Tartary buckwheat white tea and processing technology thereof

A technology of tartary buckwheat white tea and tartary buckwheat is applied in the direction of tea substitutes, etc., which can solve problems such as unsatisfactory effects, and achieve the effects of enhancing human immunity, improving human immunity, and detoxifying effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

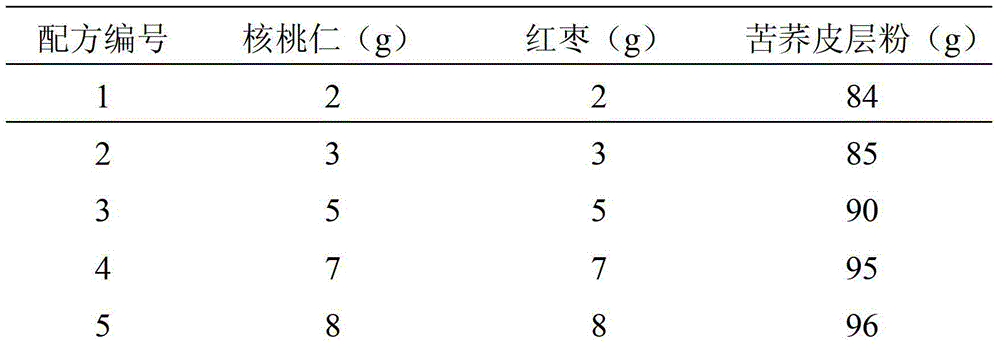

[0116] formula:

[0117] 3kg of walnut kernels, 3kg of red dates, and 85kg of tartary buckwheat powder.

[0118] Process:

[0119] (1) Superfinely pulverize each raw material:

[0120] Get the walnut kernels and red dates, dry them separately, superfinely pulverize them, pass through a 300-mesh sieve, and set aside; take tartary buckwheat cortex powder, superfinely pulverize them, pass through a 300-mesh sieve, and set aside;

[0121] (2) Mix evenly according to the proportion:

[0122] After the walnut kernel superfine powder and red date superfine powder and tartary buckwheat layer powder superfine powder are mixed uniformly by the proportioning of kg, add the water that weight is 30% of raw material gross weight, stir into soft material, the dry material of soft material The degree of wetness is determined by the degree that the hands can form a ball without sticking to the hand and can be cracked with light pressure with fingers;

[0123] (3) Extrusion granulation:

...

Embodiment 2

[0132] formula:

[0133] 4kg of walnut kernels, 4kg of red dates, and 87.5kg of tartary buckwheat powder.

[0134] Process:

[0135] (1) Superfinely pulverize each raw material:

[0136] Get the walnut kernels and red dates, dry them separately, superfinely pulverize them, pass through a 300-mesh sieve, and set aside; take tartary buckwheat cortex powder, superfinely pulverize them, pass through a 300-mesh sieve, and set aside;

[0137] (2) Mix evenly according to the proportion:

[0138] After the walnut kernel superfine powder and the red date superfine powder and the tartary buckwheat layer powder superfine powder are mixed evenly according to the kg proportioning, add the water with a weight of 31.25% of the total weight of the raw materials, stir into a soft material, and the dry material of the soft material The degree of wetness is determined by the degree that the hands can form a ball without sticking to the hand and can be cracked with light pressure with fingers;...

Embodiment 3

[0148] formula:

[0149] 5kg of walnut kernels, 5kg of red dates, and 90kg of tartary buckwheat powder.

[0150] Process:

[0151] (1) Superfinely pulverize each raw material:

[0152] Get the walnut kernels and red dates, dry them separately, superfinely pulverize them, pass through a 400-mesh sieve, and set aside; take tartary buckwheat cortex powder, superfinely pulverize them, pass through a 400-mesh sieve, and set aside;

[0153] (2) Mix evenly according to the proportion:

[0154] After mixing evenly the walnut kernel superfine powder and red date superfine powder and tartary buckwheat layer powder superfine powder of step (1) gained by kg proportioning, add the water that weight is 32.5% of raw material gross weight, stir into soft material, the dry material of soft material The degree of wetness is determined by the degree that the hands can form a ball without sticking to the hand and can be cracked with light pressure with fingers;

[0155] (3) Extrusion granulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com