Anti-pollution polyamide composite membrane and preparation method thereof

An anti-pollution, polyamide technology, applied in the field of water treatment, can solve problems such as affecting the membrane surface potential and hydrophilicity, decreasing the separation performance of the composite membrane, reducing the mechanical properties of the membrane, etc., achieving good microbial resistance and anti-pollution performance, Microbial resistance and anti-pollution performance, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] An anti-pollution polyamide composite membrane, comprising a non-woven fabric layer, a polysulfone support layer, a polyamide layer and an anti-pollution layer arranged in sequence, the anti-pollution layer contains a broad-spectrum antibacterial agent containing a hydroxyalkyl group, a hydrophilic A cross-linked polymer obtained by carrying out a cross-linking reaction between a permanent polymer and a cross-linking agent in the presence of water and a catalyst, wherein the cross-linking reaction refers to two or more molecules (usually linear molecules) bonded to each other and cross-linked The relatively stable molecules (body-shaped molecules) forming a network structure react; the thickness of the polyamide layer is 50-300nm, and the thickness of the anti-pollution layer is 20-200nm.

[0042] The broad-spectrum antibacterial agent that contains hydroxyalkyl group selects 5-amino-1-hydroxyethylpyrazole for use, and its content is 0.1% (the content of broad-spectrum a...

Embodiment 2

[0057] A kind of antipollution polyamide composite membrane, differs from embodiment 1 in that:

[0058] The broad-spectrum antibacterial agent containing hydroxyalkyl is selected from 4,5-diamino-1-(2-hydroxyethyl)pyrazole.

[0059] Table 1 shows the results obtained by testing the above polyamide composite membrane.

[0060] The structural formula of the cross-linked polymer obtained by cross-linking the above-mentioned broad-spectrum antibacterial agent, hydrophilic polymer and cross-linking agent is as follows:

[0061]

[0062] Where m+n=1, m>0, n>0.

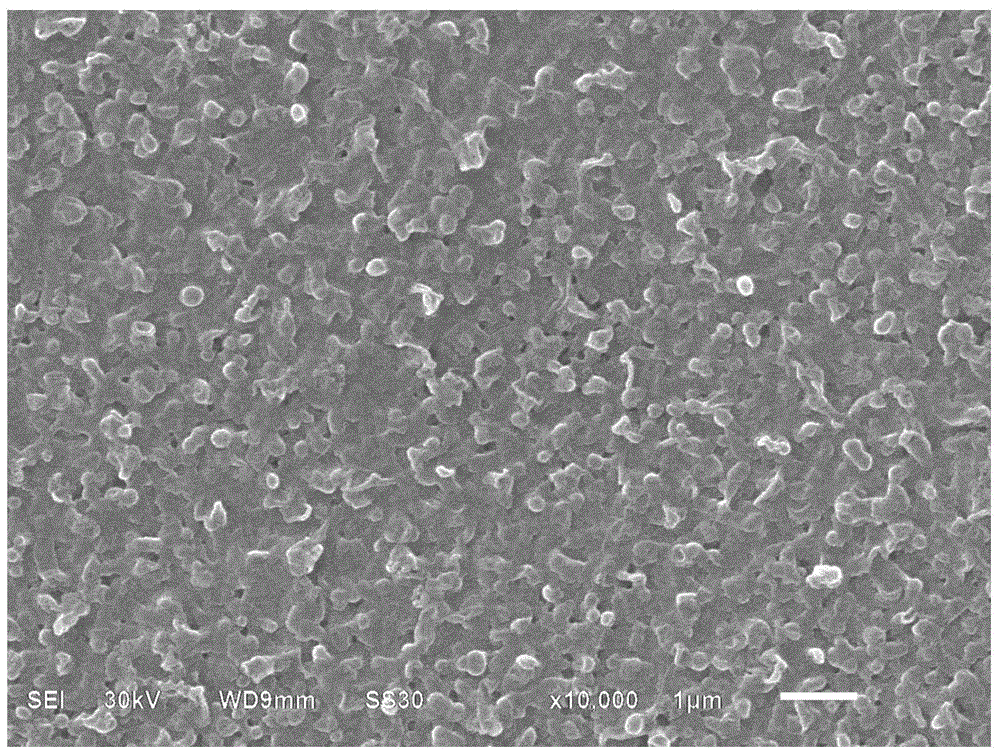

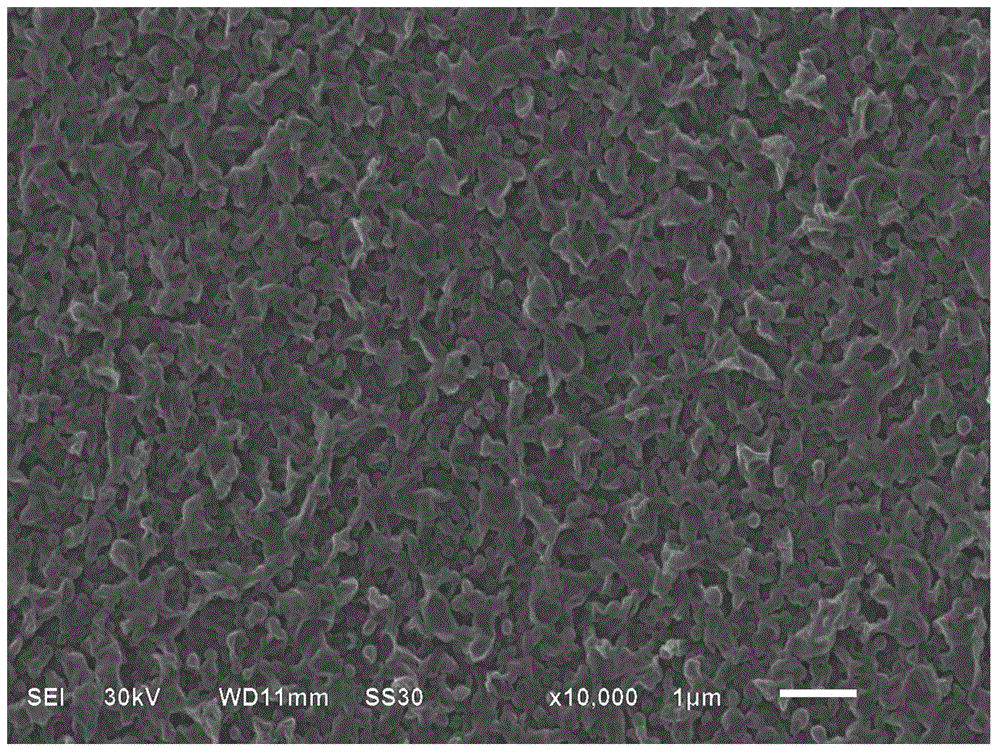

[0063] The surface of the anti-pollution polyamide composite membrane of the present invention (Example 2) is thicker and smoother than the surface of the traditional polyamide composite membrane (comparative example), and is more scratch-resistant and pollution-resistant.

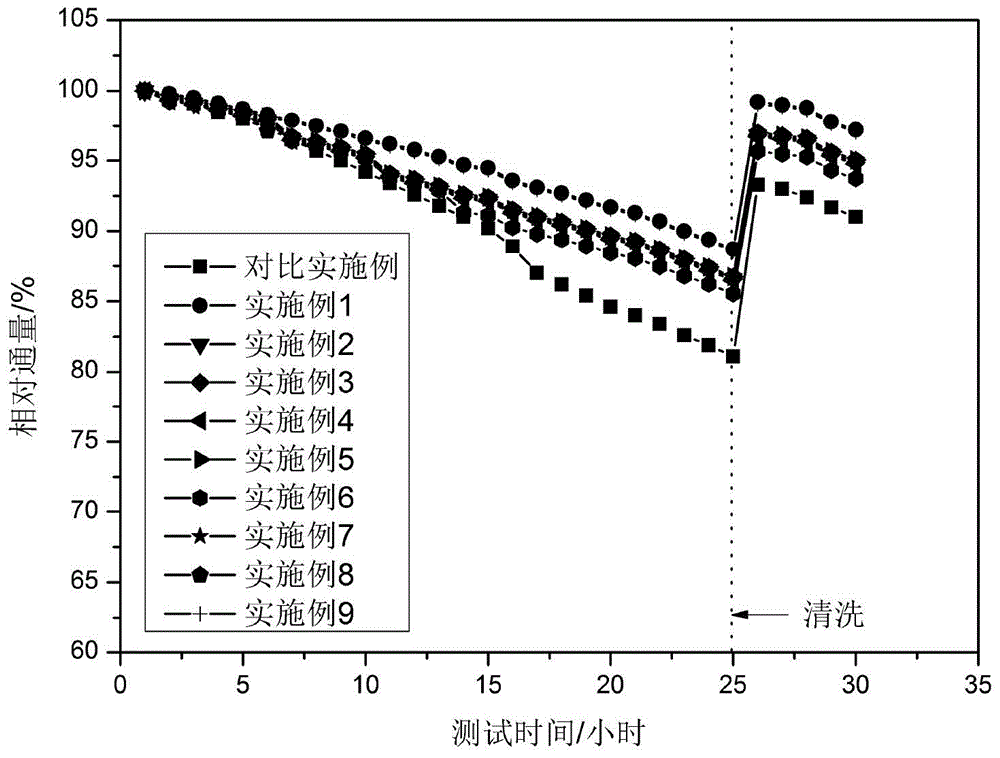

[0064] Conventional polyamide composite membrane (comparative example) and gained polyamide composite membrane of the present invention (embodimen...

Embodiment 3

[0066] An anti-pollution polyamide composite membrane, which differs from Example 1 in that: 1,3-dimethylol-5,5-dimethylhydantoin is selected as the broad-spectrum antibacterial agent containing hydroxyalkyl groups.

[0067] Table 1 shows the results obtained by testing the above polyamide composite membrane. The structural formula of the cross-linked polymer obtained by cross-linking the above-mentioned broad-spectrum antibacterial agent, hydrophilic polymer and cross-linking agent is as follows:

[0068]

[0069] Where m+n=1, m>0, n>0.

[0070] The surface of the anti-pollution polyamide composite membrane of the present invention (Example 3) is thicker and smoother than the surface of the traditional polyamide composite membrane (comparative example), and is more scratch-resistant and pollution-resistant.

[0071] Conventional polyamide composite membrane (comparative example) and gained polyamide composite membrane of the present invention (embodiment 3) use the attenu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com