Method for forming metalized pattern using jet printing and molded interconnected assembly thereof

A technology of metallization patterns and jet printing, which is applied in chemical instruments and methods, metal layered products, replication/marking methods, etc., can solve the problems of lack of precious metal catalyst inks, etc., and achieve uniform noble metal catalyst layers, large surface area, and increased activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The following are examples, but the contents of the present invention are not limited to the scope of these examples.

[0064] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description with reference to the drawings and embodiments.

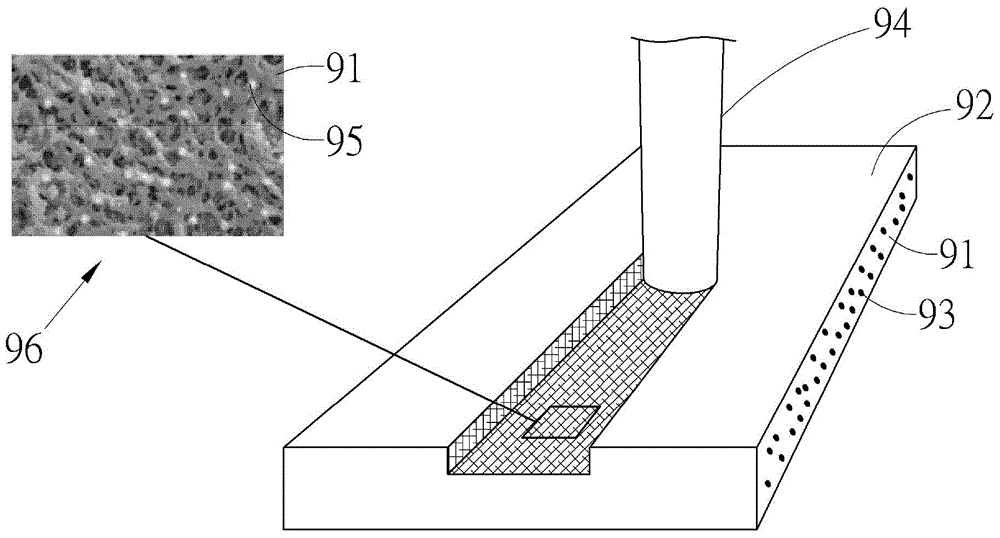

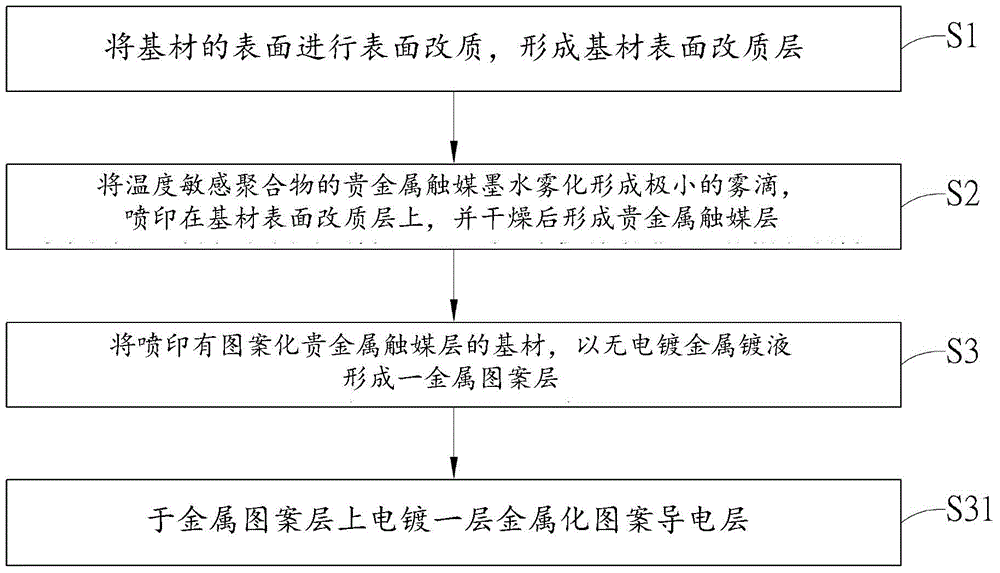

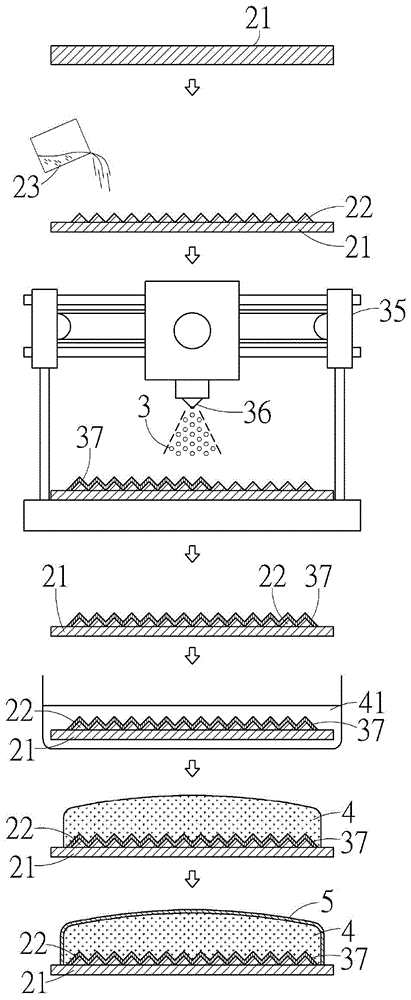

[0065] See figure 2 and 3 , figure 2 It is a step diagram of the method for forming a metallized pattern by jet printing in the present invention, image 3It is a schematic diagram of the method of forming a metallized pattern by spray printing in the present invention. The method of the present invention is to cover the plastic, glass or ceramic plastic mold component 2 substrate 21 with a patterned metal pattern with good adhesion and stability. layer 4, or further form a conductive layer 5 on the metal pattern layer 4 to make a metallized pattern molded interconnection component 1; wherein, when the material of the base material sel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com