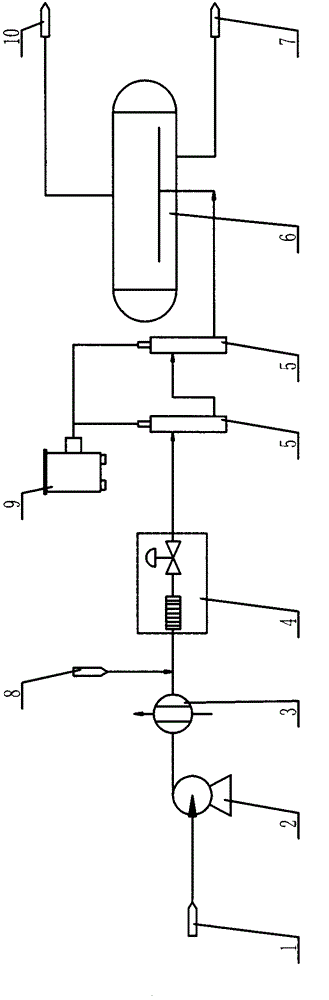

[0034] as attached figure 2 , using a first-stage electric desalination process, two pipeline demulsifiers 5. Crude oil desalination process is as follows: raw oil 1 enters heat exchanger 3 through crude oil pump 2 for heat exchange to about 100-160°C, demulsifier and washing water 8 are mixed with heat exchanged raw oil through mixing equipment 4, mixed The final crude oil enters the upper part of the first pipeline-type demulsifier 5, and the transformer 9 supplies power to the internal electrodes of the first pipeline-type demulsifier 5 to form a high-voltage electrostatic field to perform a demulsification treatment. The bottom of one demulsifier 5 flows out and then enters the upper part of the second pipeline demulsifier, and the transformer 9 supplies power to the internal electrodes of the second pipeline demulsifier 5 to form a high-voltage electrostatic field for secondary demulsification treatment. The crude oil after the first demulsification flows out from the b...

Embodiment 3

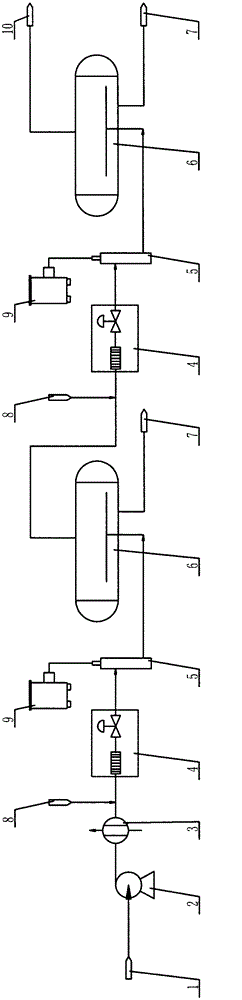

[0038] as attached image 3 , a two-stage electric desalination process is adopted, and a pipeline type demulsifier 5 is used in each electric desalination process. Crude oil desalting process is as follows: raw material oil 1 passes through crude oil pump 2 and enters heat exchanger 3 for heat exchange to about 100-160°C, and then enters the first stage electric desalting process, that is, demulsifier and washing water 8 and raw material after heat exchange The oil is mixed through the mixing equipment 4, and the mixed crude oil enters the upper part of the pipeline-type demulsifier 5, and the transformer 9 supplies power to the internal electrodes of the pipeline-type demulsifier 5 to form a high-voltage electrostatic field. The crude oil flows out from the bottom of the pipeline type demulsifier 5 and then enters the bottom of the settling tank 6, where oil-water separation is carried out in the settling tank 6, the separated water 7 flows out from the bottom of the settlin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com