Coating device and method for teflon tank

A technology of Teflon tank body and coating equipment, which is applied to the device for coating liquid on the surface, coating, surface pretreatment, etc., can solve the problems of low work efficiency, poor coating, troublesome coating inspection, etc. Achieve the effect of improving work efficiency, stable properties and uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the drawings and examples.

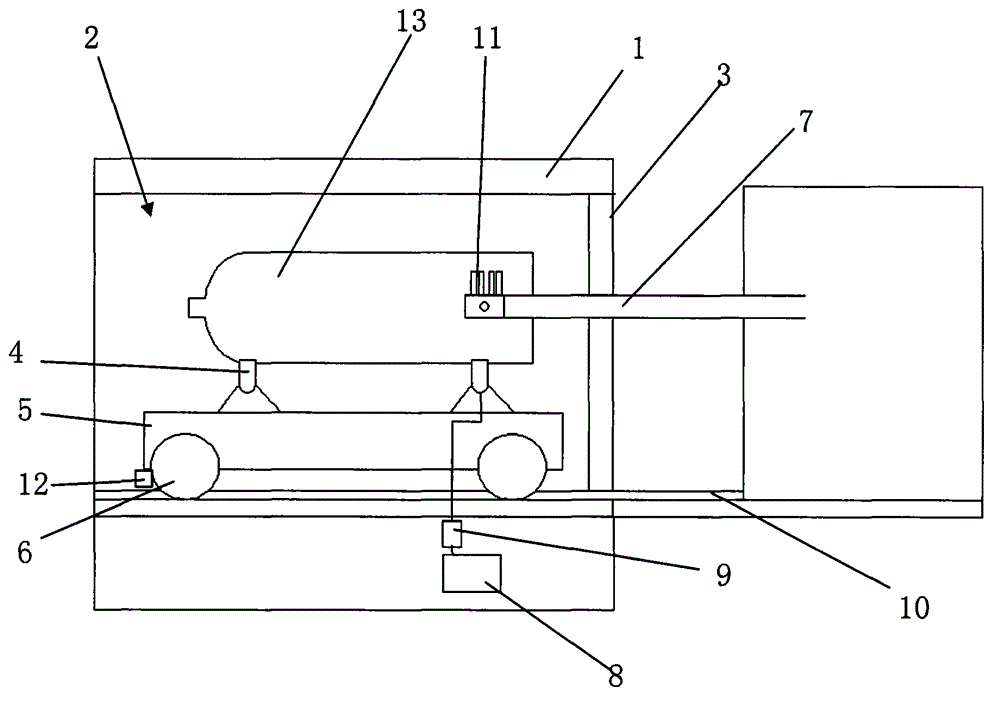

[0023] figure 1 It is a schematic diagram of the Teflon tank body coating equipment utilizing the present invention.

[0024] Such as figure 1 As shown, the Teflon tank coating equipment of the present invention comprises: a curing furnace 1, which forms an airtight furnace cavity 2 inside to form a Teflon coating and curing environment for the tank body 13, and one end of the curing furnace is provided with a selective opening Closed furnace door 3; trolley, which constitutes the supporting structure of the tank body, includes bracket 4, platform 5 and wheels 6 from top to bottom, the wheels are installed below the platform, and the tank body is placed on the bracket, and the trolley carries the tank body The furnace door enters and exits the furnace cavity; the coating gun 7 is set in the curing furnace and extends into the inside of the tank body, and the paint po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com