Zinc stearate granulating process and equipment

A technology of zinc stearate and granulation equipment, which is applied in the direction of liquid separation into bead droplets and granulation, can solve the problems that the particle size of powder products is difficult to control, the requirements for mixing and dispersing technology are high, and the grinding cost is high. Excellent performance, convenient for accurate measurement, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

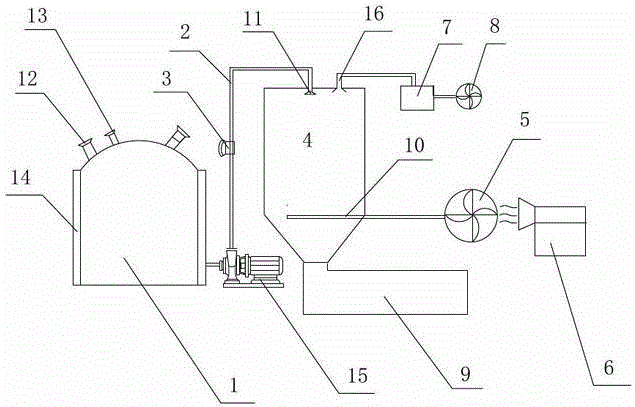

[0031] refer to figure 1 A kind of Zinc stearate granulation equipment, comprises reactor 1, conveying pipeline 2 and shower head 11 connected successively, and described shower head 11 is positioned at collection box 4 tops, is provided with the cold wind pipe 10 that upward blows cold wind near collection box 4 bottoms , the cold air pipe 10 is connected to the cooling fan 11, and the cooling fan 11 is connected to the humidifier 6; the bottom of the collection box is connected to the oven. The top of the collection box 4 is also provided with a dust discharge pipe 16 , the dust discharge pipe 16 is connected to the dust collection chamber 7 outwardly, and the dust collection chamber 7 is connected to the fan 8 . The feeding pipeline 2 between the reaction kettle 1 and the collection box 4 is provided with a booster pump 15 for providing feeding power. The delivery pipeline 2 is provided with a regulating valve 3 . The reaction kettle 1 is covered with a heating pipe 14 f...

Embodiment 2

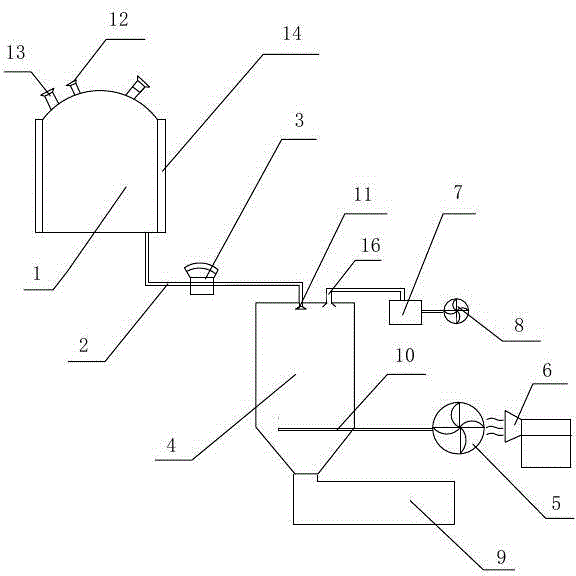

[0034] refer to figure 2 A kind of Zinc stearate granulation equipment, comprises reactor 1, conveying pipeline 2 and shower head 11 connected successively, and described shower head 11 is positioned at collection box 4 tops, is provided with the cold wind pipe 10 that upward blows cold wind near collection box 4 bottoms , the cold air pipe 10 is connected to the cooling fan 11, and the cooling fan 11 is connected to the humidifier 6; the bottom of the collection box is connected to the oven. The top of the collection box 4 is also provided with a dust discharge pipe 16 , the dust discharge pipe 16 is connected to the dust collection chamber 7 outwardly, and the dust collection chamber 7 is connected to the fan 8 . The reactor 1 is positioned higher than the collection box 4, and the molten zinc stearate in the reactor 1 reaches the nozzle 11 through the conveying pipeline 2 by its own gravity. The delivery pipeline 2 is provided with a regulating valve 3 . The reaction ket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com