A method for preparing mulberry superfine powder by using differential pressure blasting pretreatment technology

An ultrafine powder and pretreatment technology, which is applied in the field of food processing, can solve the problems of destroying the nutritional content of products, immature subsequent permeate treatment technology, and expensive production equipment, so as to improve production efficiency and quality, avoid thermal degradation, and save energy. Effect of drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

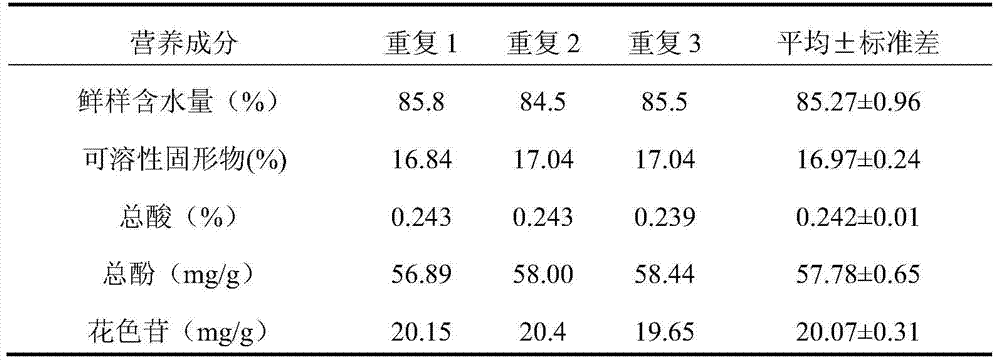

[0045] In this embodiment, the ultrafine powder of mulberry is prepared by pressure differential blasting pretreatment combined with convective infrared combined drying technology, including the following steps:

[0046] (1) selection: select 500g of mulberries that are complete, without mechanical damage, and without spoilage;

[0047] (2) Cleaning: wash twice with tap water and drain;

[0048] (3) Differential pressure blasting: put the mulberries into a blasting tank with a temperature of 100°C, keep warm for 10 minutes, open the vacuum valve to vacuumize the blasting tank to instantly drop the vacuum degree to -0.1MPa, and let the mulberry fruit be vacuumed Place it in the final container for 3 minutes, then close the vacuum valve and release the vacuum in the explosion tank; the pressure differential explosion is carried out once;

[0049] (4) Drying: Put the mulberries obtained in step (3) into the convection infrared combined drying equipment. In the early stage of dry...

Embodiment 2

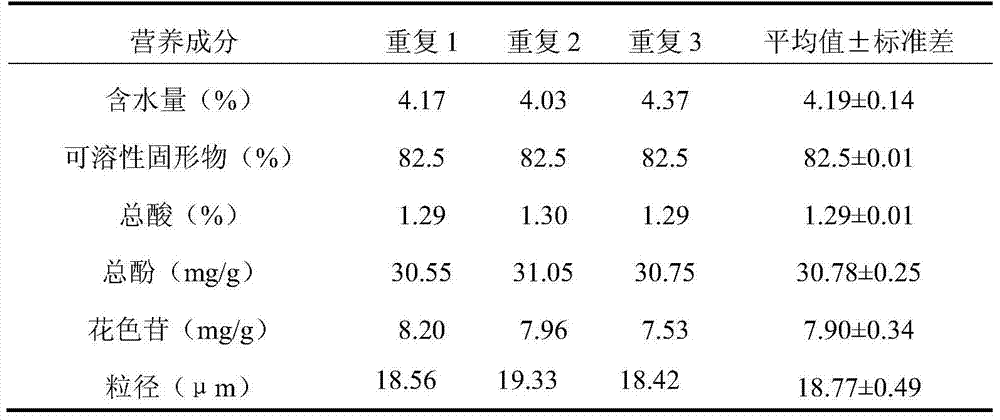

[0060] The present invention utilizes pressure difference blasting pretreatment combined with convection infrared combined drying technology to prepare mulberry superfine powder, comprising the following steps:

[0061] (1) selection: select 500g of mulberries that are complete, without mechanical damage, and without spoilage;

[0062] (2) Cleaning: Wash twice with tap water and drain.

[0063] (3) Differential pressure blasting: put the mulberries into a blast tank with a temperature of 110°C, keep warm for 15 minutes, open the vacuum valve to vacuumize to form a vacuum of -0.1MPa, and let the mulberries be placed in the vacuumized container for 4 minutes , then close the vacuum valve and let off the vacuum in the explosion tank; the pressure differential explosion is carried out 3 times;

[0064] (4) Drying: Put the mulberries obtained in step (3) into the convection-infrared combined drying equipment. In the early stage of drying, convective drying and infrared radiation a...

Embodiment 3

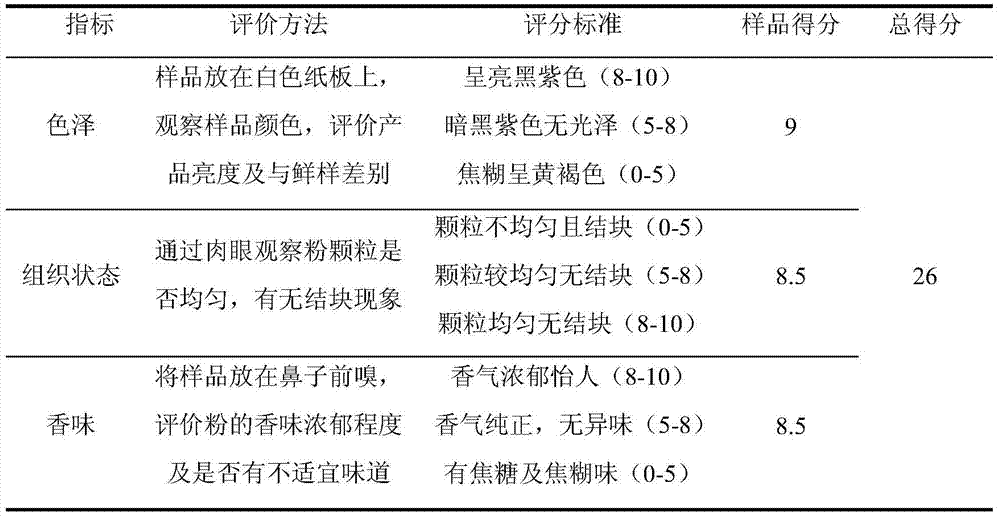

[0075] The present invention utilizes pressure difference blasting pretreatment combined with convection infrared combined drying technology to prepare mulberry superfine powder, comprising the following steps:

[0076] (1) selection: select 500g of mulberries that are complete, without mechanical damage, and without spoilage;

[0077] (2) Cleaning: wash twice with tap water and drain;

[0078] (3) Differential pressure blasting: Put the mulberries into a blast tank with a temperature of 95°C, keep warm for 20 minutes, open the vacuum valve to vacuumize to form a vacuum of -0.1MPa, and let the mulberries be placed in the vacuumized container for 5 minutes , then close the vacuum valve and let off the vacuum in the explosion tank; the pressure differential explosion is carried out 5 times;

[0079] (4) Drying: Put the mulberries obtained in step (3) into the convection infrared combined drying equipment. In the early stage of drying, convective drying and infrared radiation ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com