Method for preparing nanometer ferroferric oxide by taking waterworks sludge as raw material

A technology of ferric tetroxide and water supply sludge, applied in iron oxide/iron hydroxide, nanotechnology for material and surface science, nanotechnology, etc., can solve the problem that the composition of iron salt coagulant cannot be fully utilized, etc. problems, to avoid secondary pollution hazards, widely used, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

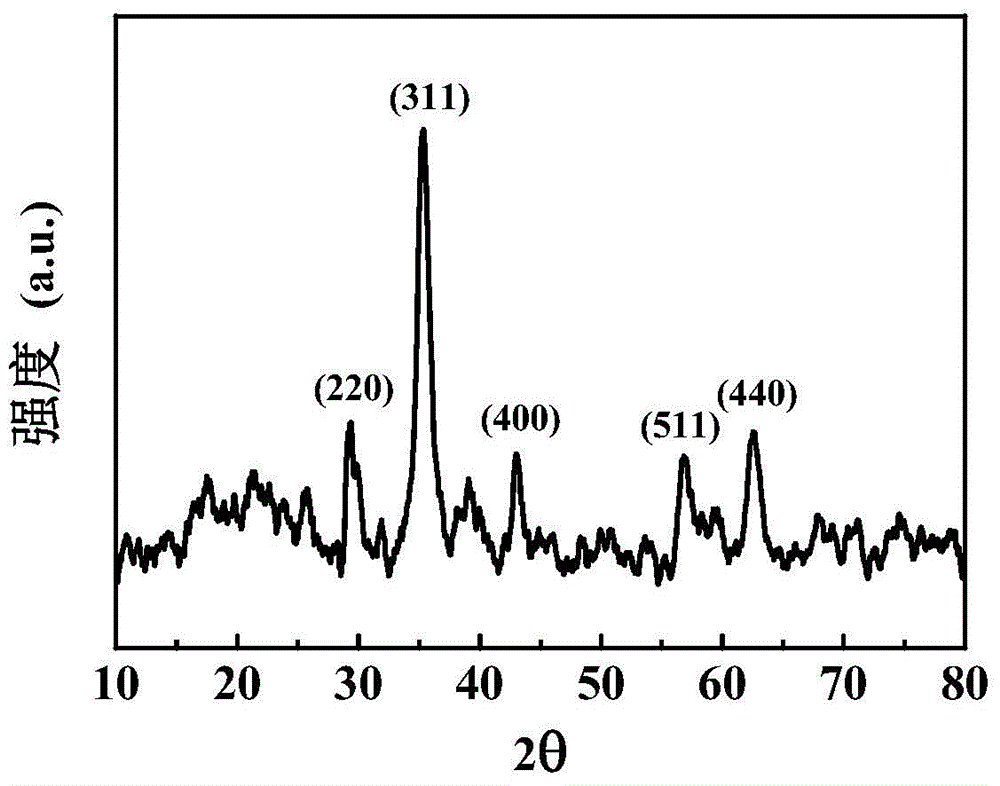

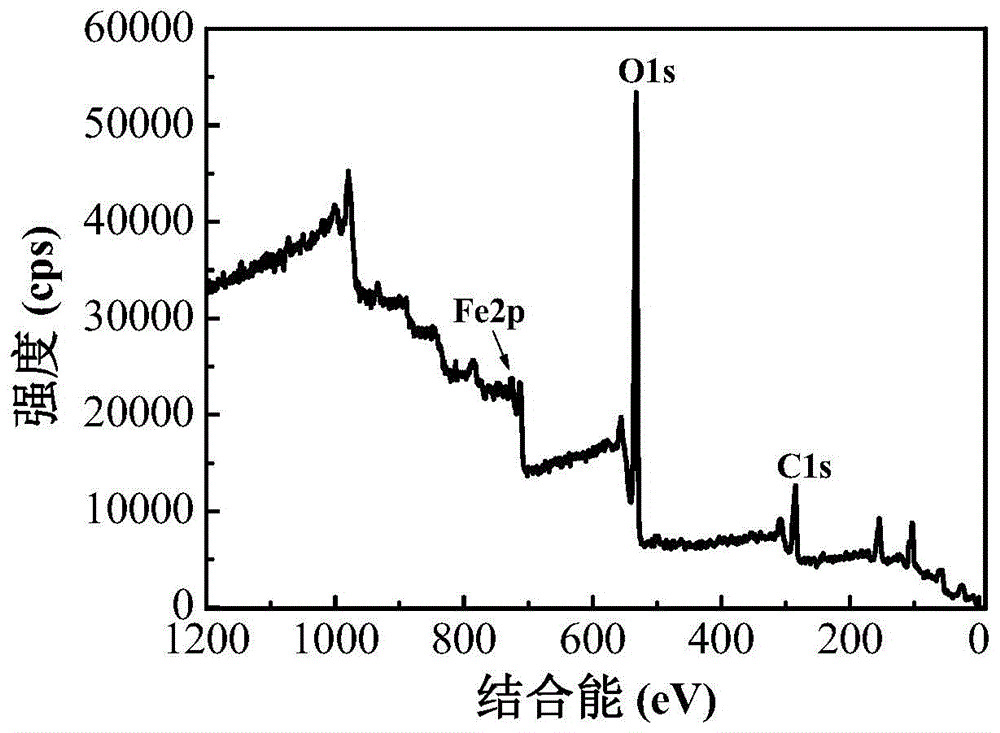

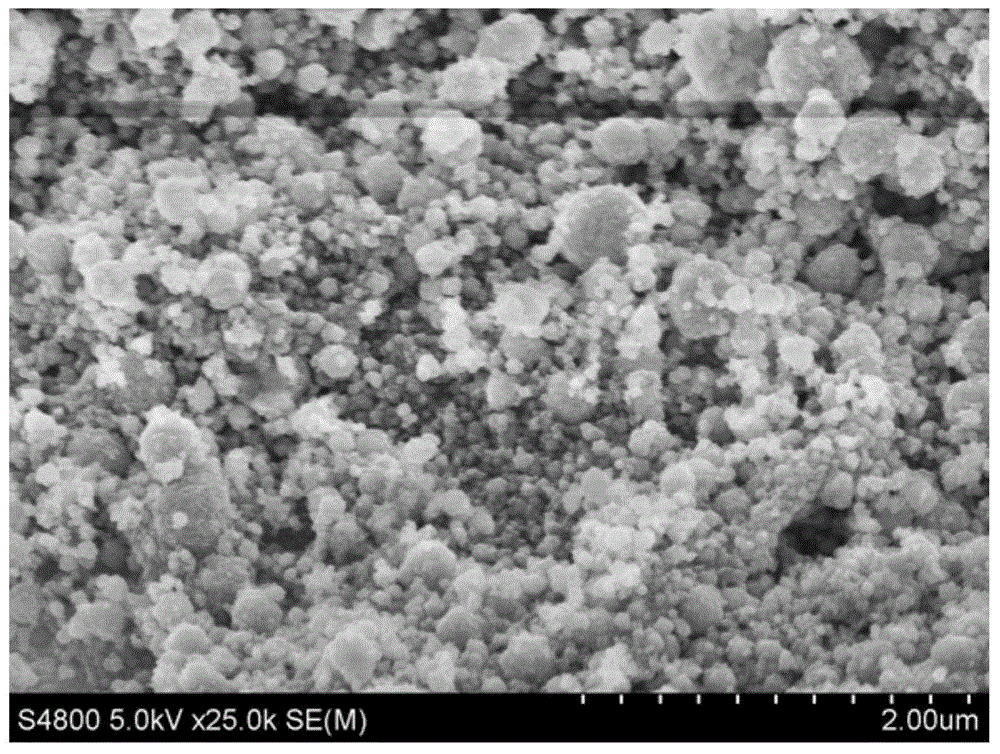

[0021] Specific embodiment one: this embodiment is a kind of method for preparing nano-ferric oxide ferric oxide with water supply sludge as raw material, specifically completes according to the following steps: 1. Preparation of water supply sludge powder: first, water supply sludge is naturally dried, Then grind to a particle size of less than 100 μm to obtain the water supply sludge powder; 2. Roasting: Put the water supply sludge powder into a box-type electric furnace, heat up from room temperature to 400-900 °C at a heating rate of 5 °C / min, and Roast at 400-900°C for 1 hour, then cool naturally to room temperature to obtain roasted feedwater sludge; 3. Acid leaching extraction: add the roasted feedwater sludge to acid at a solid-to-liquid ratio of 1:20, and stir at a stirring speed 400r / min and acid leaching temperature of 50-90°C for 1h-3h, then use a vacuum filter for vacuum filtration, then use distilled water as detergent, combined with vacuum filtration to wash the ...

specific Embodiment approach 2

[0025] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the water supply sludge described in step 1 is sludge from a sedimentation tank of a water purification plant. Others are the same as the first embodiment.

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the acid described in Step 3 is hydrochloric acid with a concentration of 2 mol / L. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com