Circuit board and manufacturing method thereof

A manufacturing method and circuit board technology, applied in the directions of printed circuits, printed circuits, circuit devices, etc., can solve the problems of increased circuit board time, high circuit board production costs, easy to be scrapped, etc., to prevent electromagnetic interference and reduce manufacturing costs. , the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The circuit board provided by the technical solution and its manufacturing method will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0017] The manufacturing method of the circuit board provided by the embodiment of the technical solution includes the following steps:

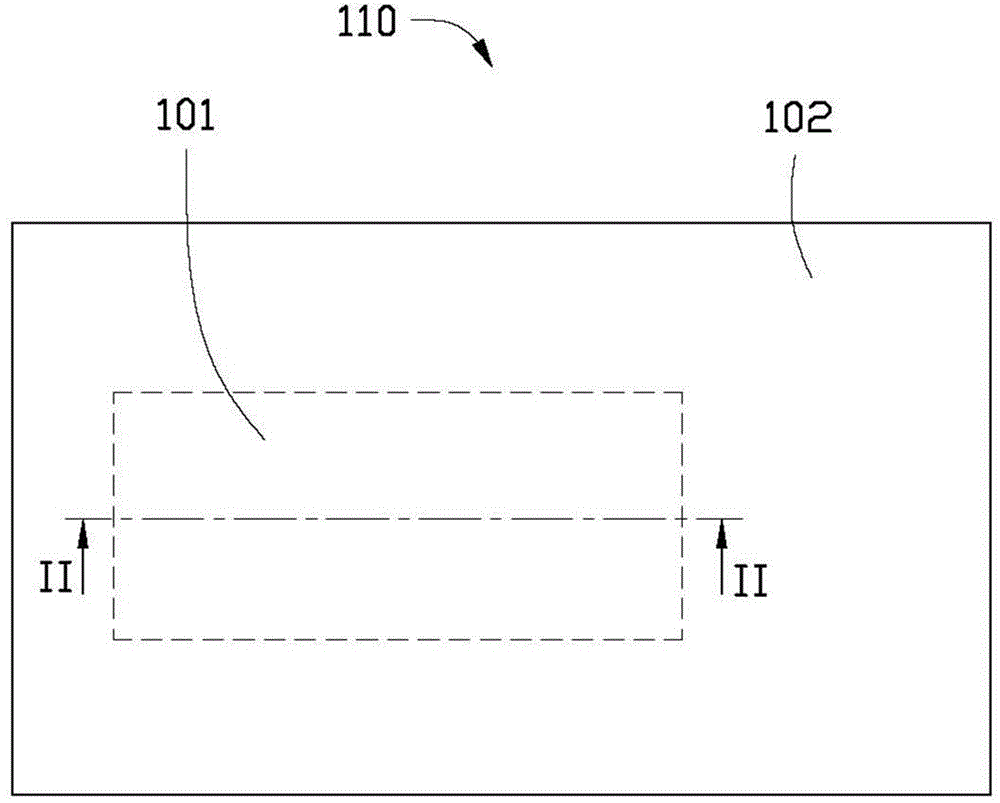

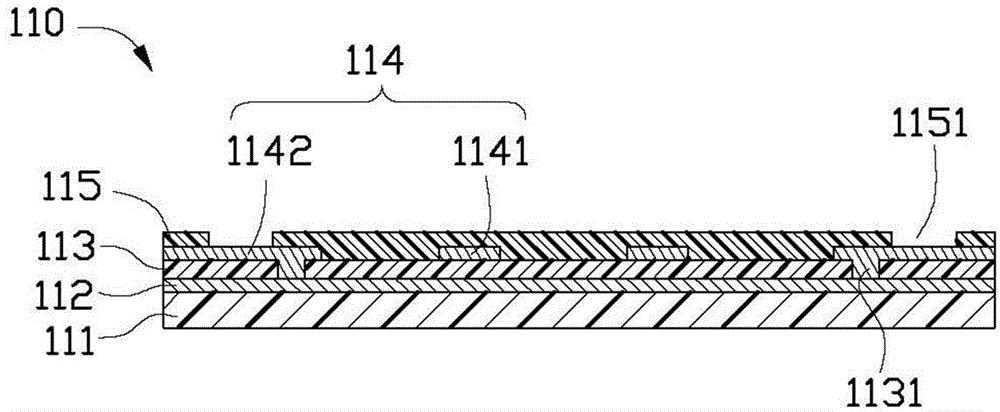

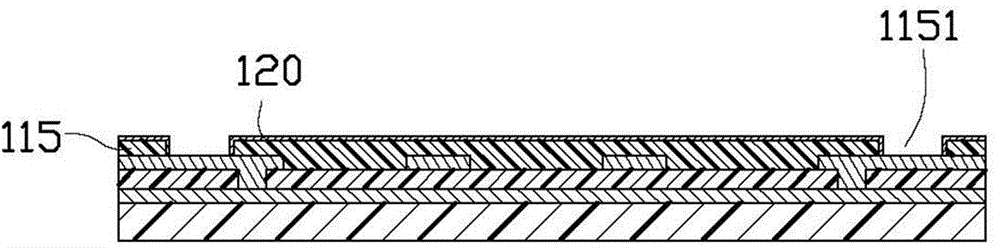

[0018] For the first step, please also refer to figure 1 and figure 2 , providing a circuit substrate 110 .

[0019] In this embodiment, the circuit substrate 110 is a circuit board with conductive lines formed thereon. The circuit substrate 110 includes a first insulating layer 111 , a grounding conductive layer 112 , a second insulating layer 113 , a conductive circuit layer 114 and a third insulating layer 115 arranged in sequence.

[0020] The circuit substrate 110 has an electromagnetic shielding forming area 101 and a common area 102 except the electromagnetic shielding forming area 101 , and the electromagnetic shielding forming area 101 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com