Multiple-tube-core electronic direct-writing ballpoint pen

A ballpoint pen and multi-die technology, applied in circuits, electrical components, printed circuits, etc., can solve the problems of high material and energy consumption, complex circuit or electronic device manufacturing procedures, and high environmental pollution, and achieve energy consumption and material invalid loss. Low, reduced complexity and cost, increased productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

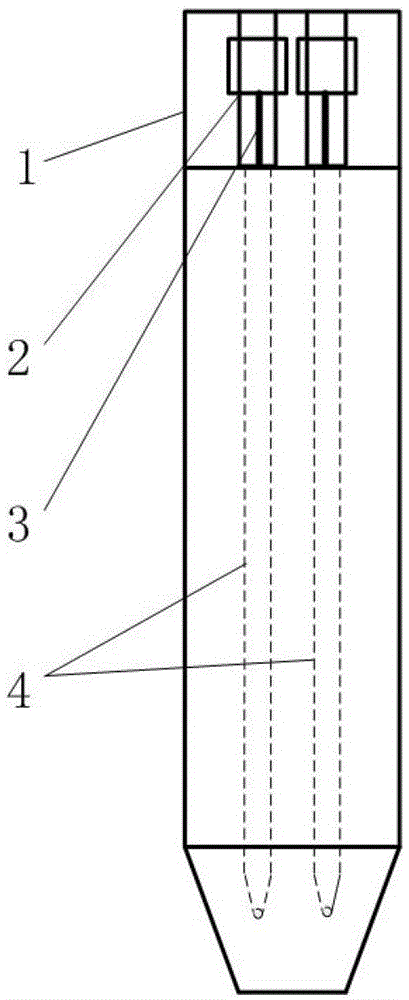

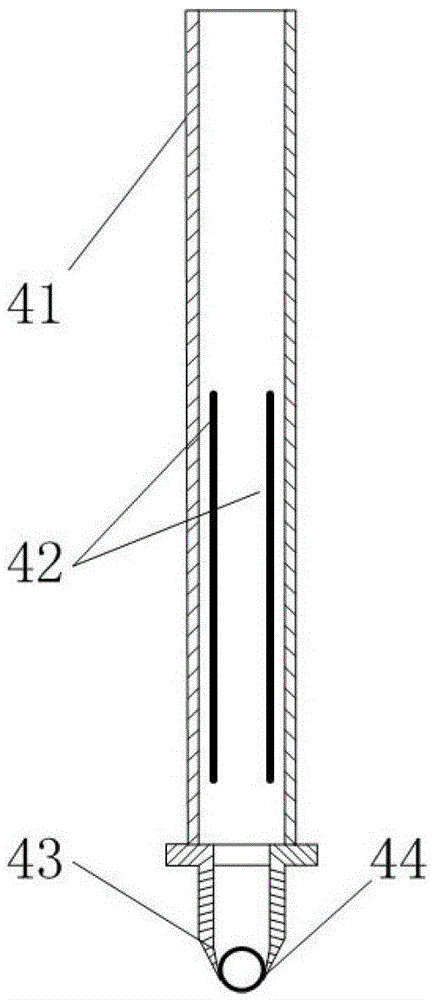

[0024] Such as figure 1 and figure 2 As shown, the multi-core electronic direct-writing ballpoint pen according to the embodiment of the present invention includes a pen holder structure and a refill 4 loaded with different inks.

[0025] Wherein, the pen holder structure includes: a pen case 1 , a pen core button 2 and a pen core spring 3 .

[0026] The pen case 1 is used for packaging and carrying the refill button 2, the refill spring 3 and the refill 4. The pen case 1 can be used for carrying components and 1-50 refills filled with ink. figure 2 The pen shell 1 shown in the figure carries components and four pen refills 4, which are respectively loaded with liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com