Dry-process rotary cement kiln cooperative household garbage treatment system and treatment method

A technology of domestic waste and co-processing, applied in the removal of solid waste, etc., can solve the problems of low calorific value, large amount of flue gas, poor stability, etc., and achieve the effect of reducing production cost, saving water resources and avoiding pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The content of the present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments, and the present invention will be further elaborated, but these embodiments in no way limit the present invention. Any changes made by those skilled in the art to the embodiments of the present invention under the inspiration of this specification shall fall within the scope of the claims of the present invention.

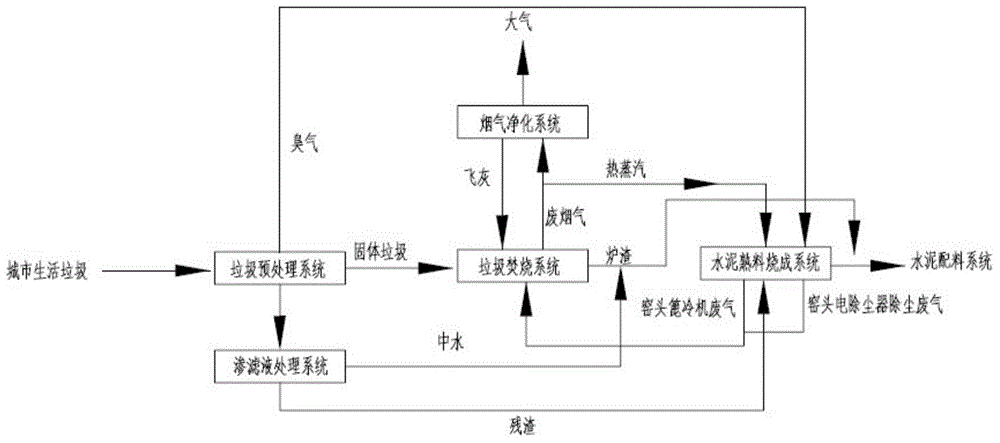

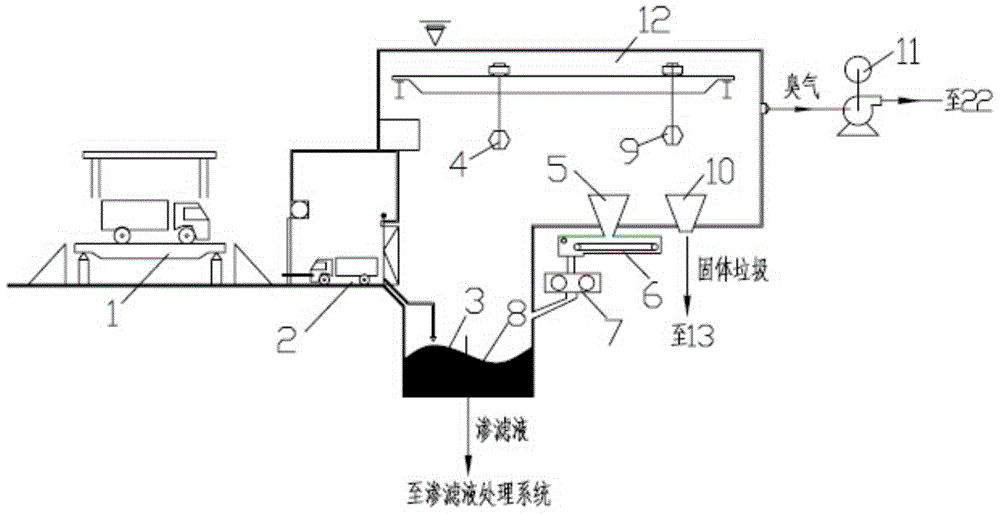

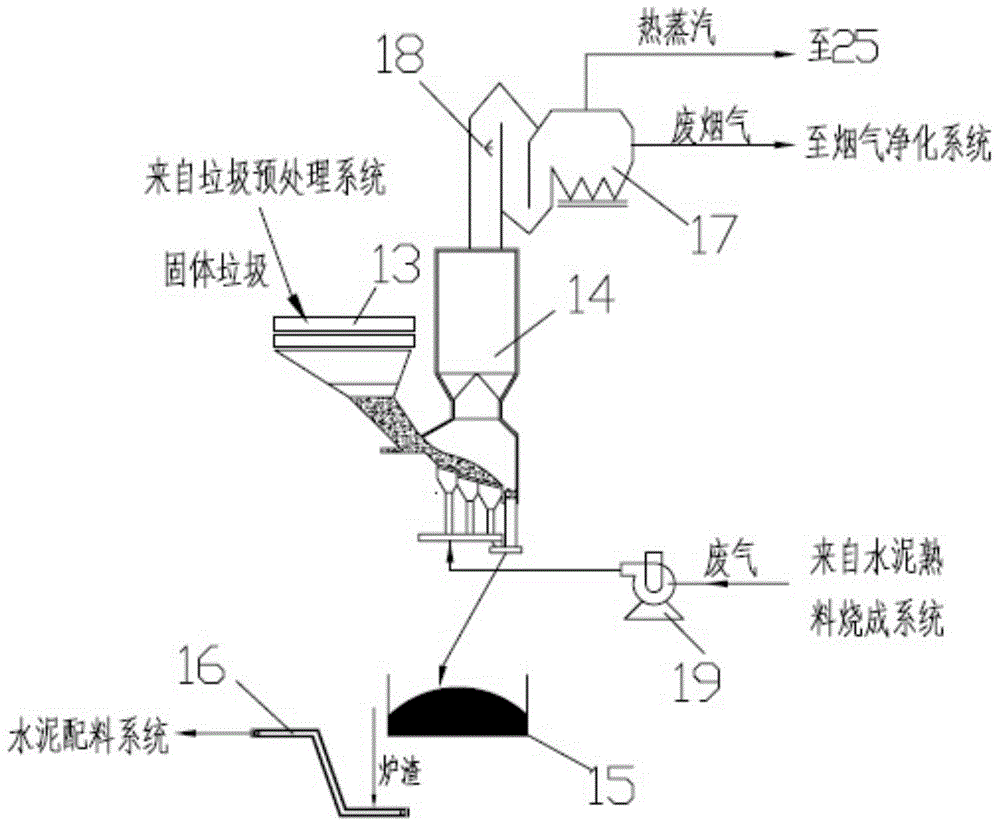

[0052] The dry-process cement rotary kiln cooperative processing domestic waste system provided by the present invention, such as figure 1 As shown, it includes garbage pretreatment system, garbage incineration system, flue gas purification system, leachate treatment system, cement clinker burning system and cement batching system. Among them, the garbage pretreatment system is used for the storage and crushing of domestic garbage. The garbage outlet of the system is connected with the garbage inlet of the garbag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com