Preparation method of hollow silicon dioxide nanomaterial

A technology of nanomaterials and silica, which is applied in the field of preparation of hollow silica nanomaterials, can solve problems such as uneven particle size, unsuitability for large-scale production, and irregular shape of materials, and achieve easy modification of the dispersed surface, shape The effect of controllable appearance and structure, uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

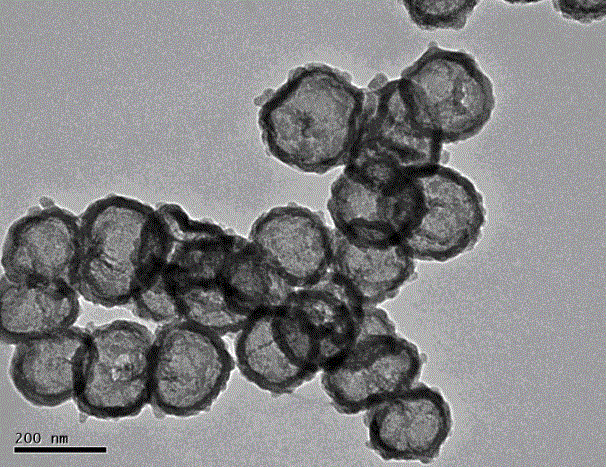

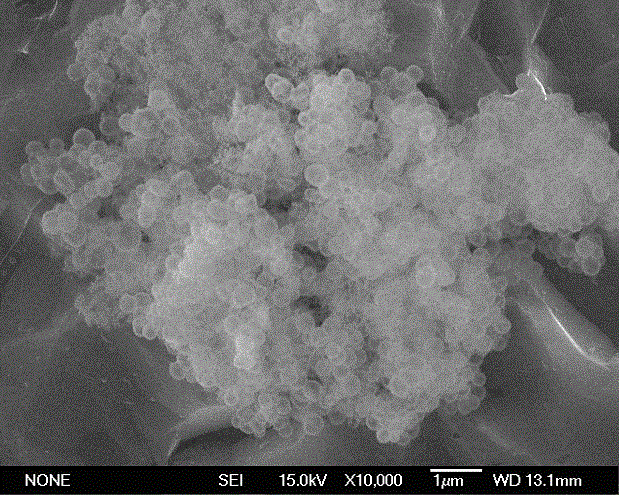

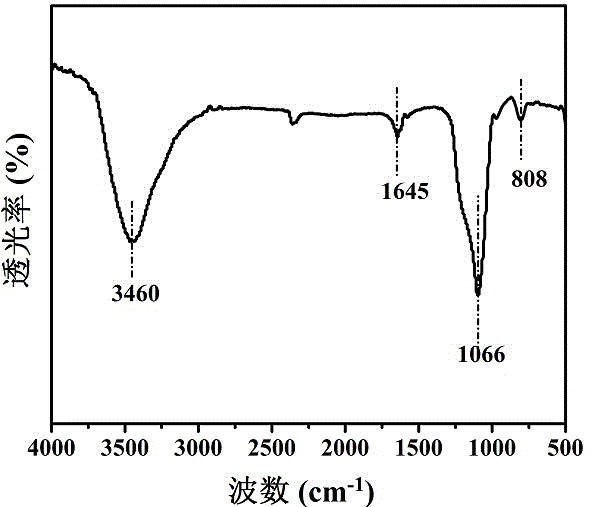

[0018] a. First prepare carbon spheres according to the existing known technology: Weigh 1.98 g of glucose with an electronic balance, add 20 mL of deionized water to sonicate until dissolved, and pour it into a 100 mL autoclave lined with polytetrafluoroethylene , reacted at 180 °C for 6 h, after the reaction was completed, the product was taken out from the reactor, centrifuged with ethanol and deionized water, washed, and dried at 60 °C to obtain a particle size of 180 nm Left and right carbon spheres with uniform shape;

[0019] b. Dissolve 50 mg of prepared carbon spheres in 20 mL of ethanol, then add 100 μL of 3-aminopropyltriethoxysilane (APTES), and stir at room temperature for 2 h;

[0020] c. Add 100 μL tetraethyl orthosilicate (TEOS) and 250 μL ammonia water (NH 3 ·H 2 O, 25~28 wt%), stirred at room temperature for 12 h and then centrifuged;

[0021] d. Dissolve the centrifuged product in 18 mL deionized water, add 0.0364 g cetyltrimethylammonium bromide (CTAB), ...

Embodiment 2

[0024] Example 2: The preparation process and steps of this example are basically the same as those of Example, the difference lies in step b:

[0025] 50 mg of the prepared carbon spheres were dissolved in 20 mL of ethanol without adding 3-aminopropyltriethoxysilane (APTES), and stirred at room temperature for 2 h.

[0026] The result obtained is quite different from the morphology of Example 1, a complete hollow spherical structure cannot be formed, the surface has many wrinkles, and the agglomeration is serious.

Embodiment 3

[0028] The preparation process and steps of this embodiment are basically the same as in Example 1, except that the d step:

[0029] Dissolve the centrifuged product in 18 mL deionized water, add 0.9 mL 0.001M NaOH, stir well, add 200 μL TEOS dropwise, and stir for 2 h; no cetyltrimethylammonium bromide (CTAB ).

[0030] The obtained result is quite different from the morphology of Example 1, and the product is a solid silica sphere with non-uniform particle size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com